ISO BV SGS Certified Stone Fine Powder Crusher

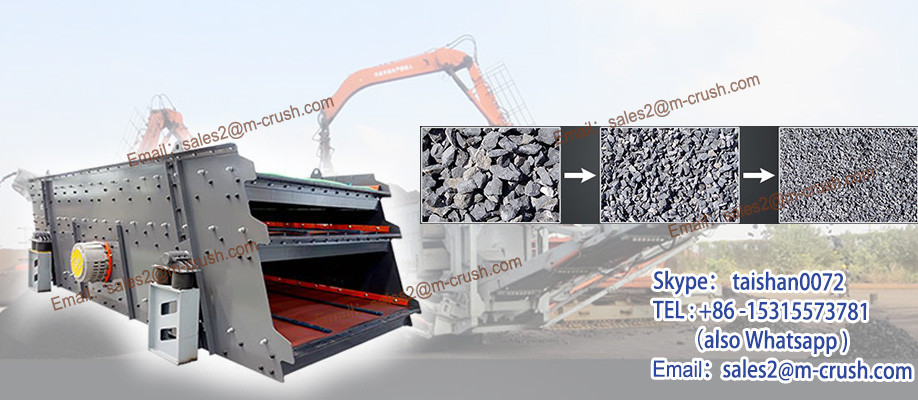

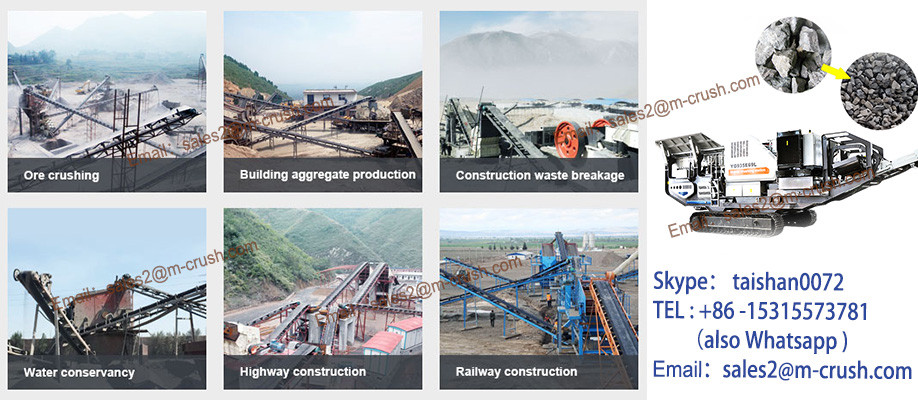

Product Description Introduction of High Quality Fine CrusherThe raw material is transferred to JawCrusher for primary crushing by Vibrating Feeder, then the crushed materialsare transferred to sand-making machine through Belt Conveyor for secondarycrushing. The crushed materials will be transferred to the vibrating screen.The materials with suitable size will be transferred to Sand Washing Machine,after being washed, then clean final products will be discharged. The otherswith unsuitable size will be screened from vibrating screen, then will betransferred to the sand-making machine, this forms a closed circuit manifoldcycles.

Our company independently developed DPC Finecrusher, JXP fine crusher, PCZ fine crusher with Jinma patent; they can be usedin the secondary crush, with final products size of less than 5mm. The whole production line can bereduced to first crush and secondary crush.

Advantages of PXJ fine crusher sand making machine:

the small size materials, grain-uniform capacity, hammer, long life, supporting small power, and change three for two broken broken, process simplification, simple structure, easy maintenance, the smooth running and so on

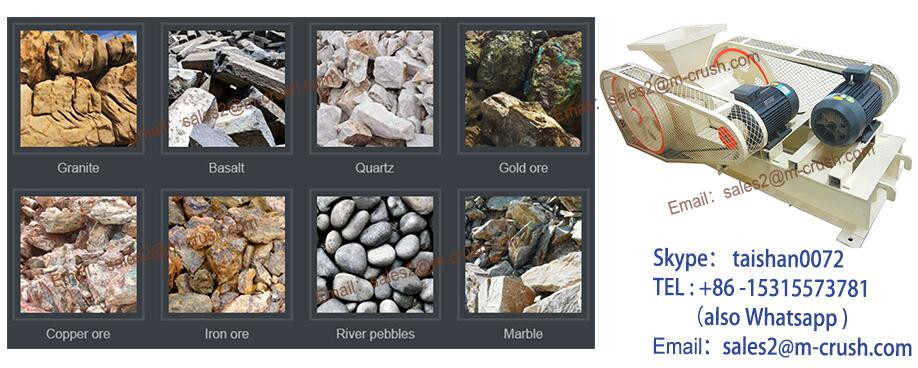

Application of Fine Powder Crusher

Equipment investment lower than the same size of the traditional technique and equipment 35% -50%, higher than the same scale output efficiency of traditional technique and equipment 35% -50% (limestone as an example: one product size ≤ 5 mm accounting for 85 percent). Long-term maintenance costs run less than the same size of the traditional technique and equipment 35% -50%, widely used mechanism aggregate, cement, Refractories, and metallurgical industries.

|

Rotor work diameter * width (mm) |

Feeding Port Dimension (mm) |

maximum Feeding Granularity (mm) |

Discharging Granularity (mm) |

Grate on the expected width adjustment (mm) |

output (t/h) |

Motor Power (kw) |

|

Clinker |

Limestone |

||||||

Ø800×400 |

400×185 |

5-20 |

20-30 |

35-45 |

37-45 |

||

Ø800×600 |

500×250 |

5-20 |

35-40 |

45-55 |

45-55 |

||

Ø800×800 |

550×330 |

5-20 |

35-45 |

55-65 |

45-55 |

||

Ø1000×1000 |

1000×350 |

5-20 |

45-55 |

65-75 |

55-75 |

||

Ø1200×1000 |

1200×400 |

5-20 |

55-80 |

75-100 |

100-110 |

||

Ø1200×1200 |

1200×450 |

5-20 |

75--90 |

90-100 |

100-132 |

||

Ø1400×1400 |

1500×500 |

5-20 |

90--130 |

100-150 |

160 |

||

Ø1600×1600 |

1600×550 |

5-20 |

170-210 |

190-250 |

250 |

||

Ø1800×1800 |

1800×800 |

5-20 |

250-270 |

280-310 |

315 |

||

More picture of PXJ fine crusher

Heavy type rotor design and strict testing method to guarantee high quality rotor.

Packaging & Shipping

Packaging Details:

1. Main machine is packed with plastic wrap or steel box, depends on machine weight.

2. Electric motor is packed with steel box or wood box.

3. Motor control is packed with carton box.

4. Loaded container at factory.

Delivery Detail:

in 7 working days after down payment

Technological support:

Jinma insists on providing clients with overall solutions from equipment recommendation to debugging and installation, worker training, technical support and maintenance.

Our high reputed engineers and technicians can provide users with overall technical support, including material characteristic analysis, crushing test and process optimization of flow simulation.

Our professional engineers will design the most reasonable scheme for the real production line.

Introduction of our company

Support & service from Zhengzhou Jinma Mining Machinery Co., Ltd.

1. Jinma provide the design, process diagram and foundation drawings according to clients' request.

2. Clients are welcome to inspect the equipment when the equipment are ready to delivery.

3. Equipment will be delivered with English Manuals and technical drawings

4. Engineers available to service machinery overseas, to make the layout design, foundations, guide the installation, commissioning run test, training workers, etc.

5.The equipment ordered from jinma will be guaranteed within 2 years since the day of purchasing if the problem is due to the equipment’s quality. If there is big quality problem with the equipment, the seller will discuss with the buyer and offer proposals to solve the problems within 72 hours since the notice from buyer.

6. Offer spares for the equipment within 10 years.

Our Factory & workshop

Certifications of our company

Our overseas clients came to visit products

FAQ

Q: Can I visit your factory ?

A: Of course, There are many domestic and international clients visit our factory every year

Q: How is your quality of the machine ?

A: Our products are manufactured strictly according to national and international standard, and we take a test on every machine before delivery.

Q: How about your price ?

A: Yes, we are factory and be able to give you the lowest price than market one, and we have a principal that “ for saving time and absolutely honest business attitude,we quote you as low as possible, and discount can be given according to quantity”.

Q: Guaranteed ?

A: If products’ quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

Q: Do you provide after-sales services ?

A: Sure, we have a professional technical team to slove your problem timely and thoroughly.

Q: Do you have other related products ?

A: Yes, we manufacture all types of crusher, sand making machine, ball mill, magnetic separator, flotation

machine, ect

Contact WayFor the more details of machine and future cooperation. Pls contact us if you feel free.

we sincerely welcome clients from all over the world to come for a visit, and establish long term win-win cooperation.

Company |

Zhengzhou Jinma Mining Machinery Co., Ltd |

Name |

Tracy Li |

| L898067280 | |

Mobile |

+86 - 18837121898 |

Skype |

+86 - 18837121898 |

18837121898 |

|

| Tel | 86-ISO BV SGS Certified Stone Fine Powder Crusher67511065 |

| Web | https://zzjmjx.en.ISO BV SGS Certified Stone Fine Powder Crusher.com |

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.ISO BV SGS Certified Stone Fine Powder Crusher grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,ISO BV SGS Certified Stone Fine Powder Crusher coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and ISO BV SGS Certified Stone Fine Powder Crusher thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.ISO BV SGS Certified Stone Fine Powder Crusher adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK