Dura-Shred Single Shaft shredder

Outstanding expert comprehensive solution in solid waste recycling

=============================================================================

( Plastic recycling equipment painting coating electric fine crusher )

[TIS Series]

—— Specially designed for large volume material of shredding machine

Feature

• Internal hydraulic pusher

• Adjustable, high frequency of pushing

• Significant increase in the internal space

• Closed cutting chamber to avoid material spillage

• Compared with the standard shredder, covers less space.

Application

• Recycling big volume parts such as IBC pallets and big capacity plastic barrel

• In house recycling in big volume blow moulding operations

• General recycling in the plastic and wood industry

Can be equipped with a wear package for processing of highly abrasive or filled materials.

=============================================================================

[TRS Serie]

——Tobular product shredders

Feature

• High throughput rates

• Powerful hydraulic pusher

• big diameter rotor (up to 1500 mm)

• Virtually risk free, automated operation

• Drive by Low-RPM, high-torque gearbox

• Feeding of bundles or nested pipes and profiles

• No pre cutting of pipes of up to 1200 mm diameter necessary

Application

• Shredding of large diameter pipes or bundles of smaller pipes and profiles made from HDPE, PP and all kinds of PVC.

• Recycling of other plastic parts, such as large lumps, stacked wheelie bins and pallets.

In combination with other DURA-SHRED size reduction equipment such as granulators and

pulverizers we are able to provide a complete turn key recycling solution.

=============================================================================

[TSH Series]

——Heavy-duty wet crusher series

Feature

• The blades can be adjusted outside conveniently and quickly

• Unique designed deflection wedge can make the crusher more applicable.

• Various rotors are optional

• The upper and lower chamber are both sealed to prevent leakage of water

• The high force feeding hopper is specially designed for packaged PET bottle and film

• Blades are all specially treated to Plastic recycling equipment painting coating electric fine crusher the lifetime

Application

Whole plastics industry, especially suitable for packaged PET bottles and film’s recycling and

cleaning.

=============================================================================

[TSS Series]

——Professional shredder for Plastic scraps, Paper, Non-ferrous

Feature

• Two speed hydraulic comes standard

• Powerful hydraulic swing type pusher

• Automatic operated, more safer

• Low speed, high torque gear drive

• Bolted in drive shafts, convenient to replace

• Smaller footprint compared to traditional shredders with horizontal pushers

Application

In house and general recycling, electronic waste and post-consumer, waste handling.

=============================================================================

[TXS Series]

——Specially designed for high capacity production

Feature

• High capacity

• Low speed, high torque gear drive

• Powerful two speed hydraulic swing type pusher

• Heavy Duty design & High throughput rates

• Suitable for very large and heavy parts

• big diameter rotor (750 mm)

Applicaiton

• Household appliances, large heavy material & large tyre recycling.

• The most demanding and high throughput applications in recycling industries.

=============================================================================

Company Information

Certifications

Our Services

Our Services

A. Warranty: 1 year warranty for main parts, 20 years for the heavy duty machine.

B. After sale service: 2 or 3 engineers will be sent to help install the machines.

C. OEM & ODM are available by engineering team with 15 years experiences.

D. Turn-Key service, available to handle all the work including shipment, customs clearance, etc.

E. Various end product samples can be offered for free.

F. Regular return visit after sale.

G. Profits can be shared if client introduce new customer from their market.

FAQ

Q1: How to choose the suitable machine?

A1: Please answer first:

a: What material do you want to shred?

b: What is the usage of the crushing material?

c: How many tons per hour do you demand?

After that, the suitable machine could been introduced to you.

Q2: What about the shipping and package?

A2: We arrange shipment according to your requirements. It is included in our TURNKEY service.

Q3: Can I visit your company or factory?

A3: Of course you can.

Our headquarter is in Shanghai city.

Our production plant is in Wuxi city, Jiangsu province.

And when you fly to China, we could pick you up and afford your local transportation charges.

Q4: What's the relationships between tqwinner and dura-shred?

A4: They are 2 brands belonging to the same group.

Dura-Shred is registered in Wuxi;

Tqwinner in Shanghai.

Our headoffice and marketing team are located in Shanghai.

=======================================================================================

ANY OTHER INFORMATIONS OR QUESTIONS, JUST FEEL FREE TO CONTACT US !!!

YOU MAY ALSO LIKE THE FOLLOWING PRODUCTS LIKE 90% OF THE OTHER VISITORS:

|

|

|

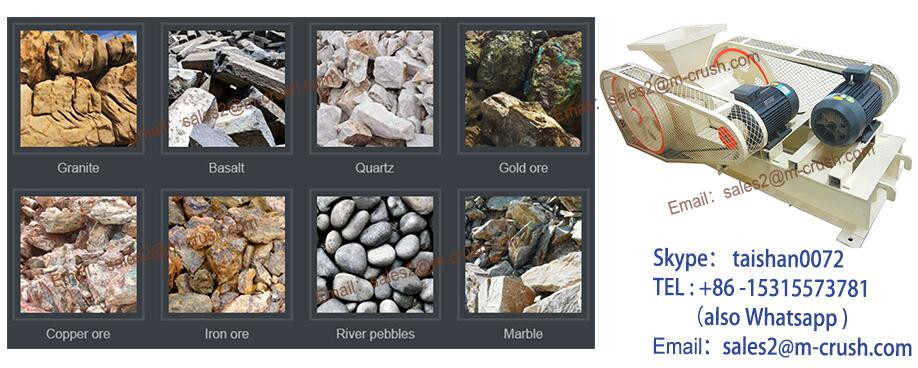

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.Plastic recycling equipment painting coating electric fine crusher grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,Plastic recycling equipment painting coating electric fine crusher coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and Plastic recycling equipment painting coating electric fine crusher thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.Plastic recycling equipment painting coating electric fine crusher adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK