Fine output size roller mill, limestone crusher size reduction of coal, limestone, cement, rock

1. Limestone crusher application:

This limestone crusher can be applied in the industries of cement, the chemical industry, mining, metallurgy and building material, which is suitable for the medium crushing on the material. And the discharging granularity can be adjusted freely, so we must have one process of iron cleaning before the crushing process, because the hard iron material will bring much more damage to the crushing machine.

limestone roll crusher for lab is one mining machine which can be often seen in the mining sites, which is mainly used for crushing the materials such as the pebbles, quartz and ceramics, coal fines, coke breeze or gypsum waste, smashing or flattening pebbles or plastic lumps to produce thin, flat discs, strips. secondary reduction of coal, washed coal, middlings, screenings, slag, limestone, cement, rock, sulfur, and whose another name is roller mill.

2. LYTO limestone roll crusher features:

- High durable rollers, Fine output size roller mill, limestone crusher size reduction of coal, limestone, cement, rock service life.

- Fine output size.

- Fine and even output size, and no blocking for the roller.

- Stable working performance, easy to maintenance and inspection.

- Eco-friendly design, and easy to clean.

- high capacity, lower power consumption.

- Can work normally without fixing any base.

- Full sealed, environmental friendly.

- low noise and vibration. This provides a better work environment than jaw or impact style crushers. High efficiency crushing performance.

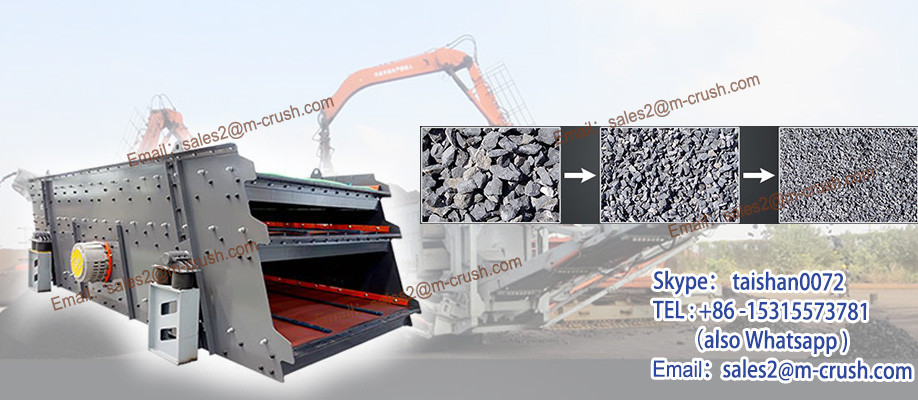

3. Working principle of limestone roll crushers:

This limestone roll crusher for lab is driven by the motor, the main shaft roller set revolving by the driving power of vee belt driving device. The main roller set and the sub roller set revolving relatively through the chain wheel, which makes the material crushed by the action of the extruding.

4. Main Structure of our limestone roll crushers:

Lab limestone roll crushers are composed by motor, vee belt rotating device, base frame, and cover hood,. The motor is three-phase asynchronous motor, and the vee belt rotating device are included by belt pulley, vee belt, and belt tension devices. The crusher devices are composed by main shaft roller set, subshaft roller set, chain wheel, chain, chain tension devices and the particle size adjusting devices.

5. Main Parameters of LT-200X150 limestone crusher for lab:

Model |

LT-200X150 |

Roller size |

200x150mm |

Feeding size |

less than 13mm |

Output size |

0.1-3mm |

| Capacity | 600kg/h |

| Motor power | 3kw |

| Dimension | 700x710x900mm |

| Power supply | 380v |

Packaging & Shipping

6. Packing ways: Standard export packing with plywood case

Export port: Guangzhou or Shanghai or as required

Delivery ways: by sea or air or express

Delivery time; about 10-15 days

Our Services

7. Warranty; 12 months

Before sales: Technical staff provide individual solution according to client process requirement

After sales: experienced after sales man follow the using condition, and solve any problem at the first time for you.

Engineer overseas were also available

8. More types of lab limestone crushers:

DISC MILLS WITH FINE OUTPUT SIZE

Ball mills with 0.074mm output size

LYTO TECHNOLOGY WOULD BE YOUR RELIABLE FACTORY.

LYTO---20 YEARS MANUFACTURE EXPRIENCE, WELCOME YOU TO CONTACT US FOR MORE DETAILS.

Lyto Factory manufacture the following lab equipment: Lab jaw crusher/lab grinding mill/lab roll crusher/ lab hammer crusher/lab flotation cell/ lab divider/lab shaking table/sieve shaker/ lab ball mill/ laboratory diaphragm Jig /riffle divider/ tungsten carbide jaw plate/ tungsten carbide grinding bowl ect

mill, laboratory diaphragm Jig ect!

CONTACT US AT:

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.Fine output size roller mill, limestone crusher size reduction of coal, limestone, cement, rock grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,Fine output size roller mill, limestone crusher size reduction of coal, limestone, cement, rock coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and Fine output size roller mill, limestone crusher size reduction of coal, limestone, cement, rock thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.Fine output size roller mill, limestone crusher size reduction of coal, limestone, cement, rock adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK