High Quality Electric Fine Crushing Double Rollers Crusher On Sale

we are factory,contact us by tel:High Quality Electric Fine Crushing Double Rollers Crusher On Sale56751333,Jennifer

We have 21 years working experience on mining machinery,Those experience makes us have the ability to produce the products you need.We really appreciate can be part of your business to help you in your local market.Welcome to our manufactory for inspecting and cooperation.

Specifications

1.Feeding Size:

2.Discharging Size:0.5-30mm

3.5-20 days delivery

4.ISO,CE

Product Description

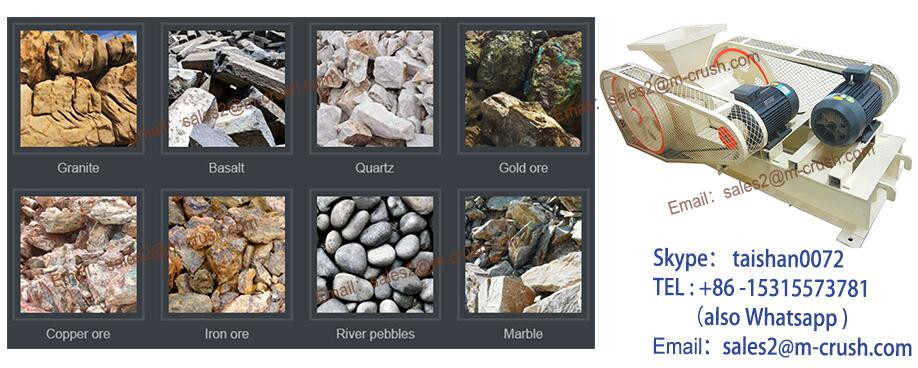

♥ The roll crusher, also known as roller crusher, teeth roll crusher or double roll crusher, is used to do medium and fine crushing of hard and medium hard ores and stones in the industries of ore beneficiation, chemical, cement, refractory matter, grinding materials, building materials.

♥ Usually, these crushers will have teeth or raised forms on the face of the roll. Roll crushers used for minerals and metal ores have smooth faced rolls.

Advantages

• They give a very fine product size distribution and produce very little dust or fines.

• Effectively used in minerals crushing where the ores are not too abrasive,also used in smaller scale production mining of more abrasive metal ores, such as gold.

• Coal is probably the largest user of roll crushers currently. Coal plants will use roll crushers, either single roll or double roll, as primary crushers.

Working principle

• The roll crusher is compression type crusher, and it is made up of roller, bearing , adjusting device and driving device etc.

The fixed part of roller and movable roller are driven by the motor via reducer and v-belt,the raw materials fall into the part between the two rollers from inlet of the machine.

• The two rollers rotates inward simultaneously.The materials are extruded, crushed and ground, then the end products come out from the bottom of this crusher.

Roller crusher Performance Parameters

Packaging&Shipping

Successful Case

50-100TPH Roller Crusher In India

2PGC 1000*1000 Roller Crusher

Max Feeding Size:300mm

Motor Power:2*15Kw

Shaft Speed:155r/min

Weight :15t

Our Service

♣ 24 hours online customer service, detailed and professional solution.

♣ Skilled engineers, scene investigation, free customized program solution.

♣ The purchase contract has a certain reputation guarantee, provide you the perfect product to your hands.

♣ After-sales service support, Expert technical training and operating instructions, site installation and commissioning, adhere to test equipment and visit our customers regularly.

♣ We offer all kinds of models, high-quality crushing and screening equipment parts.

Why Choose Us

♣ We are manufacturer of 21 years experiences, not dealer.

♣ We devote to create the biggest value with least cost for customers.

♣ We have a professional team to ensure your best pre-sale service, sale-service and after-sale service.

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.High Quality Electric Fine Crushing Double Rollers Crusher On Sale grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,High Quality Electric Fine Crushing Double Rollers Crusher On Sale coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and High Quality Electric Fine Crushing Double Rollers Crusher On Sale thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.High Quality Electric Fine Crushing Double Rollers Crusher On Sale adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK