reversible impact hammer crusher

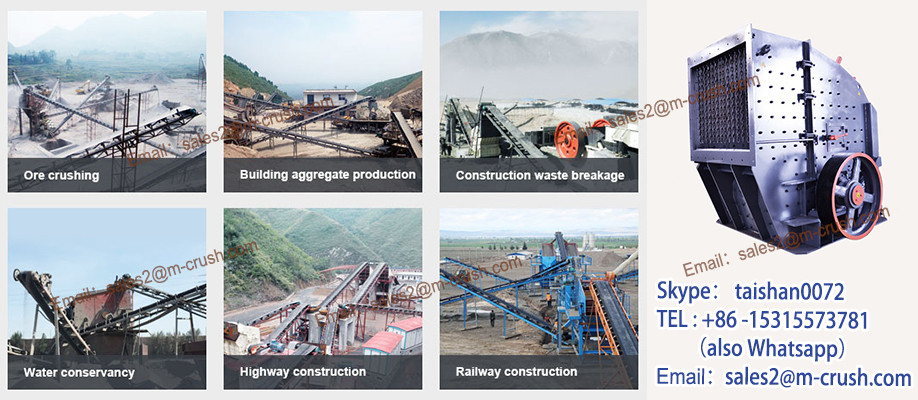

The impact crushers are ideal for secondary crushing. impact crusher is a new stone crusher machine that absorbs advanced technologies at home and abroad. Dealing with the material with the side length 500mm, not more than 350Mpa anti-pressure strength, impact crusher can be widely used in the first and secondary crushing process. The impact crusher designed by us is characterized by great reduction ratio, high reduction efficiency, convenient maintenance, etc, impact crusher is widely used in crushing plant for highway construction, hydraulic engineering and architecture, mining industry etc for crushing quartz, basalt, shaly, kaolin, limestone, marble etc

1.Even crushing function of multi-cavities which is suitable to crush Hard material.

2.Reasonable design of leveling plate making the finished material finer and cubic- shaped without internal cracks.

3.Hydraulic start-up which is convenient for maintenance and replacement of wearing parts.

4.New anti-abrasive material which prolong service life of impact hammer, impact plate and liner.

When impact crusher works, the motor drives the rotor rotate with high speed, on the rotor where installed the hammers with high-tech raw material. When the crushed materials get into the impact crusher inner space where the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. The materials from large to small all to be crushed at the impact crusher chamber repeatedly. The process won't stop till the materials in the impact crusher are crushed to the required size and then discharged from outlet.

More Pictures of Impact Crusher:

impact crusher installation

Type |

Specification(mm) |

Max feed size (mm) |

Capacity (t/h) |

Motor Power (KW) |

Weight (t) |

PF-0504 |

Φ500×400 |

100 |

4-8 |

7.5 |

1.6 |

PF-0807 |

Φ800×700 |

100 |

15-30 |

22 |

3.5 |

PF-1007 |

Φ1000×700 |

200 |

30-50 |

37 |

8.5 |

PF-1010 |

Φ1000×1050 |

250 |

50-80 |

55 |

12.1 |

PF-1108 |

Φ1100×850 |

300 |

60-100 |

110 |

13.5 |

PF-1210 |

Φ1250×1000 |

350 |

80-135 |

110 |

14 |

PF-1214 |

Φ1250×1400 |

450 |

130-180 |

132 |

18.6 |

PF-1315 |

Φ1320×1500 |

600 |

160-250 |

160 |

19 |

MFD-20 |

Φ750×500 |

200 |

8-20 |

30 |

1.9 |

MFD-50 |

Φ750×700 |

200 |

10-20 |

75 |

2.6 |

MFD-100 |

Φ1000×700 |

200 |

15-30 |

130 |

5.4 |

MFD-120 |

Φ1250×1000 |

200 |

80-110 |

240 |

7.2 |

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.reversible impact hammer crusher is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the reversible impact hammer crusher works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. reversible impact hammer crusher The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK