vsi series stone fine crusher

China Manufacturer of Jaw crusher, impact crusher, roller crusher, hammer crusher, vsi sand maker, fine sand making machine, cone crusher for stone crushing plant

Usually speaking, a complete stone crushing plant consists of vibrating feeder, coarse jaw crusher, fine jaw crusher, impact crusher or cone crusher, vibrating screen and belt coneyors, the coasre jaw crusher is used as the primary crushing purpose, fine jaw crusher, cone crusher and impact crusher are used for the secondary crushing purpose, the vibrating screen is used to sieve the crushed materials into the sizes required, such as 0-1mm, 1-3mm, 3- 5mm, 5-10mm, 10-15mm and so on. the belt conveyors are used to convey the materials among the equipments and transport the crushed materials to the designed sand/aggregate stocks. Zhengzhou Jiangtai Heavy Industrial Machinery Co., LTD can provide the complete crushing and screening plant according to your specific requirments, in order to provide a suitable solution for you at the earliest time, please inform the details as follows so that we can prepare a solution based on your requirements:

1: which stone do you want to crush, limestone, river stone, granite, copper ore, iron ore or the other?

2: its initial size

3: the finished sizes you want to get after crushing processing

4: how many tons do you want to crush per hour

Main Technial Parameters of VSI CRUSHER

Model |

VSI-7611 |

VSI-8518 |

VSI-9526 |

VSI-1140 |

||

Capacity |

Center and Sides Feeding |

120-180 |

200-260 |

300-380 |

450-520 |

|

Center Feeding |

60-90 |

100-130 |

150-190 |

225-260 |

||

Max. Feeding Size (mm) |

Soft Material |

35 |

40 |

45 |

50 |

|

Hard Material |

30 |

35 |

40 |

45 |

||

Rotation Speed(rpm) |

1700-1890 |

1520-1690 |

1360-1510 |

1180-1310 |

||

Double Motor Power (kw) |

110 |

180 |

264 |

400 |

||

Overall Dimension |

3700×2150×2100 |

4140×2280×2425 |

4560×2447×2778 |

5000×2700×3300 |

||

Weight (t) |

7.8 |

10.3 |

16 |

25.6 |

||

Vibration Sensor |

Inspection scope: 0.1-20mm/s continual adjustment |

|||||

Hydraulic oil pump |

Motor Power of Double Oil Pump(Kw) |

2×0.31kw |

||||

Overall Dimension |

820×520×1270 |

|||||

Power of Oil Tank Heater |

2KW |

|||||

Main Technical Parameters of roller crusher

| Model | 2PG400×250 | 2PG610×400 | 2PG700×400 | |

| Roller Diameter(mm) | 400 | 610 | 700 | |

| Roller Length(mm) | 250 | 400 | 400 | |

| Max. feeding size(mm) | ≤25 | ≤85 | ≤100 | |

| Discharging size(mm) | 2-8 | 0.5-30 | 0.5-30 | |

| Efficiency(t/h) | 5-10 | 13-40 | 10-100 | |

| Roller number | 2 | 2 | 2 | |

| Roller rotation speed(r/min) | 180 | 75 | 95 | |

| Total weight(t) | 2.2 | 5.9 | 9.8 | |

| Dimensions(L*W*H)(mm) | 1215×834×830 | 3700×1600×1100 | 4300×1200×1200 | |

| Motor | Power(kw) | 5.5×2 | 15×2 | 30×2 |

Main Technical Parameters of fine crusher

| Model |

Feeding size(mm) |

Discharging size(mm) |

Capacity(t/h) | Power(kw) | Weight(t) |

| PCX800×300 | ≤60 | ≤5(96%) | 20-25 | 37 | 2.5 |

| PCX800×600 | ≤60 | ≤5(94%) | 35-50 | 45 | 4.7 |

| PCX800×800 | ≤70 | ≤5(92%) | 40-60 | 75 | 6.5 |

| PCX1000×1000 | ≤80 | ≤5(91%) | 60-90 | 90 | 8.8 |

| PCX1000×1200 | ≤90 | ≤5(88%) | 75-110 | 110 | 13.6 |

| PCX1300×1200 | ≤100 | ≤5(86%) | 120-145 | 160 | 19.5 |

| PCX1300×1400 | ≤120 | ≤5(85%) | 145-180 | 180 | 26 |

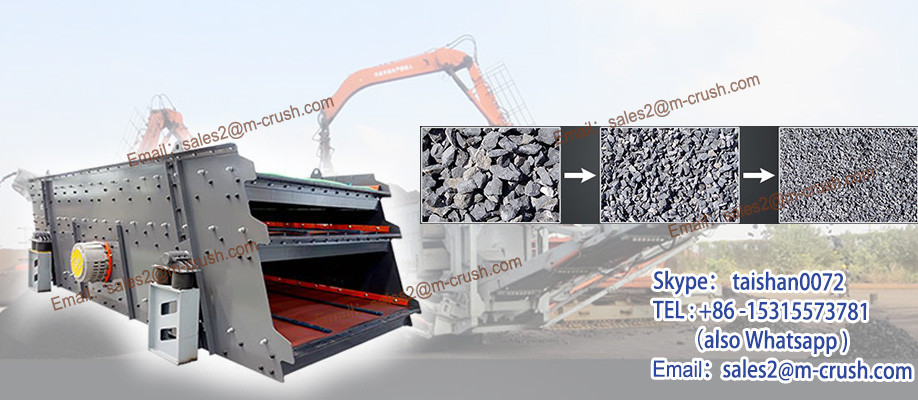

Main Technical Parameters of vibrating screen for sieving purpose

Main Features of crusher machine:

1. Roller bearings provide strength & safety. Oil bath lubrication ensures vsi series stone fine crusher service life.

2. Toggle plate, toggle block, and toggle seat protect the jaw crusher from damage caused by uncrushable material in the crushing chamber. This construction helps to maintain a stable crushing angle.

3. Simple & quick discharge gap adjustment, precise product grain distribution.

4. Large & deep crushing chamber with sharp crushing angle, to achieve a very high crushing ratio.

5. The Jaw Crusher with bigger feed opening and vsi series stone fine crusher pitman arm is especially suitable for primary crushing.

6. Recommended for big lumps & large quantities, for primary crushing of limestone, river stone, tough ores, and concrete recycling.

About the packing, for the equipment which are smaller than container, then we will transport the equipment with container loading, for those which are larger than containers, will be transported via bulk goods.

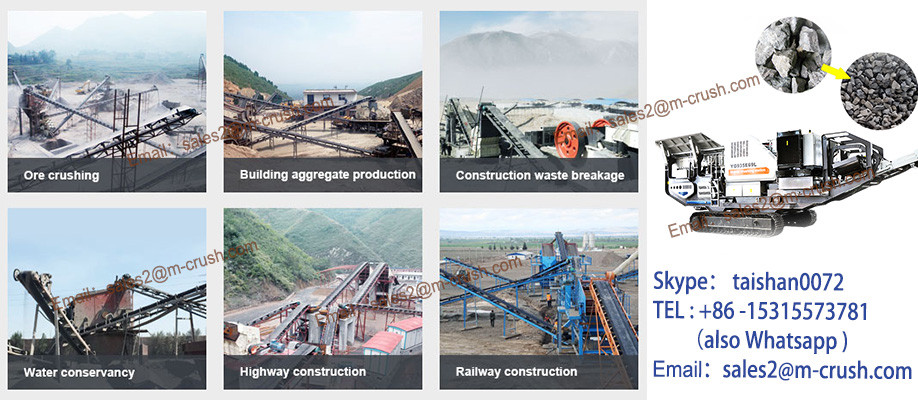

Application of the crusher

It is widely used for crushing of hard and brittle materials, such as rock, grinding material, refractory

material, cement clinker, quartz, iron ore, concrete aggregate & sand or aggregate making for

construction & road paving.

ABOUT US

Zhengzhou Jiangtai Heavy Industrial Machinery Co., LTD (JTHIM) is a heavy equipment factory in China, our main products includes jaw crusher, impact crusher, hammer crusher, cone crusher, ball mill, vibrating screen, sand washing machine, rotary dryer, magnetic separator, rotary kiln, cement ball mill and so on, which can be widely used in various industries, such as road and construction material production- sand and aggregate, cement production industry, ore beneficiation plant for various kinds of concentrates, for example, gold concentrate, zinc concentrate, copper concentrate, iron concentrate and so on, we will send our engineer to our clients' factory to guide the installation and commissioning, till the project can work normally, besides, our factory can provide one year warranty for the products we provided ( excluded the wear parts), Zhengzhou Jiangtai Heavy Industrial Machinery CO., LTD can be your trusted partner in China.

ServiceBefore sales, we sales team will know know the real situaiton from our customers, such as the feeding size, crushing capacity, final sizes and the electricity condition,etc. then our technician team will design proposals according the situations, and we will update the solution according to customer's further requirements.

After concluding the contract, our engineer technician will prepare the foundation drawing about the equipemnts. at the same time, our production factory will prepare the equipment timely.

After delivery, our installation engineer will be ready to guide the installation and commissioning for the equipment, to make sure that each item going smoothly and meet the customer's requirements.

FAQ

FAQ

01

Delivery time?

The lead time is 10-30 days, Delivery time will vary depending on the type of the machine, shipping method selected and

part availability.

02

Payment terms?

Accept Payment Type: T/T, L/C, Western Union, Cash

After sign the contract, pay the 10%-30% deposit of total purchase price and pay the full payment before delivery.

03

what will you do if the machine is broken down?

The Products warranty is one year. We will provide the technical advice and find the solution immediately for you when

the machine is in trouble. For those wear parts, we guarantee the high quality parts for long-term supply.

04

What should i do if I want to get a best quotation?

If you want a suitable type for you ,please let us know your material ,capacity, feeding size and final sizes you want after crushing.

05

Do you provide equipment operation training?

Yes. We can send technicians to the job-site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

06

Can you help chose suitable products?

Yes. We have many experts who have worked in this area for many years. They can help you select the most suitable products according to your actual condition. And they can design proper process flow a based on your special situation.If necessary, we can even send professionals to your local place for site planning and work-flow design.

Related Products

energy saving Spiral sand washer for stone, sand, rocks, ores

Industrial Wood Pellet Rotary Dryer Exporting With Ce Iso To India

china top brand iron ore vibrating screen

building material production plant/ artificial VSI sand making machine

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.vsi series stone fine crusher grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,vsi series stone fine crusher coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and vsi series stone fine crusher thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.vsi series stone fine crusher adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK