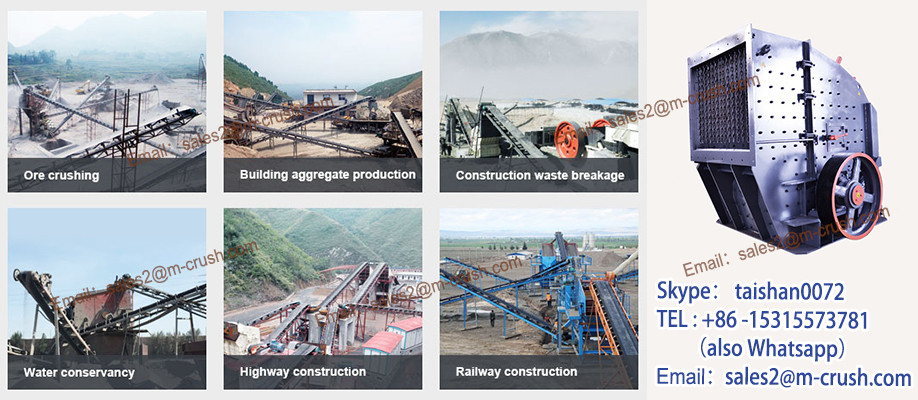

Application of PF series Impact Crusher machine :

Impact Crusher can crush many kinds of large, medium, small materials such as rock or stone whose

side length is less than 500mm, and compression resistance should not be more than 350Mpa. And The

impact crusher (impactor) is widely used in hydroelectricity, highway, artificial rock, stone and sand,

building material, etc.

Working Principle of the PF series impact crusher machine :

When the impact crusher works, the motor drives the rotor rotate with high speed, on the rotor where

installed the hammers. When the materials get into the area which the hammers effect, under the impact

function of the hammer at a high speed, the materials are thrown to the impact device above the rotor

continuously. And then the materials are rebounded from the impact liner to the area where the hammers

effects for being re-crushed. The materials from large to small all to be crushed at the impact chamber

repeatedly.The process won’t stop till the material are crushed to the required size and then discharged

from outlet.

Our PF series Impact crusher machine has:

1. Largecapacity: big feed opening, high crushing cavity, suitable for materials with high hardness, large

block, and few stone powers.

2.High ratio of reduction: impact crusher has larger crushing ratio than hammer crusher. It can make full

use of the high-speed impacting energy of the whole rotor.

3. Perfect structure: compact structure, strong rigidity of machine, the rotor has a large rotational inertia

4. Large adjustable range: the gap between impact plate and board hammer can be adjusted, effectively

controlling the discharged material size, with good particle shape.

5.Good wear-resistance:high -chromium board hammer is wear resisting enough to bear strong impact

force.

6.Easy maintenance: keyless connection, easy to maintain, reliable and economical

7. Wide range of choices:we provide different dimensions of product which can meet various needs

Technical parameter:

| Model | specifications (mm) | Feeding size(mm) | Biggest size of material(mm) | Capacity (t/h) | Motor power(kw) |

| PF-0607 | ø-644*740 | 320*770 | 100 | 10-20 | 30 |

| PF-0807 | ø-850*700 | 400*730 | 300 | 15-30 | 30-45 |

| PF-1008 | ø-1000*800 | 400*830 | 300 | 30-50 | 37-55 |

| PF-1010 | ø-1000*1050 | 400*1080 | 350 | 50-80 | 55-75 |

| PF-1210 | ø-1250*1050 | 400*1080 | 350 | 70-120 | 110-132 |

| PF-1212 | ø-1250*1250 | 400*1300 | 350 | 100-150 | 132-160 |

| PF-1214 | ø-1250*1400 | 400*1430 | 400 | 130-180 | 160-200 |

| PF-1315 | ø-1320*1500 | 860*1520 | 500 | 160-250 | 180-260 |

| PF-1320 | ø-1320*2000 | 860*2030 | 500 | 300-350 | 300-375 |

WELCOME TO VISIT OUR COMPANY!

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.rock cutting equipment impact crusher is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the rock cutting equipment impact crusher works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. rock cutting equipment impact crusher The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK