STNP Series Impact Crusher |

BRIEF INTRODUCTION |

|

Sanland STNP Series rock crushing machinery's feature is the unique combination of heavy rotor design, materials selected for good wear resistance and crusher chamber design. This combination has proven revolutionary in improving capacity and product quality and in reducing operating and wear costs. The rotor with high inertiaimproves crushing reduction and provides stability in the process, reducing energy consumption and increasing long-term performance. Higher reduction with fewer crushing stages lowers your capital costs and saves energy. |

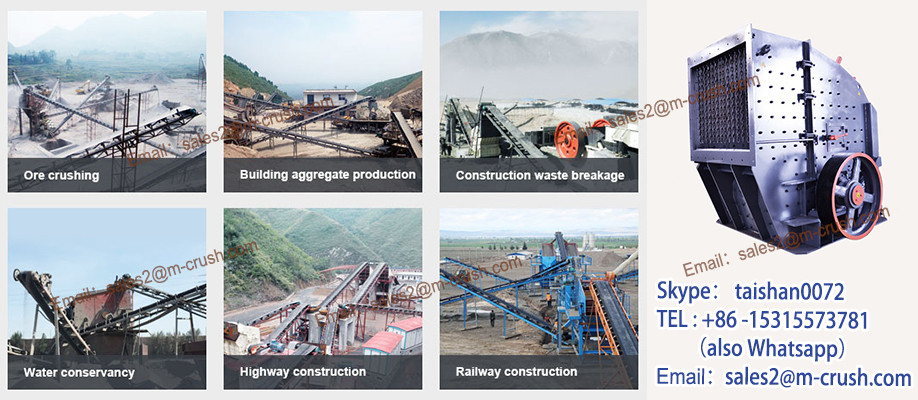

PROJECTS CASES |

PRODUCT FEATURES |

|

1.The Sanland-made cone crusher is a U.S. licensed product with all its spare parts to be interchangeable with the original American Symons cone crushers; 2.Flexible drive, hydraulic adjustment and automatic cavity clearing; 3.Less return materials(able to be reduced to 35%), 55% of regular cone crushers; 4.Grease lubricating system, low consumption and environmentally friendly; 5.No seasonal or temperature constraints. |

PRODUCT PARAMETERS |

| Main dimensions and weights | ||||||

| STNP Model | Crusher complete | Rotor complete | rotor diameter | Rotor width | ||

| Primary range | STNP1313 | 17800kg 39249lbs | 6340kg 13980lbs | 1300mm 51¼" | 1300mm 51¼" | |

| STNP1415 | 21815kg 48102lbs | 8165kg 18004lbs | 1400mm 55 1/8" | 1500mm 59 1/8" | ||

| STNP1620 | 40500kg 89303lbs | 15980kg 35236lbs | 1600mm 63" | 2000mm 78¾" | ||

| STNP2023 | 74230kg 163677lbs | 28280kg 62357lds | 2000mm 78¾" | 2300mm 90 5/8" | ||

| secondary range | STNP1110 | 9250kg 20396lbs | 3065kg 6758lbs | 1100mm 43¼" | 1000mm 39 | |

| STNP1213 | 12780kg 28180lbs | 4850kg 10694lbs | 1200mm 47¼" | 1300mm 51¼" | ||

| STNP1520 | 27100kg 59756lbs | 10400kg 22932lbs | 1500mm 59 1/8" | 2000mm 78¾" | ||

| secondary & tertiary | STNP15 | 16130kg 35567lbs | 6370kg 14046lbs | 1300mm 51¼" | 1500mm 59 | |

| Technical data | |||||

| STNP Model | Feed opening | Maximum feed size | Nominal installed power | Maximum installed power | |

| Primary range | STNP1313 | 1320×1225mm(52"×48¼") | 900mm(35") | 200KW/150hp | 250KW/350hp |

| STNP1415 | 1540×1320mm(60 ×52") | 1000mm(40") | 150KW/350hp | 315KW/400hp | |

| STNP1620 | 2040×1634mm(80¼"×64¼") | 1300mm(51") | 400KW(2×200KW)/ 500HP(2×250hp) | 500KW(2×250KW)/ 700HP(2×350hp) | |

| STNP2023 | 2310×1986mm(91"×78¼") | 1500mm(59") | 1000KW(2×50KW)/ 1300HP(2×650hp) | 1200KW(2×600KW)/ 1600HP(2×800hp) | |

| Secondary range | STNP1110 | 1020×820mm(40¼"×32¼") | 600mm(24") | 160KW/200hp | 200KW/250hp |

| STNP1213 | 1320×879mm(52"×34 ") | 600mm(24") | 200kw/250HP | 250KW/350hp | |

| STNP1520 | 2040×995mm(80¼"×39¼") | 700mm(28") | 400KW(2×200KW)/ 500HP×(2×250hp) | 500KW(2×250KW)/ 700HP(2×350hp) | |

| Secondary & tertiary | STNP15 | 1540×600mm(60 "×24") | 400mm(16") | 315KW/400hp | 355KW/450hp |

SANLAND PROFILE |

|

1. Sanland is a manufacture of all types of cone crusher, Jaw crusher, Impact crusher, Feeder, Screen, ball mill and all Mining equipment and the spare parts. 2. Sanland under license American Symons technology to produce Symons cone crusher (Include 2Ft, 3Ft, 4Ft, 4 1/4Ft, 5 1/2Ft, 7Ft Symons cone crusher) and Gyradisc crusher 36'',48'',66''and So on. Under license No.:85BMSJ/200254MR.only one in China, all the spare parts that we offered is the same as Nordberg Symons Parts. 3. We export full crushing line to Chile, Kazakstan, Congo, Saudi Arabia, and other countries. We offer perfect sales service for customers, we have experience for commissioning the line.

|

PACKING AND SHIPMENT |

|

Packing: Container for machines and spare parts by woonden case or as your demands Shipment: 15-20 working days for New order,7-10 days for Ready goods

|

SANLAND SERVICE |

|

We are committed: to provide the best quality and most efficient first-class after-sale service for the customers. Our company has a professional service team, after the equipments arrive at the scene, our service staff will conduct on-site operational training and operational guidance for the direct users, and our experts can provide you the wear analysis service, maintenance and other considerations to improve quality, reduce costs, guide the user installation, commissioning the machines, and after the machines are normal operation at all, our service staff will return. All the spare parts that the customer needs, we will arrange the spare parts to be reached on the customer site within 24 hours.

|

TRADING PROCESS |

|

|

INQUIRY SERVICE |

|

Your email address and telephone will not be shared or published! Please fill in your need product and your message and do not forget email and/or phone if you like to be contacted. We are the professional machine manufacture in China. I need to ask you some details for sending you the more suitable quotation. 1). feeding material 2). Feeding material MAX. Size (mm) 3). Final mesh size (mm) 4). Capacity (t/h) I hope you can tell me these details. I will give you best quotation ASAP. Thanks. Your satisfaction is our greatest pursuit. We would like to sincerely for your service! We look forward to your inquiry. |

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.rock crushing machinery is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the rock crushing machinery works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. rock crushing machinery The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK