Silica sand crusher for Silica,Marble,Granite mini sand making machine

Product Description♥Basic description of Granite mini sand making machine:

Vsi series high efficient vertical shaft impact type system sand machine in road building sand, sand optimal as appropriate. Its wide range of USES, performance has reached the international 5-15 Tons per hour,fine silica sand crusher for Silica,Marble,Granite mini sand making machine level, is currently the most effective, practical and reliable crushed stone machine, especially suitable for producing abrasive, fire-proof material, cement, quartz sand, steel grit, slag powder, copper ore, iron ore, gold ore, concrete aggregate, asphalt aggregate finely with a variety of hard and brittle materials such as crusher, is a highly efficient, energy-saving gravel sand making equipment, 50% energy saving than the traditional sand making machine, sand equipment is advanced in the world.

♥Feactures of Granite mini sand making machine:

1. The vsi series high efficient vertical shaft impact type system sand machine is the new development in the ninety s, fine gravel equipment, widely used in the world at present place of cone crusher, roller machine, ball mill machine.

2. The novel structure, unique, smooth operation, simple structure, operation and maintenance, easy installation, low cost.

3. Small energy consumption, high output, broken than large, with functions of finely, coarse grinding.

4. The equipment is small in size, easy operation, convenient installation and maintenance. High efficiency and energy saving, high crushing efficiency. Large quantity, high output -- -- -- -- -- 50-500 tons/hour, compared with the sand under the same power system equipment, production increased by 35%. And the performance is stable.

5. Plastic function, cubic shaped products, large packing density, through the broken material capability is strong, small affected by material moisture, moisture content is 8%, the size and the shape of the finished product is good -- -- -- -- -- a multi body six sides, and the reasonable distribution, special use and the mechanism of sand and stone plastic. After a lot of customers to use evidence than other similar power system equipment sand, plastic composite effect increased by 30%.

6. The production process, the stone can protect the underlying formation, fuselage without wear, durable, can be broken hard, hard material (such as corundum, sintered aluminium vanadium and soil, etc.).

7. A few easy wear parts made with very hard wear-resisting material, small volume, light weight, easy to replace parts, products are cube, small iron pollution, low wearing parts consumption -- -- -- -- -- - the ideal impact crushing material impact velocity, impact Angle, the most reasonable design and less friction wear parts, 30% lower than conventional equipment running cost, reduces the impact of sand making machine use cost directly, greatly improve the machine's margins.

8. Light weight, installation, portable installation, etc.

♥Working principle of Granite mini sand making machine:

all materials into system sand machine into the hopper, the center of the feed opening into the high speed rotating sling wheel, within the sling wheel is accelerated rapidly, its acceleration can be up to several times the gravitational acceleration, and high-speed throw from the left wheel, first with the rebound after free fall impact the other part of the material, then hit with lining material (stone hit stone) or counter piece of stone (iron), bounced inclined upward shocks to the top of the vortex chamber, and change the direction of movement, deflecting downward movement, and the material impact emitted from the impeller passage to form a continuous material. In this way, a piece of the material in the vortex broken cavity by two chances to many times the impact, friction, and grinding crushing effect. Be broken material by bottom discharging mouth eduction.

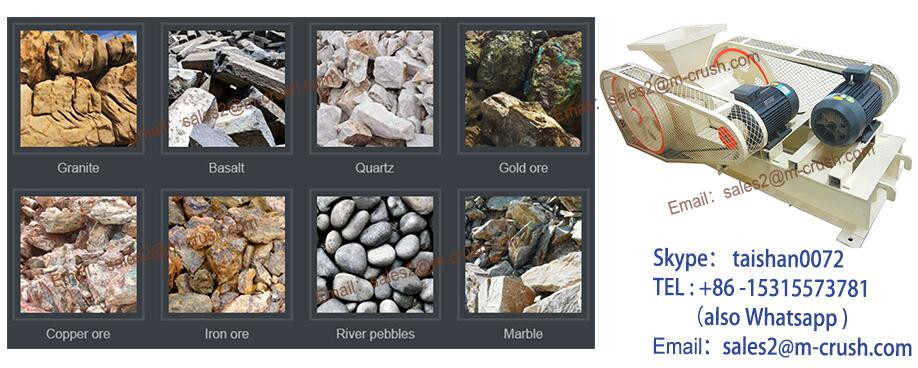

♥Pictures of VSI sand maker:

Raw materials

Complete sand making line

♥Parameter of Granite mini sand making machine:

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | ||

| Capacity (t/h) |

Center and Sides Feeding | 120-180 | 200-260 | 300-380 | 450-520 | |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | ||

| Max. Feeding Size (mm) | Soft Material | 35 | 40 | 45 | 50 | |

| Hard Material | 30 | 35 | 40 | 45 | ||

| Rotation Speed(rpm) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | ||

| Double Motor Power (kw) | 110 | 180 | 264 | 400 | ||

| Overall Dimension L×W×H (mm) |

3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | ||

| Weight (t) | 7.8 | 10.3 | 16 | 25.6 | ||

| Vibrating Sensor | Inspection Range: 0.1-20mm/s Continual Adjustment | |||||

| Hydraulic Oil Pump | Motor Power of Double Oil Pump(Kw) | 2×0.31kw | ||||

| Overall Dimension L×W×H (mm) |

820×520×1270 | |||||

| Power of Oil Tank Heater | 2KW | |||||

Packaging & Shipping

Export standard container 20GP OR 40GP,40HQ,the spare parts in wooden case for artificial sand crusher.

1) Pre-sale service:Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export.

3) After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

FAQ

Q:Instalation

A:At the client’s request, hengji can provide installation Technicians to supervise and assist in the assembly and commissioning of the equipment. Travel and accommodation costs, plus US$50 per day per man to be met by the client.

Q:Payment

A:30% by TT as deposit on signing the contract, 70% by as final payment of balance after the client’s satisfactory inspection of the equipment prior to the goods leaving the hengji factory.

Q: What about Warranty? what will we do if the machine is broken down

A:The warranty period for all of hengji structural and mechanical equipment is one year. The warranty period for all

electric motors is half one year. Wear parts are not covered by warranty unless the component part is found to be flawed.

Q: What should we need to do for if we want to get a best quatation

A: Hi, if you want us recommend a suitable type for you ,please let us know as follows:1).the capacity (tons per hour ) 2).output size 3).stone typeQ: What could you help me to do for the business ?A: Many thanks for your trust , we can provide you with proposal chart for complete production lines ,

spot inspection and operator traning according to your demands and the conditions of applied spot , we can help you choose the right equipments ,drilling rig ,loader ,trucks ,excavators and so on .

Q:What's your After sales sereive

A:All equipment manufactured by hengji is of the highest standard and very rarely have our clients experienced any mechanical problems. Should any problems occur, our team of Engineers and Technicians will respond within12 hours of notice by the client.

Q:Delivery time

A:Standard delivery time for stationary crusher plant is 30 days from receipt of deposit.the mobile crusher plant is 45 days,

Company Information5-15 Tons per hour,fine silica sand crusher for Silica,Marble,Granite mini sand making machine City Jinlong Heng Ji Heavy Machinery Co., Ltd. is a professional production of large and medium crushing, grinding, sand making equipment , research, production, marketing trinity of the private sector. Company headquarters is located in a blend of traditional and innovative mechanical 5-15 Tons per hour,fine silica sand crusher for Silica,Marble,Granite mini sand making machine City Industrial Development Zone , over the years , the company adhering to the scientific management of modern enterprises , precision manufacturing , forge ahead , innovation, rapid rise to become the leader in equipment manufacturing deserved.

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.5-15 Tons per hour,fine silica sand crusher for Silica,Marble,Granite mini sand making machine grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,5-15 Tons per hour,fine silica sand crusher for Silica,Marble,Granite mini sand making machine coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and 5-15 Tons per hour,fine silica sand crusher for Silica,Marble,Granite mini sand making machine thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.5-15 Tons per hour,fine silica sand crusher for Silica,Marble,Granite mini sand making machine adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK