Product Description

Some equipment such as hammer crusher, impact crusher, big wet ore grinding machine, they bear biggish impulsive force during the process of actual operation. The wet ore grinding machine has the abrasion feature. Thus need the liner material with higher abrasion performance and higher impact toughness also would be safety and reliability during the operation period. The only choose of this working condition is high Mn series material.

The high Mn liner make by our company use the advanced production technology, strictly control the dosage of recycled scrap in order to make the chemical component meet the requirements of the using performance. We making feasible heat treatment process scheme according to the liner’s complexity, thickness, and the requirement of using. Make sure all the section of the liner is austenite structure. We use the grinding wheel polish all the assembly hole, Grinding flat all the assembly surface, make sure the precision of assembly size. Our purpose is provide satisfactory service to our customers.

Our products

Luoyang Zhili New Materials CO., Ltd was founded in 1992, Which specialized in producing wear- resistant steel company, professional of the crusher hammer. We passed the ISO9001:2000.

During 25 years we establish cooperation with many respected customer such as CRH(Ireland),POSCO(Korea),Holcim(Swden),CEMEX (Mexico, Egypt),ARCELORMITTAL (Algeria),Magaldi Power S.p.A.(Italy),IMCO Alloys Pvt. Ltd(India),CA POLYTECH PVT.LTD(India),LAFARGE(Morocco, Romania, China).

Related Products

Related Products

FAQ

FAQ1.Q: What's your company's casting methods?

A:We support sand casting and lost foam casting.

2.Q: Can you make products without drawing?

A: No, we can only make products strictly follow customers' technical drawing.Because every spare parts must be install to the equipment.even little error can make big problem without technical drawing.

3.Q:What's brand do you manufacture?

A:We supply casting spare parts for many customers all over the world, OEM is accept.

4.Q:How long is your products' lifetime?

A: Even the same products,different working condition has different lifetime.So please let us know your working condition we can give you some technical suggestion.

5.Q:What's the delivery time?

A: Usually we the delivery time is 35 days. But we will arrange the Production Scheduling as customers' requirement.

6.Q:What's the payment term does your company accept?

A: 30%T/T in advance, the balance pay off before delivery.

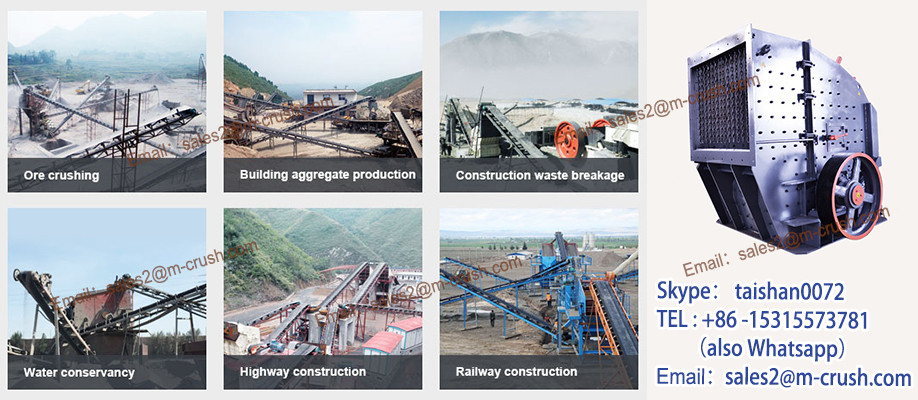

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.SGS Certificate Mn18Cr2 rock crusher spares part is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the SGS Certificate Mn18Cr2 rock crusher spares part works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. SGS Certificate Mn18Cr2 rock crusher spares part The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK