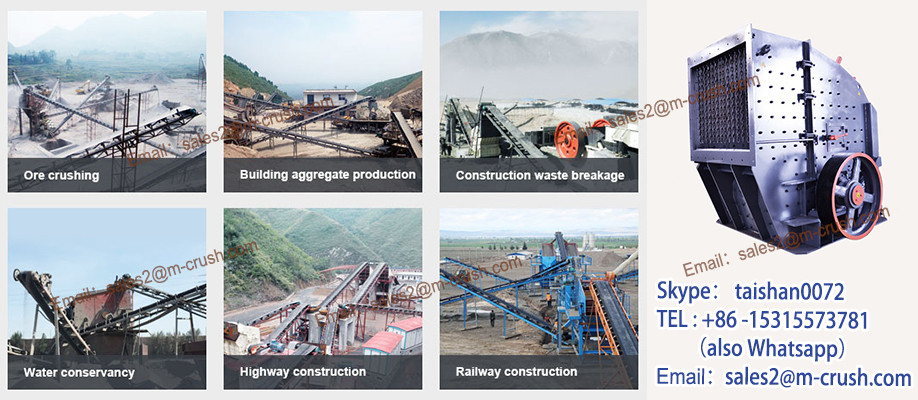

1.Impact Crusher picture  2. 2.impact crusher mpact Crusher Specifications:

2. 2.impact crusher mpact Crusher Specifications:

| Model | Rotor Spec(mm) | Feed Opening Size(mm) | Max Feed Edge(mm) | Capacity (t/h) | Motor Power(kw) | Weight (t) | Dimensions (L×W×H) (mm |

| PF- 1007 | 1000×700 | 400×730 | 300 | 30-70 | 45 | 12 | 2330×1660×2300 |

| PF- 1010 | 1000×1050 | 400×1080 | 350 | 50-90 | 55 | 15 | 2370×1700×2390 |

| PF- 1210 | 1250×1050 | 400×1080 | 350 | 70- 130 | 110 | 17.7 | 2680×2160×2800 |

| PF- 1214 | 1250×1400 | 400×1430 | 350 | 100- 180 | 132 | 22.4 | 2650×2460×2800 |

| PF- 1315 | 1320×1500 | 860×1520 | 500 | 130- 250 | 220 | 27 | 3180×2720×2620 |

3. Stone Impact Crusher Description:

The Impact Crusher manufactured by Shanghai Yike Road & Bridge Machinery Co.,Ltd has widely exported to Middle East(Saudi Arabia, Oman), America(Canada), Africa(Algeria, Rwholesale sand/rock/stone/jaw/cone/impact crusher for crushing machine wholesale online, Cameroon etc.), Southeast Asia(Vietnam, Philippine, Indonesia, India etc.), and our brand "YK" has won a good reputation from our clients all over the world by good quality, satisfied service and continuous and timely supply at competitive prices for wearing parts. Because of Impact Crusher simple structure and reliable operation, easy maintenance and low operating cost, they have been widely applied to Mining, Metallurgy, Building Materials, Road, Railway, Water Conservancy, Chemical Industry field etc. to process Granite, Basalt, Bank/River Gravel, Limestone, Marble, Bauxite, Silicon Carbide, Iron Ore, Concrete Aggregate, Cement Clinker, Quartz, Slag etc.

4.stone Impact Crusher Working Principle:

This PF Series Impact Crusher is used in Secondary Crushing. The Impact Crusher can crush material whose compression strength is not more than 350Mpa. The detailed specification is like below for your selection.

5.stone Impact Crusher Features and Benefits:

1.Even crushing function of multi-cavities which is suitable to crush Hard material.

2.Reasonable design of leveling plate making the finished material finer and cubic-shaped without internal cracks.

3.Hydraulic start-up which is convenient for maintenance and replacement of wearing parts.

4.New anti-abrasive material which prolong service life of impact hammer, impact plate and liner. 6.The Photos of stone Impact Crusher in Use recently;

7. We also supply impact crusher wear parts and fastener parts with good quality and good price in China and overseas.

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.wholesale sand/rock/stone/jaw/cone/impact crusher for crushing machine wholesale online is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the wholesale sand/rock/stone/jaw/cone/impact crusher for crushing machine wholesale online works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. wholesale sand/rock/stone/jaw/cone/impact crusher for crushing machine wholesale online The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK