Lead ore impact crusher

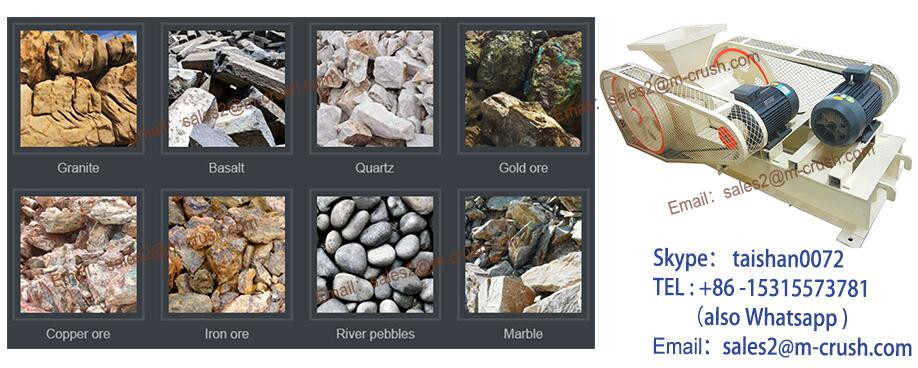

Impact crusher is widely used in high road construction, water conservancy and construction process of gravel and so on. This series of Impact Crusher are optimized after adopting advanced techniques. It’s widely applied in mining, energy, transportation, construction and chemical industry and mainly used to crush many kinds of large, medium, small sized materials with compression resistance no more than 350Mpa, in the fields of highway, reservoir, railway, airport and other fields that need rock with cubic shape. It can crush granite, basalt, bluestone, etc the diameters of which are from 100mm to 500mm, and its crushing compression strength is not more than 320Mp. They are ideal choice for crushing and screening.

Working Principle

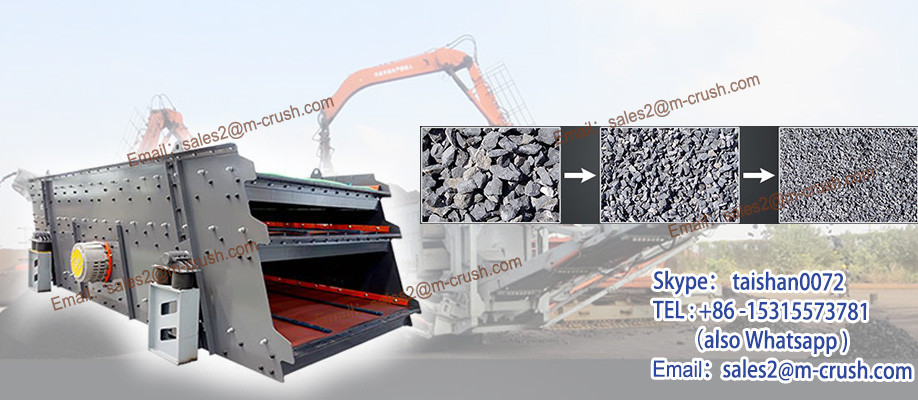

The materials are crushed via impact energy produced in the impact crusher. When the fine impact crusher works, with the help of the motor, the fine impact crusher’s rotor rotates fast, the material is crushed by the shock of rotor’s hammer in the first crushing zone, and being crushed in the second fine crushing zone, then discharged from the output.

Impact crusher is the machine which breaks materials using the impact energy. The rotor rotates with a high speed driven by power motor when the machine is working. When the materials get into hammer effect area, they are impacted to break on the rotor and then thrown to the impacting position to take another crushing. After that materials will spring back to hammer impacting area from impact wrist plate for crushing again. When the materials are crushed to the required size, they will be discharged from the outlet. The material's discharging size and shape can be changed through adjusting the gap between impact frame and rotator.

Advantage & Features

1. Simple structure, small size, light weight, high production capacity, low production cost.

2. Non-key Connection, high chromium plate hammer, hydraulic or manual open, unique back liner.

3. High crushing ratio, so that it is able to simplify the crushing process and changes the three-stage crushing into two-stage or single-stage crushing and reduces the cost of the ore beneficiation plants.

4. The gap between the impacting plate and the hammer plate can be conveniently changes, thus effectively adjusting the discharging granularity.

5.Hard rock crushing, energy efficient.

6. Comprehensive crushing functions, high production rate and comprehensive interests.

Technical Parameter

| Model | Specification (mm) |

Feed opening (mm) |

The Maximum Feeding Size (mm) |

Capacity (t/h) |

Power (kw) |

Total weight (t) |

Overall dimension (L×W×H) (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 37-45 | 12 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 45-55 | 15 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 110 | 17.7 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 100-180 | 132 | 22.4 | 2650×2460×2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 130-250 | 220 | 27 | 3180×2720×2620 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 300-550 | 315-400 | 50.6 | 3959×3564×3330 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 600-800 | 630-710 | 83.21 | 4400×3866×4009 |

Company Information

Henan Fote Heavy Machinery Co., Ltd., the former Henan First Machinery Factory, founded in Henan

Zhengzhou China machinery manufacturing capital in 1982, is a large jointstock company specialized

in manufacturing heavy mining machinery and civilian machinery; it has six production bases with an

area of 240,000m2, more than 2000 existing employees, 160,000 m2 tandardized heavy industrialplant, and about 500 sets of big and medium sized processing, riveting, welding and assembly equipment. After 30year construction and development, Fote has become famous production and export base of mining machinery and civilian machinery in China.We provide series of ore-dressing plant,sandstone equipment,ball mill,industrial dryer,ungrouped,confeyor system,magnetic separator,flotation machine,gravity separating machines,high frequency screen,rotary kiln, ect. Our products have been sold to more than 90 countries and regions all over the world, such as Russia, the United States, Kazakhstan, India, Indonesia, South Africa, Libya, Sudan, Iran and so on.

Our Services

1, We will provide you the prophase plan, process flow design and manufacturer equipment according to your special requests.

2, We will send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

3, We will regularly pay return visit to customers to establish long term friendship. Supplying technique, building design, instruction, installation and debugging for free.

4, We provide one-year warranty to make sure your machine runs consistently. We are always offering lifelong services and provide spare parts for a long term, and repair main parts under right using for free in two years.

FAQ

1.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2.Guaranteed:

If products’quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Yes, we are factory and be able to give you the lowest price than market one, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

4.Service and Payment Terms?

A. We usually accept T/T, L/C;

B. T/T: 30% in advance as down payment, the balance before delivery;

C. We take pictures of finished products before delivery.

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.Lead ore impact crusher grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,Lead ore impact crusher coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and Lead ore impact crusher thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.Lead ore impact crusher adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK