Related Products

Construction Portable Mobile PE Crushing Machine Gold Mining Stone And Rock Jaw Crusher

Min. Order: 1 Set , Jaw crusher can be OEM

FOB Price: US $ 4705 - 82352 / Set

Industry Mobile High Temperature Material Use After Sintering Single Tooth Roll Crusher

Min. Order: 1 Set , Single tooth-roller crusher can be OEM

FOB Price: US $ 57647 - 176470 / Set

Hard Material Large Crushing Ratio Ore Mining Machine Four Teeth Roller Crusher

Min. Order: 1 Set , Four Teeth Roller Crusher can be OEM

FOB Price: US $ 30290 - 138970 / Set

High Efficiency Mobile Industrial Stone Mining Use First Step Crushing Equipment Hammer Crusher

Min. Order: 1 Set , Hammer crusher can OEM

FOB Price: US $ 3088 - 78676 / Set

Mobile Fine Quarry Primary And Secondary Crushing Ore Stone Hydraulic Cone Crusher

Min. Order: 1 Set , Cone crusher can be OEM

FOB Price: US $ 17647 - 147058 / Set

Mobile Mining Equipment Stone Rock Coal Sand Making Vertical Shaft Crusher

Min. Order: 1 Set , Vertical shaft crusher can be OEM

FOB Price: US $ 4588 - 15440 / Set

Hot Sale High Efficiency Concrete Rock Crushing Machine Price Limestone Crusher

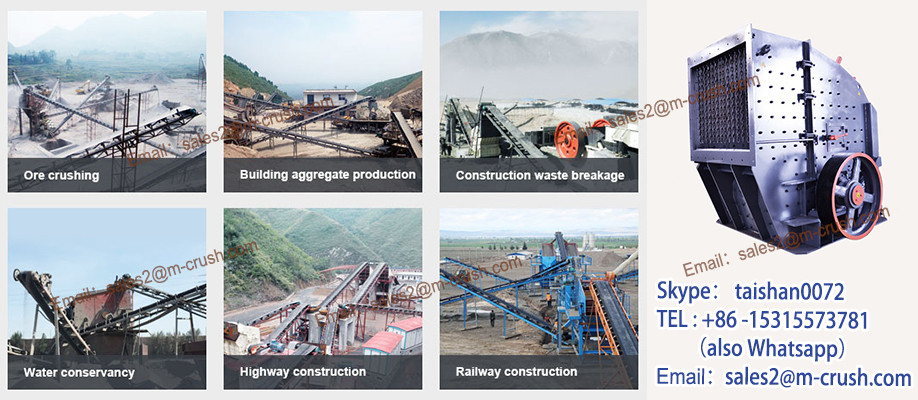

Limestone crusher widely used for crushing materials in building materials, ore crushing, railway, highway, energy, transportation, energy, cement, mining, chemical and other industries.

Rock crusher machine price is a new type of high efficiency crushing equipment. applicable for the materials’ size between 100 mm and 500 mm, the strongest anti-crush pressure is less than 350 Mpa.

| Type | Spc. (mm) | Weight (t) | Designed capacity (t/h) | Size(mm) | Motor power(KW) | Feeding size | Discharge size | Roller speed |

| PF-54 | Φ500×400 | 1.4 | 4-8 | 1495×1152×1010 | 7.5 | 970r/min | ||

| PF-107 | Φ1000×700 | 6.2 | 30-50 | 2170×2650×1850 | 45 | ≤250mm | ≤30mm | |

| PF-1210 | Φ1250×1000 | 14.8 | 45-80 | 4025×3967×2850 | 115 | ≤20mm | 680r/min | |

| PF-1315 | Φ1320×1500 | 21 | 100-180 | 3329×2613×2705 | 220 | ≤300mm | ≤10mm | |

| 2PF-1010 | Φ1000×1000 | 24 | 57-70 | 4360×3380×3200 | 75 75 2.2 |

Frist: 640r/min Second : 860r/min | ||

| 2PF-1212 | Φ1250×1250 | 53 | 100-140 | 5025×5614×4053 | 130 155 2.2 |

Frist: 530r/min Second: 680r/min |

Principle

Principle

| The size and shape of discharged materials can be changed by adjusting the distance between counter-attack plates and rotor. Concrete crusher mainly used in metallurgy, mining, cement, chemical, refractory materials and ceramics and other industrial sectors, as well as highway construction, water conservancy projects, construction, gravel, machine-made sand processing and other fields. | |

| Impact stone crusher uses impacting force to crush material. During working, the rotor is driven by the motor to keep high rolling speed. Material is hit by the hammer of the rotor and threw to the counter-attack plate to be hit again | |

Advantage

AdvantageⅠ. Smaller size, larger capacity. bigger feeding mouth, harder materials to process.

Ⅱ. Low power consumption and high efficiency.

Ⅲ. High crushing ratio which is up to 40%. Save the cost.

Ⅳ. The gap between counter-attack and the hammer can be adjusted conveniently,

Ⅴ. Chrome hammer, high impact force and wear resistance.

Ⅵ. Non-key connection to examine and repair, economical and reliable.

Ⅶ. More kinds of materials for crushing, high capacity, Low parts abrasion. High efficiency.

Ⅷ. Selective crushing, mostly, uniform sizes and cube shape of discharge material,

FAQQ1. How to install the equipment?

FAQQ1. How to install the equipment?A1. We have the installation instruction book for customer reference first. if any problem we can contact our engineer guide the installation by video call.

Q2. What kind of material can the Impact Crusher crush?

A2. Stones, feldspar, calcite, talc, barite, rare earth, clay, dolomite, kaolin, gypsum, graphite ect.

Q3. What is the compression strength of the Impact Crusher?

A3. Impact Crusher can crush the materials under 350Mpa.

Q4. What is the feeding size of the Impact Crusher?

A4. Impact Crusher can crush the material from 100 - 500 MM.

Q5. What is the wearing parts for the impact crusher?

A5. Liner; Counter Strike Board (1); Counterattack board (2); Plate; Door lining; Plate hammer; Insurance pin sets; Bushings; Insurance sales; Spherical roller bearings AK / W33

About Us

About Us

Chaoyang Heavy Machinery Manufacturing Co., Ltd 's main business is the EPC turnkey engineering and professional equipment for the following industries: chemical, metallurgical industries of all sizes of active lime production line; cement industry Nissan 2500 tons of cement production line; power industry coal grinding machine, flue gas desulphurization facilities of limestone powder of preparing students production line; in non-ferrous metal metallurgy, metal magnesium calcined dolomite and zinc oxide production line; beneficiation process crushing, grinding ore, classification, magnetic separation, flotation, filtration, concentration, mixer and other complete sets of equipment.

Provide a variety of complete sets of equipment for the annual production capacity of 10 million tons and above large mines; petroleum industry of new energy-saving type gravity balance oil pumping machine with special equipment.

Contact Us

Contact Us

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.Hot Sale High Efficiency Concrete Rock Crushing Machine Price Limestone Crusher is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the Hot Sale High Efficiency Concrete Rock Crushing Machine Price Limestone Crusher works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. Hot Sale High Efficiency Concrete Rock Crushing Machine Price Limestone Crusher The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK