2017 HSM New Design High Quality and Inexpensive Fine Rock Jaw Crusher Sale

Fine Rock Crusher Introduction:

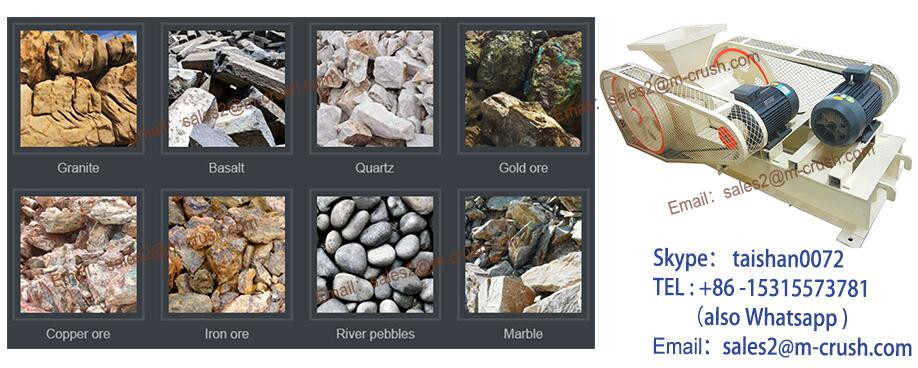

Jaw Crusher is one of the most popular stone crusher in the world, Jaw Crusher is ideally suitable for primary and secondary crushing. The highest anti-pressure strength of crushed material is 320MPa.

Jaw Crusher is widely used in mining, metallurgy, construction, highway, railroad, and chemistry industries and etc. Many models are available according to your different fineness requirements.

Working Principle of Fine Rock Crusher

Motor drives belt and belt pulley, makes moving jaw up and down through eccentric shaft. When the moving jaw is up, the angle between lining plate and moving jaw becomes large, and this will push moving jaw plate close to the fixed jaw plate. During this process, the material is crushed and ground, thus the crushing will be done

When the moving jaw is down, the angle between lining plate and moving jaw becomes small, the moving jaw plate will leave the fixed jaw plate on account of the effect of pulling bar and spring, and then the crushed material will be discharged from the lower opening of the crushing room.

With the motor continuously rotating and the material periodically crushed and discharged by the crusher, the mass production can be realized.

Fine Rock Crusher benefit

–Excellence in casting engineering

–Excellent material intake capacity

–Easy installation & maintenance

–High production and reduction

–Reliability, high availability

Technical Parameter Fine Rock Crusher

| Model | max feeding size | discharding size | capacity | spindle speed | motor power | weight | dimension |

| PE150X250 | 125 | 10-40 | 1-3 | 285 | 5.5-7.5 | 0.7 | 922x745x933 |

| PE200X300 | 165 | 20-70 | 2-8 | 265 | 11 | 0.8 | 1056X1100X1120 |

| PE250X400 | 210 | 20-80 | 5-20 | 310 | 15-18.5 | 3 | 1108x1142x1392 |

| PE400X600 | 340 | 40-90 | 10-40 | 275 | 30 | 7.2 | 1700X1732X1392 |

| PE350X750 | 290 | 30-50 | 20-50 | 300 | 37 | 8.9 | 1900X1806X1808 |

| PE500X750 | 425 | 50-100 | 34-68 | 275 | 55 | 11.32 | 2050X186001808 |

| PE600X900 | 480 | 75-200 | 40-120 | 255 | 75 | 17.6 | 2792X2168X2250 |

| PE750X1060 | 630 | 80-200 | 80-160 | 250 | 90 | 30.53 | 4180X2560X3070 |

| PE900X1200 | 750 | 100-200 | 110-200 | 250 | 110 | 50 | 5200X2900X3500 |

| PE1000X1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480X2876X3330 |

| PE1200X1500 | 1020 | 150-300 | 400-800 | 180 | 160 | 100 | 4200X3300X3500 |

| PEX150X750 | 125 | 10-40 | 5-15 | 300 | 15 | 3.5 | 1200X1480X1180 |

| PEX250X1000 | 210 | 15-65 | 10-32 | 300 | 30 | 4.35 | 1580X1992X1380 |

| PEX250X1200 | 210 | 15-60 | 12-38 | 300 | 37 | 8.7 | 1730X2192X1380 |

| PEX300X1300 | 250 | 20-90 | 16-65 | 300 | 45-55 | 11.6 | 1930X2400X1747 |

Packaging & Shipping

HSM Machinery offers various ways of package, fumigation-free wooden cases, steel plate cases, or as the clients' request. Most of the time, the equipment will be loaded to the containers in the factory. HSM workers make sure all equipment are steady and fixed before close the door of the container, there will be no damage during transporation and shipment. Following pictures are typical package, reinforcement in the container, and delivery from HSM Machinery.

Our Services

Pre-sale services

Based on the clients’ request and budget, we will offer equipment pictures, working site videos, plant processing diagram, assemble drawings, foundation drawings, and plant layout. Clients are welcome to visit our factory, also our equipment working site from former clients. We will arrange cars, hotels and translators for the visiting customers.

-Sale services

Our experienced technicians is available on the phone also the internet, clients can get instance guidance by telephone, email, online service anytime, anywhere. As clients’ request, we will send technician to the mine site to guide the installation, trial run test, and training operators until the plant works normally.

-After-sale services

Normally, the equipment warranty is 18 months since installation, but can extend as long as 24 months as the clients’ request. Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed. To establish long term cooperation, we will regularly call and email our clients, to check the equipment working condition, offer suggestions for maintenance, and if necessary we will pay a visit to clients to solve the problems caused during equipment working.

Company Information

2017 HSM New Design High Quality and Inexpensive Fine Rock Jaw Crusher Sale Huashengming Machinery Co., Ltd is a high-technology enterprise in 2017 HSM New Design High Quality and Inexpensive Fine Rock Jaw Crusher Sale City. For the past twenty years, Huashengming has been developing and manufacturing machines for the natural stone and recycling industry. One of the most important equipments of Huashengming product range is the crushing and screening crusher. Huashengming crushers are used for soft to medium hard natural stone and recycle construction waste.

In order to offer our customers with more suitable crushers, Huashengming designed crushers, which can do a lot more than just high reduction. The 2017 HSM New Design High Quality and Inexpensive Fine Rock Jaw Crusher Sale today is on cost, the environment, availability and, above all, the quality of the end product. Simply crushing material is an easy process; crushing material so that the grain size, grain distribution and cleanliness also meet the high standards of customers requires something more, which does justice to the performance of the crusher. Huashengming unites all characteristics in its crusher, supplementing them with a variety of useful details to create a machine which really sets the standard when it comes to operating efficiency and reliability.

Some products have achieved advanced level of international standards. We can supply a series service including projection design, flowchart design, standard or non-standard design and manufacture, installation and take trial run.

Our company owns a service team that has rich experience and skillful technique. According to customers' demand, we supply the services in a flexible way not only the traditional services but also the Internet on-line services. We try our best to carve out market and provide services all the time.

Before customers' purchase, we will send our engineers to customers' site to design the best flow chart; after purchase, we will send the engineer to guide to install the machine, take trial run. Try our best to provide our customers with service of high quality and high efficiency.

Welcome to visit my web site http://www.050909.com

http://www.hsmmachinery.com http://www.rollscrusher.com

FAQ

PAYMENT:

1: 30% of the total amount shall be paid by T/T as deposit ,balance have to be paid by TT or L/C before delivery.

2: 100% irrevocable letter of credit at sight

DELIVERY TIME :

7-10 working days after receiving the advance payment.

PACKING:

Machines will be through rusty and moist-proof before delivery; small parts are packed into wooden crates;larger parts are wrapped by plastic sheeting

INSTALLATION :

If required, one or more engineer/engineers will be sent to guide the installation and commissioning of machines; the buyer shall prepare the materials and tools needed,and offer necessary assistance.The actual expenses include accommodation, meal and traveling fee of the engineer,and insurance also should be paid by the buyer. Every engineer should be paid 100 USD per day.

WHY HSM IS POPULAR IN THE WORLD ?

The reason:The outstanding features of from HSM.

1.Easy to transport

2.Greatly reduce material transportation cost

3.Wide applications

4.Reliable performance and convenient maintenance

5.Customized production and flexible configuration

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.2017 HSM New Design High Quality and Inexpensive Fine Rock Jaw Crusher Sale grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,2017 HSM New Design High Quality and Inexpensive Fine Rock Jaw Crusher Sale coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and 2017 HSM New Design High Quality and Inexpensive Fine Rock Jaw Crusher Sale thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.2017 HSM New Design High Quality and Inexpensive Fine Rock Jaw Crusher Sale adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK