Product Description

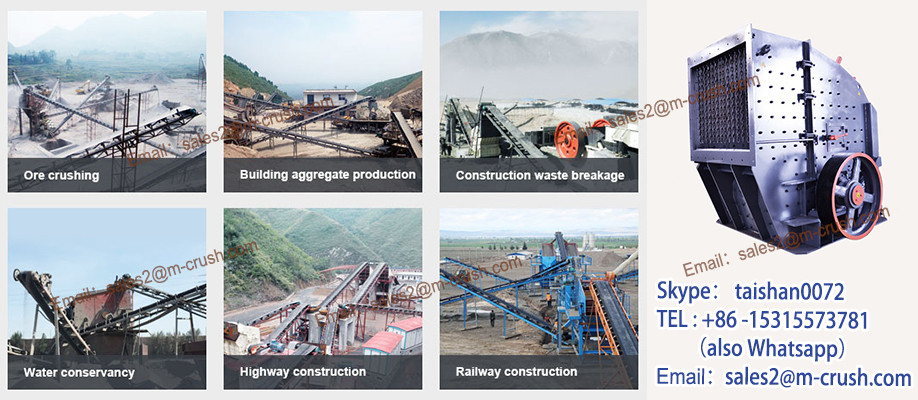

Application of Stone crushing plants-Jaw crusher pe 600 900 hammer breaker rock with screen for sale

Stone crushing plants are applied to cement mill, mining, building construction, road &bridge construction, railway construction and metallurgy and some other industries. Materials like iron ore, granite, limestone, quartzite, coal, gypsum,sandstone, gravel, river stone, marble, gold ore, cobblestone...

Process introduction:Big materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing. After first crush, the material will transferred to impact crusher by belt conveyor for secondary crush; the crushed materials will then transferred to vibrating screen for separating. This step is very important in crushing lines. After separating, the parts that can meet standard will be transferred away as final products, while the unqualified products will be returned to impact crusher, thus forming a closed circuit. Size of final products can be combined and graded according to customer’s specific requirement. We can also equip dust catcher system to protect environment if needed.

Main Features

The whole crushing line is fully automatic and sizes of the final products are even, good-shaped and can be adjustable, with high crushing ratio, low power consumption and high capacity, which is suitable for big, middle and small projects, such as road and bridge constructions.

Jaw Crusher

Impact Crusher

Cone Crusher

Mobile Crushing Station

Ball Mill

Single Cylinder Cone Crusher

Production Site

Project of 3000 ton per day gold benefication production line in Kenya and Zimbabwe - RIOZIM Company

| Equipment list of the crushing system | |||

| NO. | Equipment | Function | Model |

| 1 | Vibrating Feeder | The major feeding equipment to feed raw materials into primary crushing. | GZD1100X4200 |

| 2 | Jaw crusher | The heavy duty jaw crusher usually plays role as primary crushing machine. | PE-750X1060 |

| 3 | Hydraulic cone crusher | Cone crusher is widely used as secondary crushing machine, especially for hard stone, like gold ore, marble...and shape of the finished product is very good. | FXGYS-400-C |

| 4 | Hydraulic cone crusher | FXGYS-400-F | |

| 5 | Vibrating screen | The major sieving equipment to separate the raw crushed materials | 2YK2460 |

| 6 | Belt conveyor,silo and steel frame | ||

40 -60 TPH Stone Crushing Production Line

Hopper + vibrating feeder + jaw crusher(PE-400×600) + impact crusher (PF-1007) or cone crusher (φ 600&900) + vibrating screen

80 - 120 TPH Stone Crushing Production Line

Hopper + vibrating feeder + jaw crusher(PE-600×900) + impact crusher (PF-1214) or cone crusher (φ 900&φ1200) + vibrating screen

150 - 200 TPH Stone Crushing Production Line

Hopper + vibrating feeder + jaw crusher(PE-750×1060) + impact crusher (PF-1315) or cone crusher (HP300) + vibrating screen

250 - 300 TPH Stone Crushing Production Line

Hopper + vibrating feeder + jaw crusher(PE-500×750) + two impact crushers (PF-1315) or cone crusher (HP400) + vibrating screen

Our Service

Our Service

1. Pre-sale services:

1>. Select proper equipment model;

2>. Design and manufacture products according to clients' special requirement;

3>. Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

4>. Make sure goods prepared within delivery time;

5>. Pre-check and accept products ahead of delivery;

6>. Prepare documents required to help customer pass customs clearance.

2. After-sale services:

1>. Assist clients to prepare for the first construction scheme;

2>. Install, debug and examine the equipment;

3>. Train technical personnel the first-line operators;

4>. Provide technical exchanging

5>. Offer spare parts at a best price for long term.

Contact Us

Contact UsSend Message or Chat Now for Latest price!!!

Tips: please tell me your material and capacity to become our quality clients which will have 2%-10% discount

please tell me the following questions, so we can send you accurate quotation with additional discount:

♥ What's the raw materials you want to process(such as limestone)?

♥ What is capacity you want tons per hour? such as5TPH, 10TPH, 20TPH

♥ Your email address or phone number

♥ Other requirements. (We are the Jaw crusher pe 600 900 hammer breaker rock with screen for sale manufacturer of mining machinery: jaw crusher, impact crusher, cone crusher, sand making machine, mobile crushing plant, vibrating feeder, vibrating screen, belt conveyor, raymond mill, ball mill, rotary dryer, rotary kiln, sand washer...)

♥ Or you can contact me by Whatsapp: 0086 187 2124 3106

↓↓↓

| Contact person | Lola Chen |

| Phone number(office) | 0086 21 50808756 |

| Mobile(Whatsapp&viber) | 0086 187 2124 3106 |

| Skype | chen.aurora1 |

| c1217198127 | |

| Website | www.sinofxm.com |

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.Jaw crusher pe 600 900 hammer breaker rock with screen for sale is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the Jaw crusher pe 600 900 hammer breaker rock with screen for sale works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. Jaw crusher pe 600 900 hammer breaker rock with screen for sale The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK