2015 Hot Selling Impact Crusher Plant with Stable Running

Brief Introduction of Impact Crusher Plant

Impact crusher is a new type of crushing equipment with high-efficiency, which has the features of small volume, simple structure, high crushing ratio, low energy consumption, large capacity and even granule. It is a promising equipment. Presently, by practices, its comprehensive function is superior to the cone crusher and the hammer crusher.

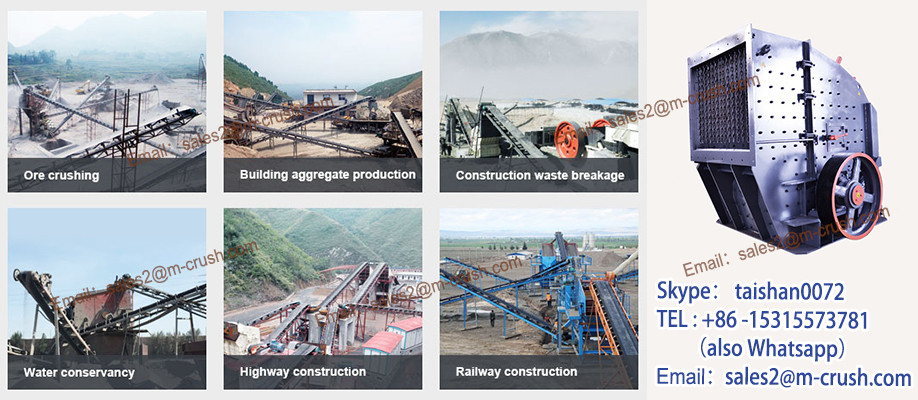

Application of Impact Crusher Plant

It is widely used for crushing ores in mining, highway, railway, construction, energy, cement, chemical industry, etc.

Applied Materials of Impact Crusher Plant

This kind of machine can crush the large, medium and small size materials (granite, limestone, concrete ,etc.) with max feed size less than 500mm and compression strength less than 350Mpa.

Performance Features of Impact Crusher Plant

1. Special structure, high-chromium plate hammer and particular impact liner.

2. High-efficient and energy-saving, hard rocks crushing available.

3. Cubic shaped, simplified crushing process.

4. Granule of the final products can be adjusted.

5. The new type of dedusting device can be configured to eliminate the dust and is beneficial to the environment via technical improvement.

Working Principle and Structure of Impact Crusher Plant

Impact crusher has two series: two-cavity and three-cavity impact crusher. It is a kind of crushing equipment using impact energy to crush materials driven by the motor. When the materials get into the area where the plate hammer effects, by whose high-speed impact function, the crushed materials are thrown to the impact device above the rotor continuously, and then they are rebounded from the impact liner to the effect area of the plate hammer to be crushed again. The materials are repeatedly crushed from big size to small size in the impact cavity. The process goes on until the materials are crushed to required size and then discharged from the down part of the machine.

Technical Parameter of Impact Crusher Plant

> > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > >

Model |

Specification (mm) |

Feeder Opening Size (mm) |

Feeding Size (mm) |

Capacity (t/h) |

Power (kw) |

Overall Dimension (mm) |

Weight (t) |

PF-1007 |

1000×700 |

400×730 |

≤250 |

15-60 |

45 |

2319x1651x2558 |

10.5 |

PF-1010 |

1000×1050 |

400×1080 |

≤300 |

50-90 |

55 |

2319x2001x2558 |

12.5 |

PFV-1210 |

1250×1050 |

400×1080 |

≤300 |

70-130 |

90 |

2582x2053x2809 |

15.8 |

PFV-1214 |

1250×1400 |

400×1430 |

≤300 |

90-180 |

132 |

2582x2403x2809 |

19.8 |

PFV-1315 |

1320×1520 |

860×1520 |

≤350 |

120-250 |

160 |

2930x2761x3053 |

24 |

PFV-1320 |

1320×2000 |

860×2030 |

≤500 |

160-350 |

200 |

3224x3175x2706 |

29 |

Spare Parts of Impact Crusher Plant

Details of Impact Crusher Plant

Production Process of Impact Crusher Plant

Construction Site of Impact Crusher Plant

Product Shipping of Impact Crusher Plant

Certificates of Shibo Company

Clients' Visit

Show of Shibo Company

> > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > >

More about Henan Shibo Mechanical Engineering Co., LTD

1. Enterprise Concepts

• Business Philosophy: “Thought determines development, integrity makes survival”.

• Management Principle: “System first, manager second”.

• Industrial Spirit: “Striving to be stronger, serving the country with industrial development”.

• Industrial responsibility: “Limited resources, unlimited technology”.

• Development Mission: “Technology to create, model for the industry”.

2. Our Service

• Pre-sales

a. Help customers to choose product.

b. Freely send engineers to the working field to plan the installation site and design the best technical production process.

c. Design the special product according to the contract.

• On-sales

a. Inspect every part of machines before production.

b. Deliver goods on schedule according to the contract.

• After-sales

a. Send the engineers to guide the installation.

b. Install and adjust the equipment for customers.

c. Train the operator for customers.

d. We also provide the technical service for our customers after the installation.

e. If there is any problem during the application, our after-sale engineer shall ensure to offer clear solutions within 24 hours or arrive at the working site within 48 hours ASAP.

3. Business Scope

Our main products include:

• Stone crusher series: jaw crusher, impact crusher, cone crusher, etc.

• Mobile crushing station: mobile jaw crusher, mobile impact crusher, mobile cone crusher.

• Sand-making equipment series: VSI-IV sand-maker, PCL sand-maker, sand-washer, etc.

• Beneficiation equipment series: flotation machine, spiral classifier, rotary dryer, etc.

• Grinding mill series: ball mill, raymond mill, etc.

• Feeding and screening equipment series: vibrating screen, vibrating feeder, etc.

• Accessory equipment: belt conveyor, bucket elevator, screw conveyor, etc.

They are widely used in the fields of metallurgy, mine, chemical industry, building materials, coal, refractory materials, ceramic, etc. Besides, our products are also exported to more than 30 countries, such as Uzbekistan, Denmark, Turkey, Vietnam, Nigeria, etc.

> > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > >

Why choose Shibo:

Producing high-quality and reliable machines is always our first priority, because we know that our success depends entirely on the satisfaction of our clients. We never give up quality to save cost, instead we manufacture our machines to supply you the best need.

• We are factory (Not Dealer)

• We have our own factory & land (Not Renting)

• Staff reside in factory (Stable Workforce)

• Perfect pre-sale, on-sale and after-sale services.

In order to give you a responsible and accurate quotation and recommendation of the machine, please inform us of the following information:

• What is the raw materials you are going to crush?

• What is the size of the raw materials?

• What is the final granularity of the materials you are going to achieve?

• What is the production capacity you are going to get?

• What do you want? Only a set of stone jaw crusher, or a complete crushing production line?

More information, please visit our showroom on crushing machine impact crusher rock crushing plant:

http://expocrusher.en.crushing machine impact crusher rock crushing plant.com

> > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > > >

View More? Please click below pictures for more information!

Jaw Crusher Impact Crusher Cone Crusher

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.crushing machine impact crusher rock crushing plant is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the crushing machine impact crusher rock crushing plant works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. crushing machine impact crusher rock crushing plant The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK