10t/h finely jaw crusher export to Korea

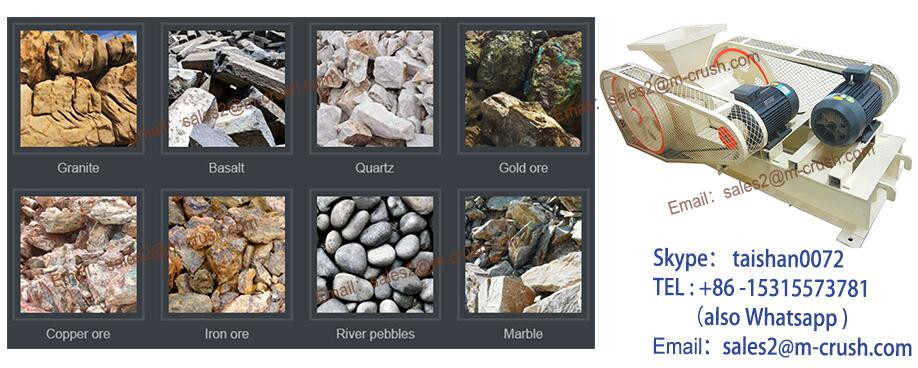

Kataic new generation jaw crusher, pew series jaw crusher is born with innovative significance. It is newly designed and improved by our experts on basis of their more than 20 years' crusher manufacturing and design experience. The unique design concept makes this series limestone jaw stone crusher achieve perfect combination between crushing efficiency and operating cost. Meanwhile, it has a wide range of application, particularly is suitable for crushing hard rock, such as basalt, river pebbles.

Finely jaw crusher Applications

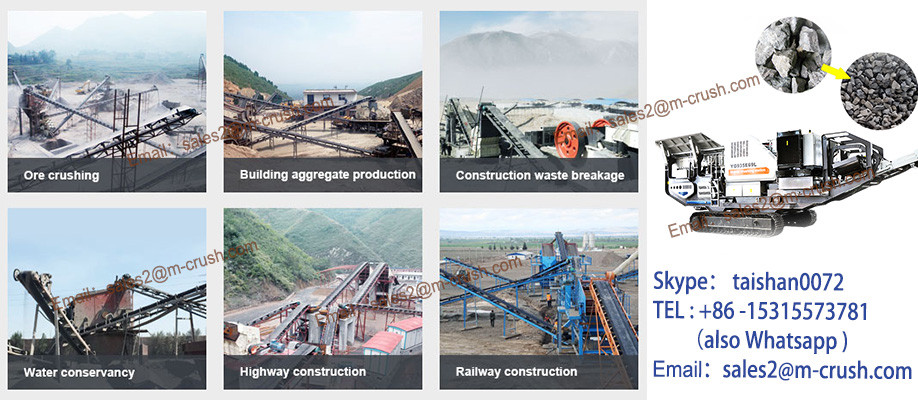

Jaw crusher is widely used for medium crushing various ores and bulk materials in mining, smelting, building materials, highway, railway, water, chemical industry and other industries. The crushed materials are of a compressive strength less than 320MPa. Jaw crusher has the characteristics of big crushing ratio, uniform finished product size, simple structure, reliable work, convenient repair and low operating costs.

Finely jaw crusher Working principle

The structure of jaw crusher: main frame, eccentric shaft, a large belt pulley, fly wheel, swing jaw, side guard plate, toggle plate, Rear bracket, adjust gap screw, reset spring, and fixed jaw and swing jaw board etc., and the toggle plate also plays a role of protection.

The motor transmits power through belt and belt pulley, drives the swing jaw surround the eccentric shaft do periodic motion. The angle between toggle plate and swing jaw increases when swing jaw moves up., which makes the moving jaw get closes to the fixed jaw.

At the same time the material is squeezed, rubbing, grinding and other multiple broken. The angle of Jaw Crusher between toggle plate and swing jaw decreases when swing jaw moves down, the moving jaw of Jaw Crusher moves away from fixed jaw by the pulling of rod and spring, the products after crushing will be discharged from the outlet of Jaw Crusher.

Finely jaw crusher Features

1, Simple structure and stable performance;

2, Deep crushing chamber and no dead zone can improve feeding capacity and output;

3, Big crushing ratio and uniform particle size;

4, Gasketed discharge opening adjustment device is reliable and convenient. large adjustment range can increase the flexibility of the equipment;

5, Reliable lubrication system, convenient spare part replacement and easy maintenance.

6,Energy-saving: the stand-alone can reduce the energy consumption by 15-30% while the whole system can save energy more than one times.

7, Low noise, less dust.

Finely jaw crusher for sand/stone making line:

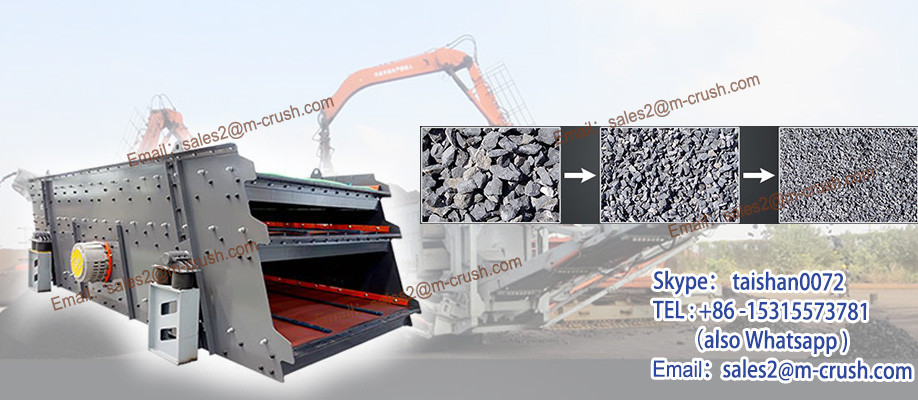

In the process of sand making production line, raw materials are conveyed to the jaw crusher for a coarse crushing by the belt conveyor; after the rough crushing, the materials are conveyed into a fine jaw crusher for a further crushing, then the fine crushed materials are conveyed into the vibrating screen for a separation which classified the materials into two kinds of stone, one part that meet the size of feeding mechanism of sand gravel base sand will feed into the sand making machine, another part will feed back again into the fine jaw crusher for a third crushing, the size of fineness can be adjusted according to customer demand. Fine jaw crusher are the improved simple pendulum or compound pendulum jaw crusher, which applys a plurality of the dynamic jaws and a plurality of eccentric shaft structures, which will reduce the loads of the machine when the jaw crusher running. And it is easy to start, smooth to run and with low energy consumption.

With larger feed openings and bigger crushing strokes, the Jaw Crusher is suitable for crushing big size lumps in large quantity.From the welded steel base to the rugged eccentric shaft, the jaw crusher is built with brute strength with quality bearings. Stone jaw crusher is one of the main types of secondary crushers in a mine or ore processing plant.

Finely jaw crusher Technical Parameters:

| Type | Feed Opening(mm) | Max.feeding size(mm) | Adjusting range of discharge opening(mm) | Capacity | Motor power | Total weight | Dimensions(L*W*H) |

| (t/h) | (kw) | (t) | (mm) | ||||

| PE250×400 | 400×250 | 200 | 20-50 | 41779 | 15 | 3 | 1430×1310×1340 |

| PE400×600 | 400×600 | 350 | 40-100 | 15-60 | 30-37 | 7 | 1700×1732×1653 |

| PE500×750 | 500×750 | 425 | 50-100 | 40-110 | 45-55 | 12 | 2035×1921×2000 |

| PE600×900 | 600×900 | 480 | 65-160 | 90-180 | 55-75 | 17 | 2290×2206×2370 |

| PE750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 90-110 | 29 | 2655×2302×3110 |

| PE900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 110-132 | 58 | 3800×3166×3045 |

| PE1000×1200 | 1000×1200 | 850 | 200-300 | 280-560 | 110-160 | 69 | 5350×4280×3050 |

| PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 6380×5310×3710 |

| PE1500×1800 | 1500×1800 | 1200 | 210-360 | 520-1100 | 280 | 132 | 7460×6235×4249 |

| PEX150×250 | 150×250 | 125 | 10-40 | 1-3 | 5.5 | 1.5 | 896×745×935 |

| PEX150×750 | 150×750 | 125 | 18-48 | 5-16 | 15 | 3.8 | 1200×1500×1200 |

| PEX250×750 | 250×750 | 210 | 25-60 | 15-30 | 22-30 | 5 | 1667×1545×1020 |

| PEX250×1000 | 250×1000 | 210 | 25-60 | 15-50 | 30-37 | 7 | 1550×1964×1380 |

| PEX250×1200 | 250×1200 | 210 | 25-60 | 20-60 | 37-45 | 8.5 | 2192×1900×1950 |

| PEX300×1300 | 300×1300 | 250 | 20-90 | 30-90 | 55-75 | 11.5 | 1750×2320×1724 |

Any change of technical data shall not be advised additionally.

Packaging & Shipping

Certifications

Our Services

Service and Solutions Pre-sale services: We can provide you with project design, process design, suitable purchase program for your equipment.Also design and manufacture products based on your specific needs, to train your technical personnel.

Sale: We will accompany you to complete the equipment inspection, construction plan and assist in the development process in detail.After Sale Service: We send technicians to the scene to guide the equipment installation, commissioning and training your operating personnel. Company Information

Zhengzhou 10t/h finely jaw crusher export to Korea Co., Ltd. is a large-scale joint-stock enterprise, focas on the production of heavy mining machinery, integrated with scientific research, production and sales. The company is located in zhengzhou national hi-tech industrial development zone, covers an area of 50,000 square meters, with 15,000 square meters two standardized heavy industrial plant, more than 160 sets all kinds of large and medium sized metal processing, welding, assembly equipment.

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.10t/h finely jaw crusher export to Korea grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,10t/h finely jaw crusher export to Korea coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and 10t/h finely jaw crusher export to Korea thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.10t/h finely jaw crusher export to Korea adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK