Construction Portable Mobile PE Crushing Machine Gold Mining Rock And Stone Jaw Crusher

Product DescriptionBrief Introduction of Jaw Crusher

Jaw crusher is the main stone crusher.One of the most popular stone-crushing equipments in the world, Jaw Crusher is ideally suitable for primary and secondary crushing. The highest anti-pressure strength of crushed material is 320Mpa. Our design and production are of high position both at home and abroad.

Jaw crusher can be used as the primary crusher to the medium size crushing of various ores and large-size materials , with the anti-crushing pressure of less than 320Mpa.And the jaw crusher can be divided into two kinds such as coarse and fine crushing .And this series of jaw crusher have complete specifications with the feeding particle size of 125mm~750mm.

Various types of Jaw Crusher

Various types of Jaw Crusher

Part of Jaw Crusher

Working principle of jaw crusher

This jaw crusher uses motor as its power, through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track.

Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can be crushed and discharged through the discharging opening.

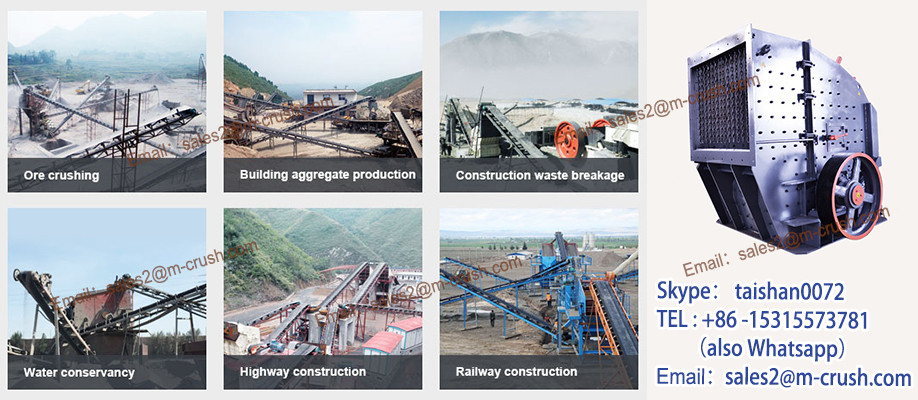

Working environment of the jaw crusher

The crushing process that the large stone become small stone is called the primary crusher .And the most common and solid crusher is the jaw crusher. During the feeding process of the jaw crusher ,the materials can enter the crushing cavity with the jaw gear from the top entrance .And the jaw gear will push forward the materials to the cavity with the strong force to crush them to some more small stones .And it is a eccentric shaft to support the movement of the jaw gear ,and this shaft have supported the whole machine frame .And the eccentric movement is caused by the flywheel fixed on the both end of the shaft .The flywheel and eccentric supporting bear often adopt the spherical roller bearing so that the working environment of the bearing is more hard .And the bearing must bear the huge impact overload ,erosion water pollution and the high temperature .However ,the Jaw crusher can also ensure the reliable work ,which have also become the key link of the production effect. Though the hard working environment, the jaw crusher can still proceed the very reliable function, which is the key link of the production efficiency.

On-Site of use Jaw Crusher

Product Date

| Model | Max feeding size(mm) |

Asjustable range of discharging (mm) |

Capacity(t/h) | Power(Kw) | Main shaft RPM(r/m) | Dimension (LxWxH) (mm) |

Weight (t) |

| PEF100x150 | 90 | 5-20 | 0.4-1.8 | 2.2 | 380 | 615x449x520 | 0.6 |

| PEF150x250 | 125 | 10-40 | 1-4 | 5.5 | 300 | 875x750x950 | 1.3 |

| PEF250x400 | 210 | 20-80 | 4-14 | 15 | 280 | 1108x1090x1392 | 2.8 |

| PEF400x600 | 350 | 40-110 | 10-40 | 30 | 275 | 1663x1732x1586 | 6.7 |

| PEF500x750 | 425 | 50-120 | 30-90 | 55 | 250 | 1930x2062x2246 | 11.5 |

| PEF600x900 | 480 | 75-200 | 56-192 | 75 | 250 | 2600x3700x2400 | 17.6 |

| PEF750x1060 | 630 | 80-210 | 72-300 | 110 | 225 | 2531x2370x2783 | 26.8 |

| PEF900x1200 | 750 | 100-220 | 150-330 | 132 | 218 | 3135x2966x3220 | 49.8 |

| PEF1000x1200 | 780 | 195-270 | 190-280 | 160 | 200 | 3480x2876x3330 | 54.7 |

| PEF1200x1500 | 1020 | 150-300 | 270-500 | 200 | 180 | 4300x3780x4043 | 96.8 |

| PEF1500x1800 | 1200 | 220-350 | 400-800 | 280 | 180 | 5160x3660x4248 | 120.8 |

| PEX100x500 | 80 | 7-20 | 3-15 | 7.5 | 320 | 940x1120x870 | 1.5 |

| PEX150x750 | 120 | 10-40 | 8-35 | 15 | 310 | 1215x1520x1030 | 2.9 |

| PEX250x750 | 210 | 12-45 | 13-45 | 22 | 300 | 1400x1697x1412 | 4.8 |

| PEX200x1000 | 210 | 13-50 | 15-50 | 30 | 300 | 1465x1800x1030 | 5.4 |

| PEX250x1000 | 210 | 15-50 | 20-60 | 37 | 330 | 1530x1992x1380 | 6.8 |

| PEX250x1200 | 210 | 15-60 | 25-70 | 45 | 330 | 1840x2192x1580 | 7.9 |

| PEX300x1300 | 250 | 20-90 | 20-130 | 55 | 280 | 1850x2320x1724 | 12.6 |

| PEX400x1200 | 340 | 20-80 | 30-150 | 55 | 275 | 1900x2500x1800 | 13.3 |

Henan Xingyang Mining Machinery Manufactory is a mining machinery manufacturer .The Construction Portable Mobile PE Crushing Machine Gold Mining Rock And Stone Jaw Crusher products include whole set mine-selecting equipment and sandstone equipment, such as ball mills, crushers, grinders, magnetic separators, flotation machines, classifiers, driers, sand-makers, vibrating screens, sand washers, conveyors and so on.

Service for clients

1. Work flow design

2. Machinery choose

3. Machinery planning

4. Machinery installation

5. Worker train

6. Supply wear parts and spear parts

7. Expanding design

FAQ1.How is the quality of your product?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2.Guaranteed:

If product quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about Price?

We are manufacturer of 20 years experiences, and be able to give you the lowest price than market one, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.Construction Portable Mobile PE Crushing Machine Gold Mining Rock And Stone Jaw Crusher is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the Construction Portable Mobile PE Crushing Machine Gold Mining Rock And Stone Jaw Crusher works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. Construction Portable Mobile PE Crushing Machine Gold Mining Rock And Stone Jaw Crusher The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK