Introduction of VSI Vertical Shaft Impact Crusher:

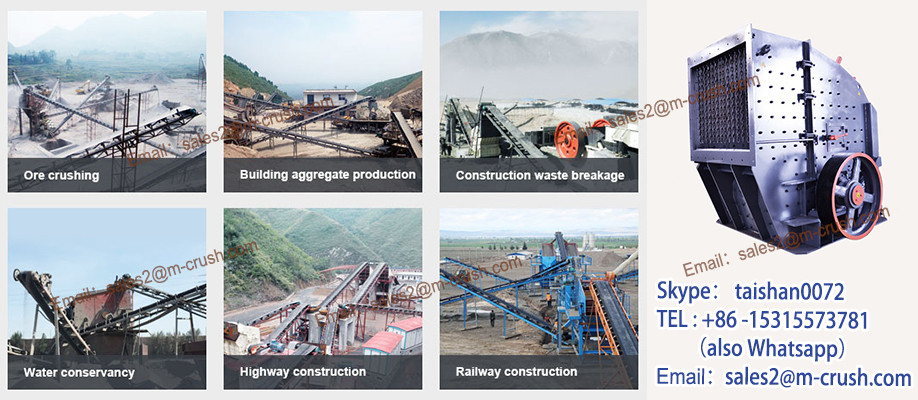

VSI Vertical Shaft Impact Crusher is designed by German authoritative experts according to Chinese local working condition. It is a kind of sand making machine of world high-level performance produced exclusively in China. The machine provides high-quality materials especially for motorway,high-speed railway,tall building,city project,hydroelectric damconstruction and concrete mixing station. VSI is the first and the best choice for the field of man-made sand and stone shape.

Simply put, the inverter is a equipment turn low voltage (12 or 24 volts or 48 volts) direct current into 220 volts AC electronic . Because we are usually transfer 220 volts AC rectifier into DC, but the role of the inverter is on the contrary, hence the name. We are in the era of a "mobile" century, mobile communications, mobile recreation and entertainment. In the state of mobilement , not only by battery or battery low-voltage DC are supplied , but also 220 volts AC inverter is indispensable in our daily environment , the inverter can meet this demand.

Advantages of VSI Vertical Shaft Impact Crusher:

- Large capacity and high yield, Compared with the same power equipment, its production increase 30 percent, and is relatively stable.

- Low consumption of vulnerable parts.

- Product grain shape excellent.

- Hydraulic device, easy to maintain.

- Automatic detection, safe and reliable.

- Thin oil for lubrication, automatic maintenance.

- Easy to install, easy to operate.

- Multi-usage, flexible application.

- International quality assurance.

- Pay attention to environmental protection.

Structure of VSI Vertical Shaft Impact Crusher:

Technical Parameters of VSI Vertical Shaft Impact Crusher:

| Model | VSI7611 | VSI8518 | VSI9526 | VSI1140 | |

| Capacity(t/m) | Feed both at center and at sides | 120-180 | 200-260 | 300-380 | 450-520 |

| Feed at center | 60-90 | 100-130 | 150-190 | 225-260 | |

| Best Feed Size(mm) | Sofe Material | 35 | 40 | 45 | 50 |

| Hard Material | 30 | 35 | 40 | 45 | |

| RotationSpeed(r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Double Motor Power(kw) | 110 | 180 | 264 | 400 | |

| Overall Dimension L*W*H(mm) | 3700*2150*2100 | 4140*2280*2425 | 4560*2447*2778 | 5000*2700*3300 | |

| Weight(t) | 11.8 | 14.5 | 17.8 | 25.6 | |

| Power Supply | 380v 50Hz | ||||

| Vibrating Sensor | Detect Range:0.1-20mm/s continuous and adjustable | ||||

| Lubrication and hydraulic station | Double Motor Power | 2*0.31kw | |||

| Safety assuance | Double oil pumps assure enough oilsupply:automaticswitvh off with no oil stream or hydraulic strength:lower the temperature with cool water in summer;raise the temperature with motor in winter. | ||||

| Overall DimensionL*W*H(mm) | 820*520*1270 | ||||

| Power of oil tank heater | 2kw | ||||

Certification:

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.Hot!!! VSI Vertical Shaft Impact Crusher For Sale is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the Hot!!! VSI Vertical Shaft Impact Crusher For Sale works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. Hot!!! VSI Vertical Shaft Impact Crusher For Sale The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK