Hot sale high quality fine roller crusher

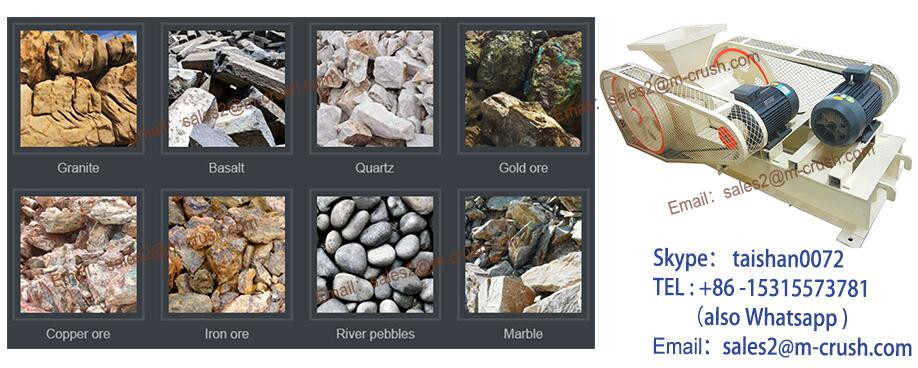

The double rollers crusher is widely used for secondary and fine crushing in the industry of mining, building materials, chemical industry, metallurgy and so on. It can crush materials in middle hardness such as rocks, ore, coke, lump coal, slag, mineral slag, cement clinker, fireproof materials, and so on.

Working principle of fine roller crusher:

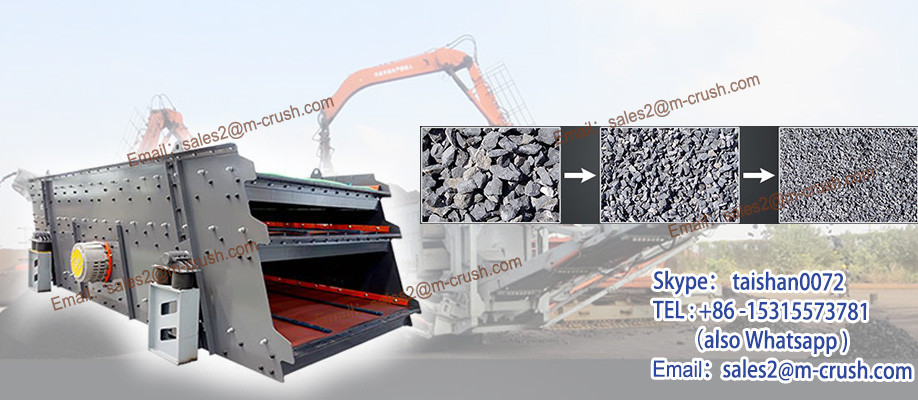

Big size stones are transferred to primary crusher through vibrating feeder from hopper for first crushing, then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing. The materials crushed will be transferred to the vibrating screen, and separated to different sizes. The aggregate with suitable size will be transferred to the final product pile and aggregate with unsuitable size will be transferred to the impact crusher for re-crushing. This forms a closed and manifold cycles. The sizes of final products will be graded and separated according to customers' requirements, and the duster will be attached for the sake of environment protection.

Features of fine roller crusher:

1. Their initial cost is lower

2.They are durable and strong

3.Design is simpler and easier to repair

4. Taking electric and torque converter double overload protection to improve its reliability and safety.

5. Fixed spacing between 2 tooth rollers makes it stable to discharge.

6. Using PLC to control the whole procedure, increase its automation level.

7. All tooth roller bearings are lubricated concentrated with lubricating grease pump, more convenient and faster.

8. Reasonable design for the shape of tooth plate and high-qualified wear resistant material extents its working life.

The main technical data of fine roller crusher:

Type |

Model |

Feed Size (mm) |

Output size (mm) |

capacity (t/h) |

power (KW) |

Dimension(L×W×H)(mm) |

Weight(Kg) |

|

Double Roller |

2PG250×400 |

2-8 |

1.5~7 |

2×5.5 |

1430×1481×816 |

1200 |

|

2PG610×400 |

2~9 |

3~9 |

2×11 |

1785×2365×1415 |

3800 |

||

2PG750×500 |

2~10 |

7~12 |

2×15 |

2720×2700×1400 |

10250 |

||

2PG750×700 |

5~10 |

15~25 |

2×22 |

3422×2800×1705 |

11700 |

||

2PG750×1000 |

2~10 |

6~30 |

2×30 |

4150×2800×1750 |

12500 |

||

2PG900×500 |

2~10 |

9~30 |

2×22 |

2750×1790×2065 |

14000 |

||

2PG900×900 |

2~10 |

11~45 |

2×30 |

2750×2180×2065 |

16800 |

||

2PG900×1200 |

3~10 |

15~60 |

2×55 |

2750×2480×2065 |

20800 |

||

2PG1000×800 |

25~90 |

3~40 |

12~50 |

2×45 |

2940×2080×2065 |

22600 |

|

2PG1200×1000 |

3~12 |

10~50 |

2×37 |

3690×3430×2700 |

46820 |

||

2PG1200×1200 |

3~12 |

18~68 |

2×75 |

3690×3630×2700 |

48600 |

Your desire, we design. We are one of the most professional manufacturers of fine roller crusher.

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.Hot sale high quality fine roller crusher grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,Hot sale high quality fine roller crusher coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and Hot sale high quality fine roller crusher thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.Hot sale high quality fine roller crusher adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK