Product Description

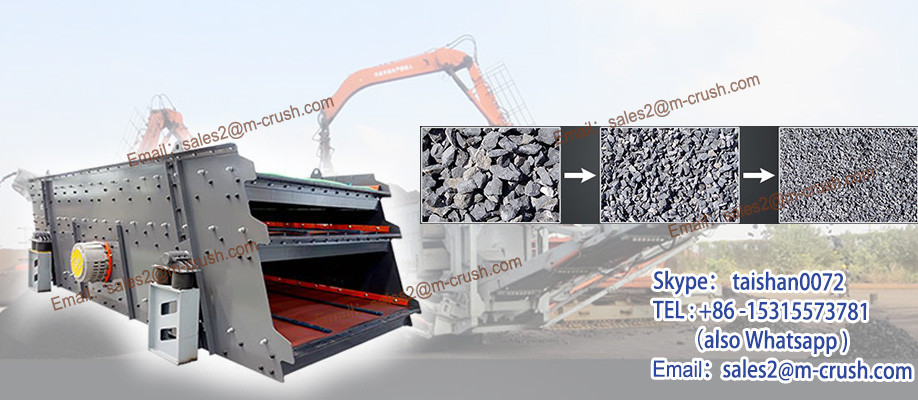

Product Application

ATAIRAC HPY series mutil-cylinder cone crusher developed and manufactured by our company is currently the most advanced cone crusher in whole China. It aims at the high end market and is integrated with the advanced mechanical, electrical and hydraulic technologies as a whole, which achieves the perfect crushing efficiency. HPY cone crusher features in robust casting steel frame, forged alloy main shaft, and high accurate gear transmission system. Combined with one suitable crushing chamber from all optionals and PLC automatic control system, the HPY cone crusher could fully play its performance and advantages. It is widely used for the fine and coarse crushing of various kind of stones and minerals, which features in high crushing efficiency, and could meets different crushing requirement for our clients.

Main Features

1) High production efficiency

Scientifically design of crushing chamber, large eccentricity, high swing frequency, lamination crushing and hydraulic controlled constant crushing force ensures more stable operation, bigger passing capacity, higher production efficiency and better products shape, as well as reducing the power consumption to the least.2) High automation PLC automatic control system can realize the functions of overload protection, tramp iron protection, discharge opening adjustment, chamber cleaning, as well as monitor oil temperature, pressure and flow, machine loading, discharge opening size, etc. so as to ensure the stable running of the machine.

3) High load capacity

Enhanced main frame and high-strength fixed shaft, hydrodynamic lubrication designed copper sleeve, as well as sensitive and reliable overload protection system ensues the long and smooth running of the machine even in extremely harsh working condition.4) Wide adaptability

HPY cone crusher has two types: standard head and short head. Each type has various kinds of optional crushing chambers. By replacing liners, belt wheel, auxiliary ring, and some other parts, it could realize the transformation of the two big series, which aims to adapt different processing flow and working condition. By adjusting the rotational speed of transmission shaft, it could adjust the grading of finished products, so as to maximum the machine’s value.5) Low running noise and vibration

High accuracy of spur gear and bevel gear transmission structure features in lower running noise, higher transmission efficiency, and durable in use. Lower vibration of main machine itself and flexible supporting with overall steel frame minimize the vibration to the least, so as to reduce the cost of foundation.6) Lower installation cost

HPY cone crusher is born with the advantage of lower installation height, which could largely reduce the labor cost. Besides, the overall steel base frame makes the installation more easy and time-saving to reduce the cost.

7) Lower operation cost Special designed crushing chamber, mantle, bowl liners and material ensures higher utilization ratio and durable of liners. Most parts can be assembled and disassembled on the upper and lateral side, which makes the machine maintenance more labor-saving and time-saving.

Strucure

Detailed Images

Detailed Images

Crushing Chamber Selection

| Model | Crushing Chamber | Standard | Short Head Type | ||

| Min.setting (mm)A | Feed opening (mm)B | Min.setting (mm)A | Feed opening (mm)B | ||

| HPY300 | EF | |

|

6 | 25 |

| F | 13 | 107 | 6 | 25 | |

| M | 16 | 150 | 8 | 53 | |

| C | 20 | 211 | 10 | 77 | |

| EC | 25 | 233 | |

|

|

| HPY400 | |

|

|

6 | 30 |

| F | 14 | 111 | 6 | 40 | |

| M | 20 | 198 | 8 | 52 | |

| C | 25 | 252 | 10 | 92 | |

| EC | 30 | 299 | |

|

|

| HPY500 | |

|

|

6 | 35 |

| F | 16 | 133 | 8 | 40 | |

| M | 20 | 204 | 10 | 57 | |

| C | 25 | 286 | 13 | 95 | |

| EC | 30 | 335 | |

|

|

| HPY800 | F | 16 | 219 | 5 | 33 |

| M | 25 | 267 | 10 | 92 | |

| C | 32 | 297 | 13 | 155 | |

| EC | 32 | 353 | |

|

|

Every model of HPY series products has five cavity type options: EF(extra fine), F(fine), M(Medium), C(Coarse), EC(Extra Coarse).

1.Min. setting means the minimum discharge opening size which could be setted without causing the adjusting ring to bounce. It may changed as the raw material and working condition becomes different.

2.“A” is the corresponding feeding opening of closed side of the min. setting “B”.

3.The max. feeding size will range from 80% to 100% according to the different model and raw material.

Main Spare Part

Our Company ATAIRAC is a Sino-French cooperation enterprise. By technically cooperating with the French company ALTAIRAC with a business history over hundred years, ATAIRAC engages in further research&development, manufacture and sale of crushing equipment(Jaw crusher, cone crusher, impact crusher, vsi, feeder, vibrating screen, sand washer, ball mill, grinder, etc). At present:

ATAIRAC production base:over 300000 square meters

Pre-sale service engineers: 20

Process engineers:102

Design engineers: 65

Production engineers: 500

After sales service engineers: 60

Production ability: 100000 tons/ year of crushing equipment

ATAIRAC equipment is widely used in the fields of mining industry, cement industry, concrete and aggregate, refractory industry, chemical industry, etc.

Our Service

Our Service

ATAIRAC company have 60 after sales service engineers. According to customer needs can go abroad for service.Packing & Delivery

ATAIRAC company have 60 after sales service engineers. According to customer needs can go abroad for service.Packing & Delivery

| Packaging | |

| Size | main machine 3000 (L) * 2300(W) * 2300(D) |

| Weight | pending |

| Packaging Details |

1. The small parts package is wooden box.2. The main machine nude packing, container, or upon customers requirement. If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

FAQ

FAQ1. Can you give me a solution and quotation?

Answer: Of course. Kindly please tell us information such as, the capacity? (100t/h, 150t/h, 200t/h......) the raw material ?(limestone, pyrite, granite, basalt......) hardness?(soft stone or hard stone……) maximum feed size ?(300mm,400mm,500mm......) output size ? (0-5mm,5-8mm,8-15mm,15-25mm......) the usage of final products ? (for railway, road construction, building......) We will provide the best solution and quotation.

2. How about the shape of aggregate manufactured by your company’s crusher?

Answer: The shape of aggregate has something to do with design of crusher. The shape also has something to do with design of complete stone production line. Our engineers will design complete stone production line based on raw material. The shape of aggregate will be cube which is better compared to other companies.

3. How long is date of delivery ?

Answer: The date of delivery is about 30~45 days. The date of delivery will be extended if the stone production line is too big or the clients have some special requirement.

4. How long is the guarantee period of your company’s crusher?

Answer: The guarantee period of our company’s equipment is 13 months. Wear resistance parts and problem coursed by worker’s unsuitable operation are not included.

5. What’s the after sale service of your company?

Answer: The construction drawings of foundation will be supplied for our clients. What’s more, we will supply installation service, workers training service, etc.

6. Can you supply wear resistance parts for us if we buy your company’s products?

Answer: Of course we can supply. We have two our own casting factories and We can supply enough wear resistance parts for our clients in order to guarantee machine operation.

7. Can your company’s equipment be used in harsh environment like colder than -10℃ or hotter than 50℃?

Answer: Of course. Our equipment adopts XYZ-G lubrication and temperature control system.

Welcome to contact Yilia Yang.

Impact Crusher PFS

91.8% Response Rate

Cone Crusher GPY

91.8% Response Rate

Sand making machine

91.8% Response Rate

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.China stone Hydraulic Cone Crusher price of ATAIRAC HPY800 grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,China stone Hydraulic Cone Crusher price of ATAIRAC HPY800 coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and China stone Hydraulic Cone Crusher price of ATAIRAC HPY800 thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.China stone Hydraulic Cone Crusher price of ATAIRAC HPY800 adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK