new design 50% discount Fine Jaw Crusher, Secondary Jaw Crusher, Stone Crusher Machine

The Stone Crushing Plant

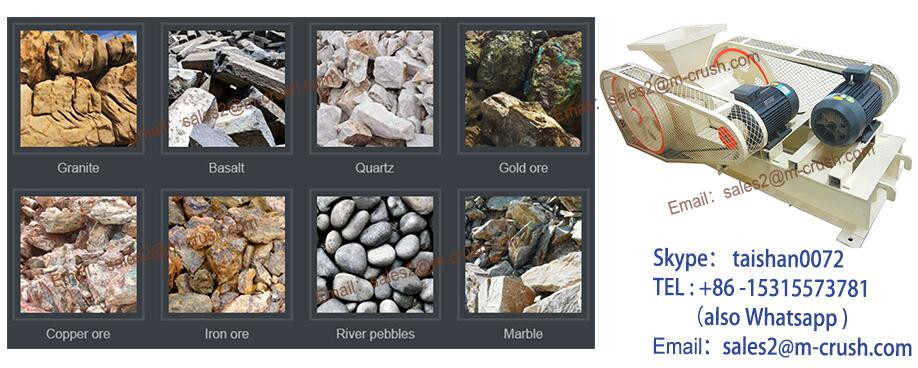

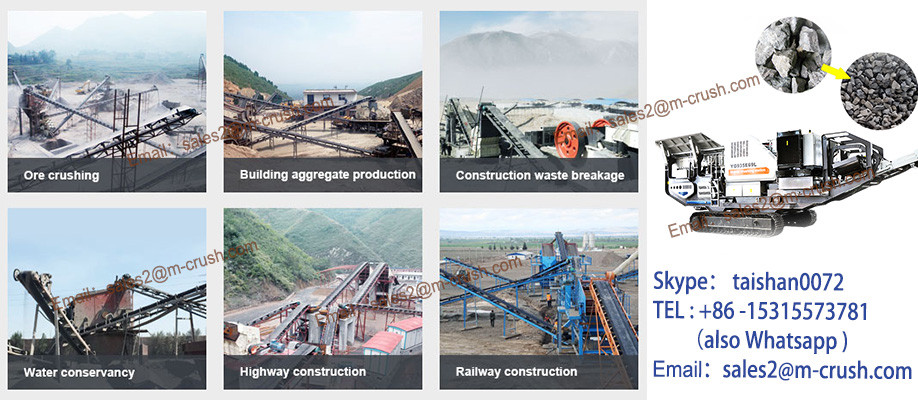

The Stone Crushing Plant mainly consists of Vibrating Feeder, Jaw Crusher, Cone Crusher or Impact Crusher, Vibrating Screen, Belt Conveyor and Control System, etc. It is completely capable to crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials, and produce sand & gravels with various granularities for construction and building industry. We are able to design and manufacture complete crusher plants with capacity from 30tph to 500tph, and to provide optimum and most economical solutions according to customers' requirements on stone specifications, output, application, etc.

Working Principle of the Stone Crushing Plant

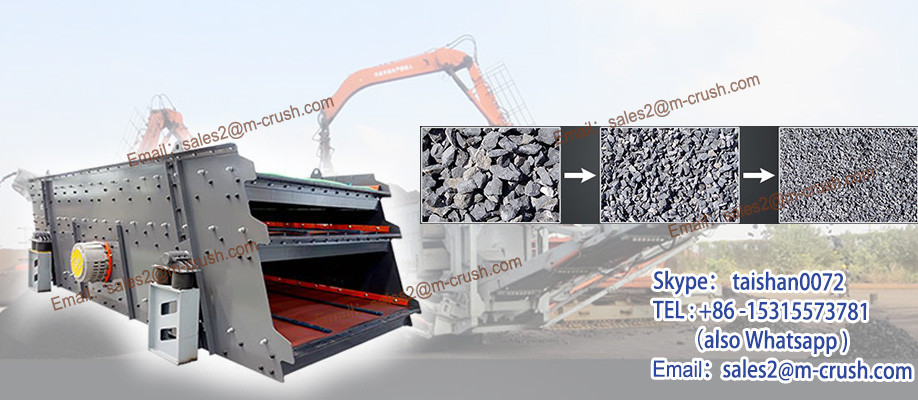

Large stone materials from the storage hopper are evenly and continuously fed into jaw crusher through vibrating feeder for primary crushing; the crushed materials are transported to cone crusher or impact crusher for fine crushing through belt conveyor; then the materials are transported to vibrating screen to be separated into different sizes. The end products with desired sizes will be transported to the final product pile and those with big sizes will return to the cone crusher or impact crusher for re-crushing. This forms closed and continuously automatic cycles. The plant can be equipped with dust removing facilities to protect environment according to customers' requests.

Features and Advantages of the Stone Crushing Plant

1.High degree of automatic operation; the entire production line requires almost no manual operation except for machine starting and stopping, routine maintenance.

2. High productivity, low investment, and good appreciation.

3. Regular end product granularity, good grain shape, and low powder output.

4. Adopting high advanced control system to ensure security and reliable operation of the entire production line.

The Detailed Parameters of the Stone Crushing Plant

Product show case:

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.new design 50% discount Fine Jaw Crusher, Secondary Jaw Crusher, Stone Crusher Machine grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,new design 50% discount Fine Jaw Crusher, Secondary Jaw Crusher, Stone Crusher Machine coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and new design 50% discount Fine Jaw Crusher, Secondary Jaw Crusher, Stone Crusher Machine thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.new design 50% discount Fine Jaw Crusher, Secondary Jaw Crusher, Stone Crusher Machine adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK