Specifications

jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher

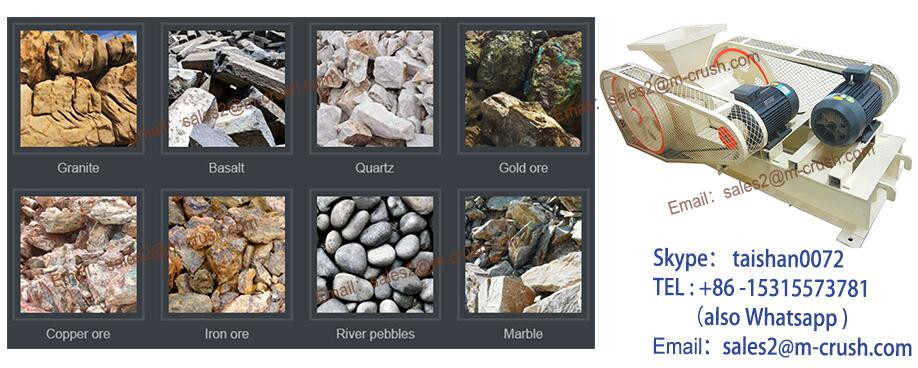

1. crushing materials including granite,basalt,limestone,river stone,sandstone,shale,iron ore,copper ore,etc

2. capacity: 2-800TPH

3. Max Feeding: 1020mm

What is the dream of the shanghai shibang machinery Co.,Ltd?

A better world, to help customers achieve maximum benefits are the dreams

We've been trying so hard for

Sunshine, flowers, spring colors the earth to green.

Customer's satisfied jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher

We keep trying

More professional

More environmentally friendlyProduct Description

jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher introduction:

jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher---

Jaw crusher becomes the most welcome products in the world. When you want to crush the hard materials in high efficiency, the best choice for you is the China SBM crusher in European style, which adopts the most advanced international crushing technology as well as the world-class skills in making.

jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher application:

jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher---

Jaw crusher is suitable for crushing materials including granite,basalt,limestone,river stone,sandstone,shale,iron ore,copper ore,etc.And It is widely used in mining,metallurgy,building materials,road,railway,water conservancy,chemical industries,etc.

jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher working principle:

The motor will drive V-belts and transfer power to the pulley. The pulley will drive the eccentric shaft to make the upper jaw around eccentric shaft movement caused the whole mobile jaw plate movement up and down. When the moving jaw plate rises, the angle between bracket and the moving jaw will become large, which will promote the dynamic jaw plate to the fixed jaw close. At the same time, the materials will be crushed. When the moving jaw plate moves to the downward, the angle will become smaller and the moving jaw plate will leave the fixed jaw plate. At this time, the crushed materials will be discharged from the crushing cavity.

jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher spare parts:

1. Frame .

2. Stationary jaw plate .

3. Movable jaw plate .

4. Movable jaw .

5. Eccentric shaft .

6. Toggle plate .

7. Adjusting tuggle seat.

jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher characteristics:

1.World-class skills in making are adopted and the use of high-tech materials.

2. More advanced movable jaw assembly makes it more long-lasting.

Movable jaw assembly adopts a high-quality steel casting, and moves through two large cast steel flywheel drive. In addition, heavy eccentric shaft has also adopted forging billet for processing. All those make the rock crusher with exceptional reliability.

3. Integrated Cast Steel Structure Adopted in Axle Bearing housing.

Integrated cast steel structured axle bearing housing can guarantee to be perfectly cooperating with the crushing frame. Meanwhile, it greatly enhances the intensity of the axle bearing, which could not be performed in the separated styled axle bearing.

4. Use of finite element analysis technology makes the rock crusher with high intensity.

5. Summarized structure "V"adopted in the crushing cavity makes the actual feed mouth width equal to the set width of the feeding opening.

6. More quickly and convenient adjustment at the discharging opening.

European styled rock crushers are equipped with wedge adjustment devices, which is simpler, safer and faster than former gasket devices.

jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher engine parameters:

| Jaw crusher Model | Feed Opening (mm) | Max Feeding (mm) | Discharge Opening (mm) | Capacity (t/h) | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

| PEW250×1000 | 250×1000 | 220 | 20-40 | 15-50 | 330 | 6-37 | Y250M-6/37 | 1400×1850×1310 |

| PEW250×1200 | 250×1200 | 220 | 20-40 | 20-50 | 330 | 6-37 | Y250M-6/37 | 1400×2050×1310 |

| PEW400×600 | 400×600 | 350 | 35-85 | 15-70 | 250 | 6-37 | Y250M-6/37 | 1920×1460×1840 |

| PEW760 | 760×1100 | 620 | 75-200 | 150-350 | 270 | 6-110 | Y315L1-6/110 | 2600×2500×2200 |

| PEW860 | 860×1100 | 720 | 100-225 | 200-500 | 240 | 6-132 | Y315L2-6/132 | 3300×2320×3120 |

| PEW1100 | 1100×1200 | 930 | 150-275 | 300-650 | 210 | 8-185 | Y355L1-8/185 | 4140×2660×3560 |

PRODUCTION LINE

Customer profile

One if the locally biggest factories with the best field planning visited by local government delegation many times, setting foot in sandstone industry for the first time.

It purchase ZSW600*130 feeder machine. GZD200*120 feeder machine, PE1000*1200 jaw crusher, 2 sets of PFW1315 impact crushers, 2 sets of 3YA2160 oscillating screens, VSI1140 centrifugal impact crusher, 2YA2460 oscillating screen, XSD3016 wheel type sand wash, etc

Production line condition

Daily running: 9-10 hours

Feedstock: granite, size 400-600mm

Finished product: 30mm, 21mm gravel, sand

Configuration: ZSW600*130 feeder machine. GZD200*120 feeder machine, PE1000*1200 jaw crusher, 2 sets of PFW1315 impact crushers, 2 sets of 3YA2160 oscillating screens, VSI1140 centrifugal impact crusher, 2YA2460 oscillating screen, XSD3016 wheel type sand wash.

Main Specifications

| Model | Max.feed size(mm) | Setting Adjustment Range(mm) | capacity(TPH) |

| PE1000*1200 | 850 | 195-265 | 315-550 |

| PFW1315 | 600 | 180-320 | 160-200 |

| Model | Max.feed size(mm) | capacity(TPH) | Power(kw) |

| 2YA2460 | 400 | 150-700 | 37 |

| 3YA2160 | 400 | 100-500 | 30 |

| GZD200*120 | 300 | 80-500 | 2*2.2 |

Customer’s comment

Because I set foot in sandstone industry for the first time, I consult many fellow experts for configuration. Old experts very affirm the production line matched by Shibang Company for us. It is customized according to our stone and yield. We feel quite relieved. It is just suitable for use. Our local machine sand market is not only very good in this year, but also supported by policy. Therefore we also order sand-making machine, which is also because we trust in Shibang’s quality and service.

---Mr. Song, the Board Chairman and General Manager of this company

Click Here To Sent A Message Quickly

More successful case1.Andesite Crushing Plant In Indonesia

Configuration: PE Jaw Crusher, CS Cone Crusher, Vibrating Feeder, Vibrating Screen

Indonesia is one important market of SBM, every year, a number of SBM crushing machines, grinding mills and accessory equipments are transported to Indonesia. Our workers in oversea office workers of Indonesia has helped great many customers solve their problems and build the perfect processing line.

Customer's Background:

The year before last year, One customer from Bandung, Indonesia got in touch with our head office in China. He planned to build one andesite stone crushing plant and the requirements are generally as follows: The max feeding size should be about 400mm

The output size were three kinds: 0-10,10-20,20-30mm

The capacity of the plant should reach 50-70TPH (tons per hour)

2.Limestone and Granite Crush Plant in Iran

Configuration: PE Jaw Crusher, PFW Impact Crusher, VSI5X Crusher, Vibrating Feeder

Iran is a very important market of the Middle East. Every year, there are a lot of customers from Iran purchase crushers and grinding mills from SBM. We have widely winned the trust of customers and good reputation by providing high-quality equipments and technical services.

Customer's Background:

The customers contacted the professional sales man at SBM headquarter in Shanghai through on-line service of our website. He is planning to start a limestone crushing plant, and the requirements are as follows:

Raw material: limestone, granite

Max. feeding size: 250mm

Output size: 0-10mm

Capacity: 40-50 TPH

3. Laos iron ore processing plant

Configuration: PE Jaw Crusher, PY Cone Crusher, VSI Crusher

Laos became one important Southeast Asian market of SBM since 2005, two years later after the Austria SEPON gold ore processing plant started to work. Owe to our good public-praise, more and more Laos customers prefer to cooperate with SBM, and one SBM demo project—one 300TPH iron ore processing plant—begin to work at the beginning of 2014.

Customer's Background:

Time starting production: March, 2014

Material sourcing: Iron mine

Material type: Iron ore 75% 225tph; Clay 25% 75tph

Max. Feed size: 700mm

Moh’s hardness: 7-8

Designing processing production: 300TPH

Product size: 0-2mm 0.3%; 2-10mm 8.6%; 0-10mm 11.3%;10-40mm 81.5%.

4.Vietnam 300TPH Granite Crushing Plant

Configuration: PE Jaw Crusher, PY Cone Crusher, VSI Crusher

Vietnam is an important mining export country in Asia, especially the exportation of Limestone, iron ore, coal, granite and bluestone products. With many years’ effort, SBM successfully developed Vietnam market, SBM crushing machineries and milling equipments are very popular in many provinces, like Yen Bai province, Ho Chi Minh City, Nghe An, and Hanoi. These mining equipments make up various mining crushing lines, sand making plants and mineral powder production bases.

Customer's Background:

At the beginning of 2012, SBM salesman got one phone call inquiry from Vietnam Yen Bai, expressing that he visited one superfine limestone powder production line designed by SBM and he would like to know more about SBM. The Salesman Anne warmly welcome him visit SBM head-office and carefully help him analysis his requirements. After many negotiations, SBM design, 300TPH granite crushing plant, is highly-prized by the customer.

Packaging & ShippingWays of Packing:

1.Sand blasting, coat with high quality paint;

2.Product wrap by PP-Bubble

3.Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

Click Here To Sent A Message Quickly

Company Information

About SBM

SHANGHAI SHIBANG MACHINERY CO., LTD is one high-tech enterprise, which involves R&D, production, sales and service as well. In the past 20 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making high grade sand and matched equipments.Till now, our products are sold to 130 countries, being the popular equipments in global crushing and grinding industry.

The head office of SBM is in Shanghai- the international financial centre. Here we have professional R&D institution and technology team, which make us world-class company. Here all SBM machines are designed produced, assembled and texted according to the ISO9001:2008.

About SBM Factory

SBM (Shanghai shibang machinery Co.,Ltd) has three factories, the gross area is about 2.3 million square meters. Various world-class CNC are in these factories, such as CNC VTL OPERATOR, Planing Machine, CNC heavy-duty horizontal lathe. These advanced equipments ensure that our products are of precise specification. Also, we have professional Quality inspection division, every machines produced must be examined strictly, the quality is guaranteed.

The advantages of SBM company:

Minimum Order Quantity

A: The minimum order quantity is 1 Set

Delivery time

A: The lead time is 10-30 days, Delivery time will vary depending on the type of the machine, shipping method selected and part availability.

FOB Prices

A: Different machine has different FOB price, please send your interest type, raw material, capacity, Your contact information, we will give you a reasonable FOB price as soon as possible

Payment terms

A: Accepted Payment Type: T/T, L/C, Western Union, Cash

After sign the contract, pay the 10%-30% deposit of total purchase price and pay the full payment before delivery.

Products warranty

A: The Products warranty is one year.

Our ServicesAfter we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the product you purchased properly to your hands.

We will send a professional and high levels installation engineer team at the same time the product properly to the destination, in order to supply you a full range of products installation services. For some typical problems, our rigorous installed engineers also will do some certain installation debugging training, etc. Technological support SBM has been largely adopting new technologies, new techniques and high-tech equipments. And SBM also has strict and effective quality control system.

How to contact us?

Send your inquiry Details in the Below for Free detailed quotation, Click “send” Now!

please tell me your Material and Capacity

↓↓↓

Fine Crusher, gold hammer mill price is applicable for both dry and wet crushing.jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher grinder hammer mill crusher machine is widely used for medium or fine crushing Fine Crusher for medium hard and brittle materials by departments of mine, cement,jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher coal,building material, metallurgy, Fine Crusher chemical industry, road construction,gas chemical industry and jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher thermal power generation, etc. Coal gangue,coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains,alum, brick and tile, etc.

HSFGYGDJ

When the Fine Crusher is working, materials are crushed primarily in the first crushing chamber by the high speed moving rotor against the hammer, and then enter the secondary chamber for fine crushing, at last, the final materials are discharged.jaw crusher crushing stone rock crusher, jaw crusher fine, toothed roller crusher adopts "stone-stone" principle with a huge arc-shaped crushing cavity, which is a screen cavity with grate seam

JHBJHVJK