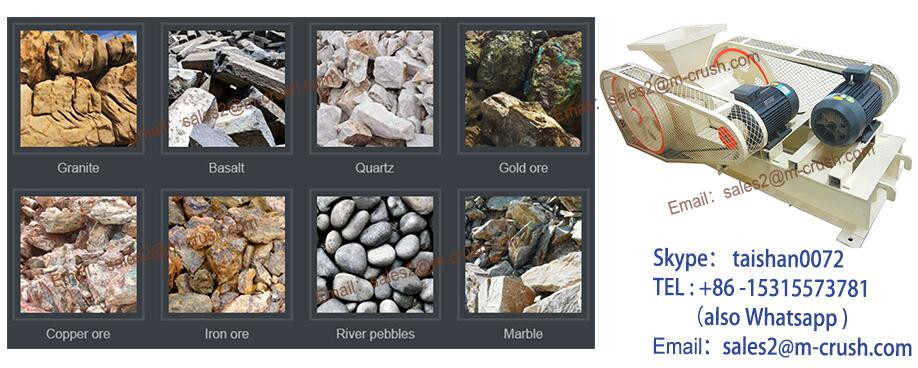

Product Photo

Rock crusher for sale introduction:

Rock crusher for sale is a common crushing equipment in sand-making production line and construction industry. Rock crusher for sale is used as sand maker in sand making industry and for super fine crushing in particular industry.

This series of rock crusher for sale is designed for crushing gangue specially.And when it is working,the noise is lower than the same type of crusher.In addition,we will provide you high quality crusher at best price,because we are manufacturer,not dealer,thus you can trust us.Therefore,you can save much investment,but can obtain same benefit.

Rock crusher for sale application:

Rock crusher for sale working principle:

After entering into the rock crusher for sale, the materials are attacked by the high speed hammers, and hit to the adjustable dental plate, to be primary crushed, the plate are located in the crusher entrance, and with super wear-resistance. Then the similar size entering into the main crushing cavity, to be secondary crushed.

After secondary crushing, the material are attacked by the hammers again, regain kinetic energy, highly hit to impact liner plate (toothed). The materials are crushed again and again, between the liner plate, the hammers, and the material themselves. Then the fine materials are discharged from discharge hole, being the final-products. The final size can be adjusted according to the space between rotor and the liner plate.

Rock crusher for sale Specifications:

| Specifications | ||||||||

Model |

Rotor size |

Max feeding size |

Discharge size(mm) |

Capacity(t/h) |

Power(kw) |

Weight |

||

| PCK0808 | 800*800 | 80 |

6 (99%) 3(90%) |

25-40 | 90 | 4.9 | ||

| PCK1010 | 1000*1000 | 35-70 | 90-135 | 9.8 | ||||

| PCK1012 | 1000*1250 | 70-90 | 132-160 | 14 | ||||

| PCK1212 | 1250*1250 | 100-120 | 160-220 | 19.8 | ||||

| PCK1215 | 1250*1500 | 120-150 | 220-380 | 22 | ||||

| PCK1415 | 1400*1500 | 160-250 | 280-380 | 26.5 | ||||

| PCK1418 | 1400*1750 | 250-300 | 380-550 | 33 | ||||

The capacity refers to limestone, professing capacity may vary with different materials and feeding size. | ||||||||

Rock crusher for sale features:

1. Large crushing ratio, high crushing efficiency.

2. Even producing granularity, overgrind is less.

3. Simple structure, stable performance, convenient to maintenance.

4. Good wear resistance, and low energy consumption.

Company Information

We offer you the early planing of the project,the best process flow design,choose the best appropriate equipment model to design products according to your special needs.

Sale: Integrity

All productds have to pass strict inspection with the drawings and process flow according to the contract before they go out. We assigned the technicians to the producing spot to provide installation guide, testing and training.

After-sale:Considerate

To establish good business relationship,we adopt periodical visit to the users.We could give you the definite reply during 24 hours when the users meet some problems in the producing process.

Attention

1,Crusher must be started without load.

2,The machine should be installed under shelter from rain and mustn't be put in the open air directly.

3,Electric motor should be installed in the rear of the crusher and the direction of rotation should be consistent with the crusher. Reverse is forbidden.

4,For the convenient transportation of the crude material , inputing or outputing materials had better use mechanized transport equipment.

5,Before debugging the equipment, we should tighten the screws and connect parts and check the lubrication conditions.

6,Feeding must be stopped before stopping the machine. Only all the material have been broken is spit out entirely, stopping working is available.

2. The Capacity, how many Tons Per Hour?

3. The stone type, iron, granite, limestone, or others.

4. Final output sizes, such as 0-5mm, 5-15mm, 15-25mm; or others.

5. The Voltage and Hertz, such as 380V, 50Hz or others. Customized Design is accepted.

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.wear-resistance stone reversible impact hammer crusher used in mining grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,wear-resistance stone reversible impact hammer crusher used in mining coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and wear-resistance stone reversible impact hammer crusher used in mining thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.wear-resistance stone reversible impact hammer crusher used in mining adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK