Product Description

PF Series Impact Crusher,industrial aggregate crushers for sale

PF Series Impact Crusher can use impact energy to crush the materials. The rotor rotates at a high speed by the driving of motor, and the materials entering from the inlet impacts the plate hammer on the rotor and would be crushed under the high-speed impact of the plate hammer; the crushed materials would be thrown back to the liner plate for crushing again; finally, the materials are discharged from the outlet.

| Model | Rotor XL (mm) | Feed Opening (mm) | Max Feeding (mm) | Capacity (t/h) | Power (kw) | Motor Model | Machine Size (mm) |

| PF1010 | 1000X1050 | 400×1080 | 350 | 50-80 | 4-75 | Y280S-4/75 | 2455×2086×2800 |

| PF1210 | 1250×1050 | 400×1080 | 350 | 60-120 | 6-110 | Y315L1-6/110 | 2590×2050×2810 |

| PF1214 | 1250×1400 | 400×1430 | 350 | 80-160 | 6-132 | Y315L2-6/132 | 2590×2400×2810 |

| PF1315 | 1300×1500 | 860×1520 | 350 | 120-260 | 6-200 | Y355M3-6/200 | 2930×2760×3050 |

Adopt plate hammer made from highly wear-resistant material, Factory direct prices industrial aggregate crushers for sale service life

The plate hammer of PF impact crusher is cast from high chrome material and wear-resisting material through composite process, and undergoes strict heat treatment, so that it possesses good mechanical shock resistance and thermal shock resistance.

Semi-automatic safety design effectively reduces the overload risk and maintenance downtime

PF impact crusher is equipped with self-weight safety device on the rear upper rack. After the non-crushing material (e.g. iron block) entering into the crushing cavity, the front and rear impact racks will move back, and the non-crushing material will be discharged from the machine; when the crusher resumes working, the impact racks will return to their normal working positions with the help of self-weight safety device, thus avoiding the risks generated due to equipment overload and the losses caused by shutdown and maintenance.

Top mechanical adjustment device design easily realizes the adjustment of size of the discharged material

For different market requirements of the user at different stages, we set a mechanical adjustment device on the top of PF impact crusher, and the user can adjust the spacing between the impact rack and rotor through twisting the bolt of this device, so as to realize the adjustment of size of the discharged material.

Adopt ratchet wheel flapping device, replacing parts and other service operations become faster

PF impact crusher is installed with two identical sets of ratchet wheel flapping devices on both sides of the rack, which is composed of high-strength left and right spiral trapezoidal screw and ratchet wheel reversing mechanism. When the impact crusher needs be stopped for parts replacement and other maintenance and service operations, the user can easily and stably open and close the rear upper cover of the impact crusher through this device for service operations.

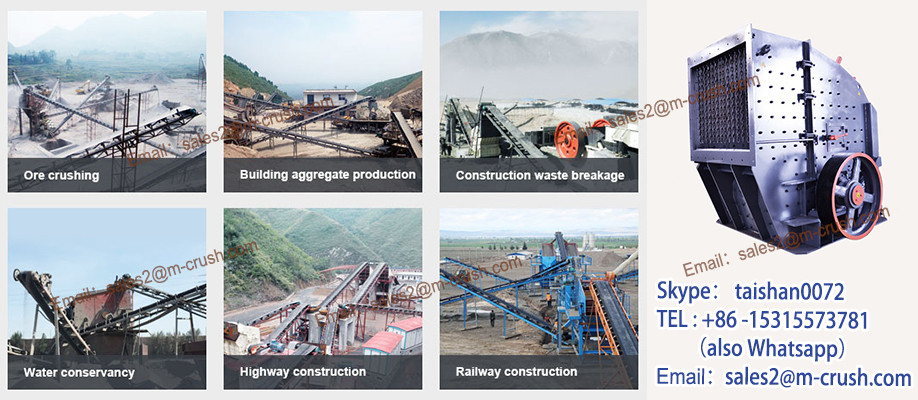

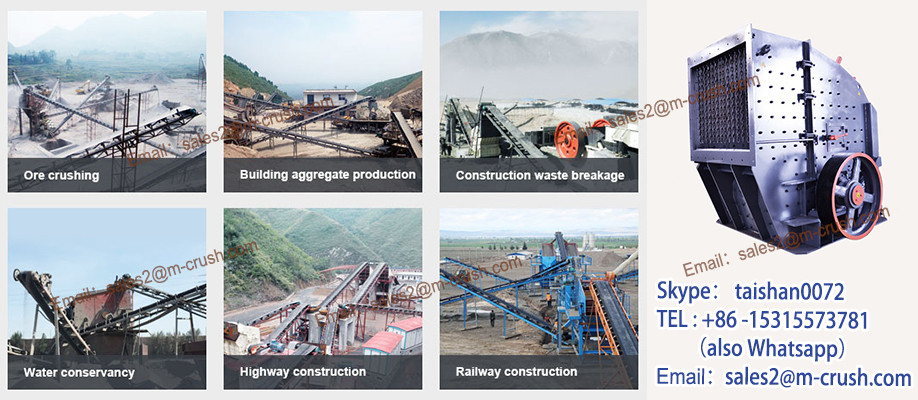

Project Case

Project Case

Zhejiang 200tph limestone crushing production line

The company is the best planning stone factory in the local, which is visited many times by the local government delegation. Customers do not have stone factory operating experience, but taking into account the local good stone market, finally they purchase equipment for rock crushing, mainly supply local mixing station. Main equipment: PE1000*1200 jaw crusher (1 set), PFW1315III impact crusher (2 sets). etc.

Working time: 8 hour; Feeding material: limestone, 700mm below; Output size: 10-31.5mm, 5-10mm, 0-5mm.

Equipment configuration

PE1000*1200 jaw crusher(1 unit)

Equipment configuration

PFW1315III impact crusher (2 sets)

Equipment configuration

Vibrating screen (2 unit)

Customer Feedback

I asked a lot of peer expert to advise configuration issues because firstly get into gravel industry. Professional expert is very sure that Factory direct prices industrial aggregate crushers for sale industrial company provide for our production line, Factory direct prices industrial aggregate crushers for sale product is made-to-measure according to our stone and capacity, which make us use it at ease. This year we have a good local sand machine market and policy support, so we order sand making machine again, another reason is that we trust Factory direct prices industrial aggregate crushers for sale s quality and service.

Mr Song, chairman of the company

PE jaw crusher

91.8% Response Rate

PFW impact crusher

91.8% Response Rate

VSI sand making machine

91.8% Response Rate

Packing & Delivery

Factory direct prices industrial aggregate crushers for sale is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices. Our products have been sold to 120 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.

Recent development includes the MTW series mill, vertical mill, Hydraulic impact crusher,Track mounted crusher, PEW series jaw crusher, etc. Deeply believe that the measure of our worth is in the development and innovation of new products, and we are pursuing the Factory direct prices industrial aggregate crushers for sale direction of technology and quality all the way.

Factory direct prices industrial aggregate crushers for sale Factory

Headquarter of Factory direct prices industrial aggregate crushers for sale is located in Shanghai, China and now we have two manufacturing bases as our strong support. One is located in Shanghai about 450,000 square meters, and the other is in Factory direct prices industrial aggregate crushers for sale city, about 600,000 square meters. It takes about one-hour driving from Shanghai to Factory direct prices industrial aggregate crushers for sale city.

Up to now, we have sales and service offices, and distributors in over 20 countries, more and more effective service will be supplied to local customers.

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers request and budget, our experts make efficient, reliable solutions. Following customers order we produce strictly, whats more, before placing the order every customer has the chance to visit Factory direct prices industrial aggregate crushers for sale working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of Factory direct prices industrial aggregate crushers for sale, they are now strategically located home and abroad, working for our customers.

FAQ

FAQBecause the machines of different models, different prices, I need to ask you some details for sending you the more suitable quotation:

1.Which kind of material you are going to crush? (Dolomite; Calcite; Quartz; Basalt; Barite; Feldspar ; Gravel; Bentonite; Gypsum; Granite; Coal; Slag; Pebble; Others ) ?

2. What's the production capacity you want? How many tons or cubic meters per hour?( > 100 TPH > 50 TPH > 30 TPH > 10 TPH > 1 TPH

3.What's the granularity of the final products you need? (in milimeter, micron or mesh)

4. What's the max input size of the material? (In inch,centimeter or milimeter)

We will give you factory price with full specification,so pls leave us an inquiry to know more details about price, packaging shipping and discount.

....

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.Factory direct prices industrial aggregate crushers for sale is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the Factory direct prices industrial aggregate crushers for sale works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. Factory direct prices industrial aggregate crushers for sale The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK