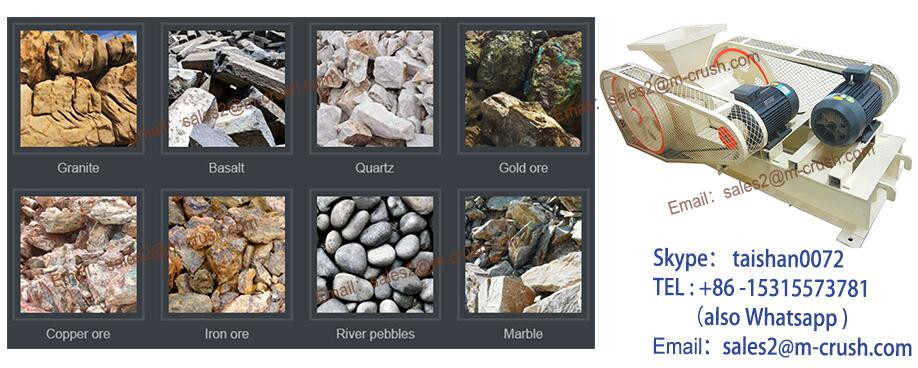

Applications of limestone fine roller crusher:

1). limestone fine roller crusher has many names such as roller crusher, double-roller crusher and double-geared roller crusher.

2).limestone fine roller crusher is mainly made up of roller, supporting part of the bearing, clamping and adjustment means, drive device and so on.

3). limestone fine roller crusher can be used for the medium and fine crushing of all kinds of ores and rocks with high and medium hardness in many industrial departments such as ore beneficiation, chemistry, cement, refractory, abrasive materials and building materials.

Working Principle of limestone fine roller crusher:

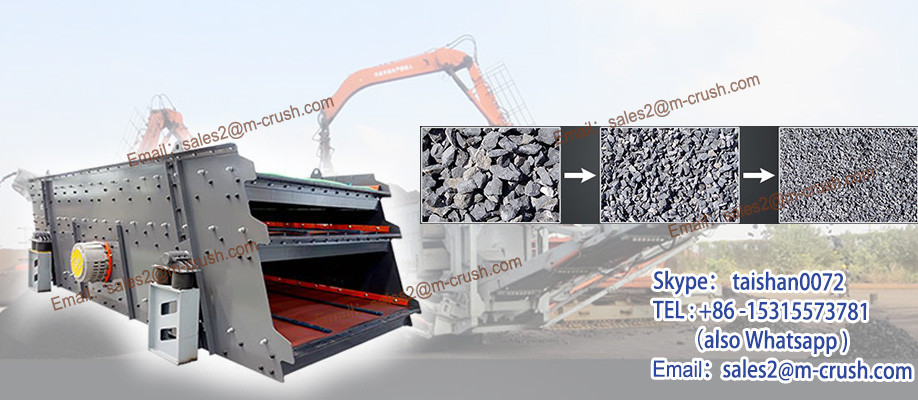

limestone fine roller crusher consists of roll wheel, roll bearing, pressing device, adjusting device and driving device etc. Discharging size adjustment: between two roller equipped with cuneate or gasket adjusting device, top of the wedge device capped with adjustment bolts. When the adjustment bolts pull upward wedge which will bear against the fixed wheel to make it deviate from the movable roller wheel, then the gap between wheels become large, discharging size become bigger, otherwise the opposite, gasket device is through the quantity or thickness to adjust the materials size.

When limestone fine roller crusher adding gaskets the gap between wheels become large, when reducing gaskets the gap between wheels become small, so the discharging size becomes small. Driving structure is two motors through triangle belt drive to grooved pulley which drag roller rotating according to relative direction. In crushing stage, material is broken by roll wheel; final product is discharged from chassis. For safety, transmission part should be installed safety guard according to actual situation.

Features of limestone fine roller crusher:

1). limestone fine roller crusher has the features of simple structure, and takes up smaller space, and the operation and maintenance of this machine is very convenient.

2). limestone fine roller crusher is equipped with safety protection device.

3).The operational cost is low, stable operation, high efficiency, saving energy, high crushing efficiency.

4).There is equipped dustproof plant inside the machine and the sealing ability is excellent, so that thereis little powder dust and lower working noises, so that the working environment is greatly improved.

5).The gap of the roll can be adjusted according to the requirement of the customers.

Parameter of limestone fine roller crusher:

Model |

Feeding size |

Discharging size(mm) |

Capacity |

Motor power |

Weight |

Dimension |

2PG400×250 |

≤2-8 |

2-10 |

2×5.5 |

1.3 |

2110×870×810 |

|

2PG610×400 |

≤2-20 |

5-20 |

2×15 |

3.9 |

3510×1420×1030 |

|

2PG750×500 |

≤2-25 |

10-40 |

2×18.5 |

9.5 |

4210×1630×1260 |

|

2PG800×600 |

≤2-25 |

12-45 |

2×22 |

10.8 |

4505×1780×1320 |

|

2PG1000×700 |

≤3-30 |

20-65 |

2×30 |

14.9 |

5310×2175×1HSM Professional Best Price limestone fine roller crusher |

|

2PG1200×800 |

≤3-35 |

35-80 |

2×37 |

25.5 |

6290×2270×1870 |

|

2PG1500×800 |

≤3-45 |

50-120 |

2×75 |

33.7 |

7460×2410×2290 |

|

2PG1600×1000 |

≤3-50 |

60-140 |

2×90 |

41.2 |

8220×2680×2475 |

Detailed Images

Company Information

HSM Professional Best Price limestone fine roller crusher Huashengming Heavy Machinery Factory are mainly produce crushing and mining equipment.

We have 20 years experience.Our products got ISO CE BV SGS certificate. If your are interested in any of our machine, pls feel free to contact us.

We will work with you to create a win-win situation, together to create the world famous brand of china.

Packing:

1.Rustproof and moisture proof before delivery.

2.Free fumigation plywood case for single machine,larger parts are wrapped by plastic sheeting.

3.Export standard container 20GP,40GP,40HQ,etc. for production line.

4.Other packaging according to your special requirement.

Shipping:

We usually accept EXW, FOB and CIF etc. terms.

1.By sea or by train. we have 20 years cooperate transport company. bestfreight, fast delivery.

2.Send B/L in 3-5 days after ship leaving.

3.will remind you before ship arrival.

1.Design most suitbale flow chart and layout freely according to your request.

2.Provide operating instruction and relative drawing.

3.We can send 1-2 technicians to the site for guiding the installation and commissioning.

4.We offer training service for free.

5.We offer the components with favorable price.

6.Lifetime Warranty.

1. Q: Can I visit your factory?

A: Yes. Many domestic and overseas customers visited our factory every year.

2. Q: What about the warranty of your equipment? Do you supply spare parts?

A: Our warranty is 2 years(24 months), and we can supply spare parts also.

3. Q: Do you provide after-sales service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

4. Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

5. Q: Do you provide producution flow chart?

A: Yes. Our experienced engineers are specialized in designing process flow for stone crushing plant and various ores beneficiation line.

6. Q: Can you test our sample raw material?

A: Yes. You can send your samples to us for testing and analysis.

7. Q: Have you made the whole stone crushing line?

A: Yes. We have made many large&small scale stone crushing line at home and abroad.

PAYMENT:

1.Accept T/T, L/C, Western Union, Money Gram or others payment terms.

2.20-30% in advance as down payment, the balance to be paid before delivery. We take pictures and testing videos of finished products before you pay the balance.

INSTALLATION:

If required, one or more engineer/engineers will be sent to guide the installation and commissioning of machines; the buyer shall prepare the materials and tools needed,and offer necessary assistance.The actual expenses include accommodation, meal and traveling fee of the engineer,and insurance also should be paid by the buyer. Every engineer should be paid 100 USD per day.

WARRANTY:

100% brand new when leaving the factory. The seller guarantee the quality of the machine (excluding wearing parts) for a period of one year from the date of trial run but not exceed 15 months from the date on which machine shipped out of the factory.

BANK DETAILS:

Beneficiary’s Bank Name: AGRICULTURAL BANK OF CHINA, HENAN, ZHENGZHOU BR.

Address: NO.50 LONGHAI ROAD ZHENGZHOU, HENAN, 450006 CHINA

SWIFT BIC:ABOCCNBJ160

HSM Professional Best Price limestone fine roller crusher GONG YI CITY HUA SHENG MING HEAVY INDUSTRY MACHINERY FACTORY

Account No: 16-021314040001166

Why HSM double roll crusher is popular in the world ?

The reason:The outstanding features of hammer crusher from HSM.

1.Easy to transport

2.Greatly reduce material transportation cost

3.Wide applications

4.Reliable performance and convenient maintenance

5.Customized production and flexible configuration

HSM insists on providing clients with overall solutions from equipment recommendation to debugging and installation, worker training, technical support and maintenance.

...

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.HSM Professional Best Price limestone fine roller crusher grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,HSM Professional Best Price limestone fine roller crusher coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and HSM Professional Best Price limestone fine roller crusher thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.HSM Professional Best Price limestone fine roller crusher adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK