Ultra-fine Crushing Machine HPGR for Magnesia ore

Luoyang Zhongyuan Mining Machine Manufacture Co.,Ltd. is located in Luoyang

Luoyang Zhongyuan Mining Machine Manufacture Co.,Ltd. is located in LuoyangCity, covering 30000 m2. Since established in 1986, it is specialized in developing and

manufacturing briquetting & compacting system, crushers, cement equipments, coal

machinery, conveying equipments, mixing equipments and other complete plant which

can be widely used in metallurgy, mine, building materials, chemical, coal, power and

urban garbage disposal industries. Our products have been exported to Southeast Asia,

Europe, Africa, Asia and other areas. The company has passed the ISO9001:2000. GY

series briquette machine has CE certificate. Equipments also could be tailored according

to customer’s requirements.Product

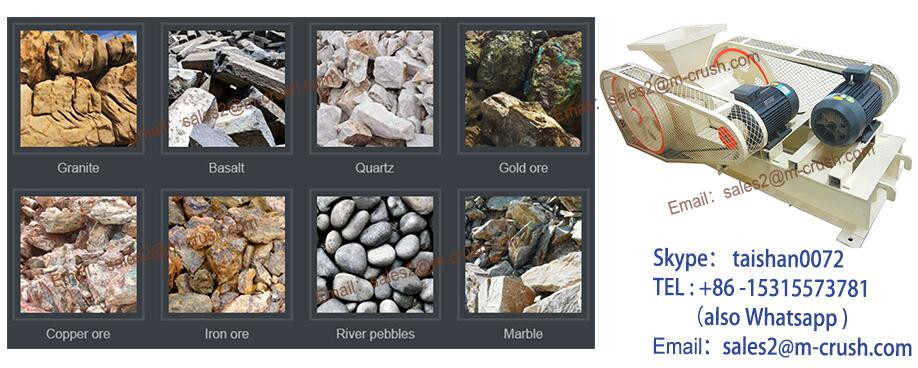

The GM series of high-pressure grinding roll are our independently developed new product through the innovative technology based on the technology from a Germany company. The equipment is consisted of 2 press rollers which are rotated in opposite direction but synchronously. The material is fed from the top of the rollers and enters into the gap between the rollers. The material will be crushed by the high pressure of rollers and discharged as a solid cake. It is mainly used for nonferrous metal ore such as bauxite, iron ore, and other materials such as bauxite, iron ore, iron ore concentrate and other materials such as fine crushing cement raw material, clinker, furnace slag, and limestone..

The GM series of high-pressure grinding roll are our independently developed new product through the innovative technology based on the technology from a Germany company. The equipment is consisted of 2 press rollers which are rotated in opposite direction but synchronously. The material is fed from the top of the rollers and enters into the gap between the rollers. The material will be crushed by the high pressure of rollers and discharged as a solid cake. It is mainly used for nonferrous metal ore such as bauxite, iron ore, and other materials such as bauxite, iron ore, iron ore concentrate and other materials such as fine crushing cement raw material, clinker, furnace slag, and limestone..

|

Model |

Roller dia.(mm) |

Roller width (mm) |

Power (kw) |

Feeding size(mm) |

Finished size (mm) |

Throughput (t/h) |

Weight (t) |

||

|

Metal ore (mm) |

Powdered Iron(cm2/g) |

Metal ore (mm) |

Powdered Iron(cm2/g) |

||||||

GM600-200 |

600 |

200 |

2X75 |

≤25 |

1100-1300 |

≤3 |

1400-1600 |

16-24 |

14 |

GM800-300 |

800 |

300 |

2X110 |

≤30 |

1100-1300 |

≤3 |

1400-1600 |

39-58 |

24 |

GM1000-300 |

1000 |

300 |

2X160 |

≤35 |

1100-1300 |

≤3 |

1400-1700 |

61-91 |

32 |

GM1000-400 |

1000 |

400 |

2X200 |

≤35 |

1100-1300 |

≤3 |

1400-1700 |

80-120 |

36 |

GM1000-500 |

1000 |

500 |

2X280 |

≤35 |

1100-1300 |

≤3 |

1400-1700 |

100-150 |

40 |

GM1200-500 |

1200 |

500 |

2X315 |

≤40 |

1100-1300 |

≤3 |

1600-1800 |

130-190 |

56 |

GM1200-630 |

1200 |

630 |

2X400 |

≤40 |

1100-1300 |

≤3 |

1600-1800 |

160-240 |

65 |

GM1200-800 |

1200 |

800 |

2X500 |

≤40 |

1100-1300 |

≤3 |

1600-1800 |

200-310 |

79 |

GM1400-800 |

1400 |

800 |

2X560 |

≤50 |

1100-1300 |

≤3 |

1600-1800 |

260-390 |

110 |

GM1400-1100 |

1400 |

1100 |

2X800 |

≤50 |

1100-1300 |

≤3 |

1600-1800 |

360-540 |

133 |

GM1700-1100 |

1700 |

1100 |

2X1000 |

≤60 |

1100-1300 |

≤3 |

1600-1800 |

530-800 |

179 |

GM1700-1400 |

1700 |

1400 |

2X1250 |

≤60 |

1100-1300 |

≤3 |

1600-1800 |

670-1000 |

208 |

Studded RollPlanetary ReducerCouplingPacking & Shipping

Studded RollPlanetary ReducerCouplingPacking & Shipping

Introduction:

Introduction: There has 50 sets of machinery and

equipments to manufacture standard or

customer tailored mining equipments.

The maximum lifting capacity of the

mechanical processing reaches 40T,

and the maximum lifting capacity of the

assembling reach 65T. The company

has a complete testing capacity and a

highly-efficient and complete product

quality inspection tracking system.Foreign Visitors

Foreign

Foreign customer to

visit the

factory and

talksTeam

It is the mining machinery integrated technical research institute with strong R & D strength, many years of basic research in the heavy machinery in commonCertifiacte

It is the mining machinery integrated technical research institute with strong R & D strength, many years of basic research in the heavy machinery in commonCertifiacte

Q1 Whychoose us ?

We have a professional rich experiences stuffs;

We have the largest factories and production capacity since 1986;

The ZHONGYUAN euqipment, worthy of your trust!

Q2Does the equipment have any special Advantages?

1.The application of high pressure grinding roll can improve the productivity of the powder grinding system by 20%-30%.Power consumption of grinding system can decrease by 25-50% compared with the traditional grinding method.

2.The machine is equipped with sealing cap for rollers which can control the harmful dust spread to create a better production environment.

3.The machine has following advantages such as compact structure, less space-occupation, high reliability. Its operation efficiency can be up to approx.95%.

4.It is lower energy-consumption, less pollution which is the energy conservation and emission reduction and environmental protection product.

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.Ultra-fine Crushing Machine HPGR for Magnesia ore grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,Ultra-fine Crushing Machine HPGR for Magnesia ore coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and Ultra-fine Crushing Machine HPGR for Magnesia ore thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.Ultra-fine Crushing Machine HPGR for Magnesia ore adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK