New Condition Impact Crusher Wear Parts in Stock

Company Information

We are China's most professional manufacturer of mining crusher.

1. The company's main products include heavy-duty hydraulic gyratory type. Simmons cone type,single-cylinder hydraulic cone type,multi-cylinder hydraulic cone type,jaw type,hammer type,reaction type,double roller type and other series of crusher.

2. And various sand making machines,feeding machines,vibrating screen classifiers and other complete sets of mine mechanical equipment.

3. By means of joint R&D with China University of Mining&Technology,the products have been upgraded continuously and have occupied the main domestic market. It has become vibrating screen classifier supplier in the state-level key construction projects projects.

4. such as Three Gorges Project,Beijing-Shanghai High-speed Railway,Shandong Expressway,Shandong Cement,Hainan High-speed Railway,China's Nuclear Power,etc.

5. The company also actively extends foreign markets and the products are exported to Nigeria. Indonesia,Philippines,South Korea,Laos.Iran and other countries.

Product Pictures

Supply range of DaTong crusher :

1.Vibrating feeder, two types of GZD and ZSW to meet user’s different processing capacity;

2.First crushing: Jaw crusher, or Impact crusher, or cone crusher to meet user’s choise

3.Secondary crushing: fine jaw crusher, or impact crusher, or cone crusher(spring type, spring and hydraulic type, hydraulic type)

4.Vibrating screen, YK series, linear series, DF series

5.Belt conveyor, stationary type, or mobile type

6.Steel structures, such as feed-in and discharge hoppers, stairways, guardrails, maintenance board, steel channel, etc.

7.Electric control cabinet,diesel power generation set for choosing.

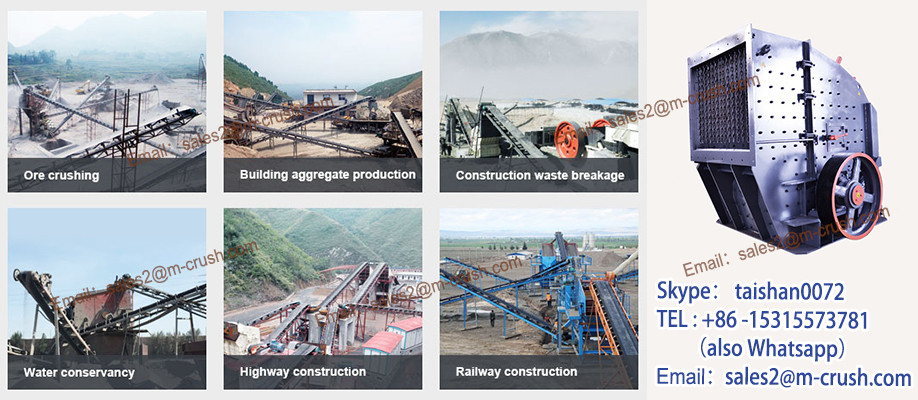

Application

Application: It is widely used n the crushing of ores, expressway, cement, chemical, building and other industries.

Product Description

Operating principle:

Reaction crusher is a crushing machine that uses the striking energy to crush the material.When at work, the rotor runs at a high speed with the drive of electric motor.After being crashed by striking of the board hammer of the rotor when the material comes into the impact zone of the board hammer, the material is crashed again after being threw into the reaction unit, and then it is crashed again after being rebound to impact zone of the board hammer.The process is repeated.The material comes into the first, second, and third reaction cavity to be crushed repeatedly, till the material is crushed to the required granularity, and is discharged from the discharge gate.Adjusting the space between reaction frame and rotor can change the material discharging granularity and material shape.

Chracteristics:

It is applied to the secondary crushing after coarse crusher, can crush the ore of which compressive strength is not more than 320Mpa.It has such advantages as big processing value, fine discharging material, the finished product without innercrack,and etc.

| model |

rotor diameter (mm) |

rotor length (mm) |

maximum feeding material size (mm) |

production capacity(t/h) |

motor power (kw) |

Weight (T) |

| PF-1007 | Φ1000 | 700 | 200 | 25-50 | 55 | 6.04 |

| PF-1010 | Φ1000 | 1000 | 250 | 30-80 | 75 | 9.56 |

| PF-1210 | Φ1250 | 1050 | 300 | 60-120 | 110 | 14.2 |

| PF-1212 | Φ1250 | 1250 | 300 | 80-140 | 132 | 16 |

| PF-1214 | Φ1250 | 1400 | 300 | 100-160 | 132 | 20.2 |

| PF-1310 | Φ1300 | 1050 | 300 | 70-140 | 132 | 21 |

| PF-1315 | Φ1320 | 1500 | 300 | 100-180 | 220 | 22.07 |

| PF-1320 | Φ1300 | 2000 | 300 | 150-250 | 315 | 27.3 |

| PF-2018 | Φ2000 | 1800 | 700 | 300-600 | 250*2 | 66 |

Main Features:

1. Model for the latest products, a wide range of applications, with a compact structure, long service life, high work efficiency.2. Adjustable for easy wear parts, Easy replacement of wear and spare parts3. High capacity, Less costly and Easy to install

4. The machine has a large crushing ratio, uniform product size, simple structure, convenient maintenance, can crush the compressive strength of a variety of materials is not more than 320 MPa, is the first choice for primary crushing equipment.

5. First-class technology, reliable pre-sale customer service quality. The products meet European CE certification standards.

Packaging & Shipping

Packaging Details:

We will load different sizes of packing according to different machine sizes, and the normal packing is in wooden cases (size: L *). If exported to European countries, wood frame will be fumigated. If the container is too tight, we will use the PE film according to the customer's special requirements.

Delivery time:

We will begin producion after receving the advance payment. No matter what size of the products the customer requires, we can deliver the good in two weeks after receving the balance charge.

Our Services

Pre-Sales Service

1, Inquiry and consulting support.

2,Pre-sale service:Freely provide project designing, process designing, choosing suitable equipment for you.

3, View our Factory.Field trips to sell products.

After-Sales Service

1,After acceptance of the equipment, we will draft the construction program and detailed process, and complete the export process

2,After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

Advantages of DaTong Brand of Stone Production Line:

1. Complete stone production line,the Crusher near to turn-key project;

2. Stationary type or mobile type for choosing

3. First class workmanship.Reliable quality with CE approved, reaching to European standard

4.Updating in design and function year by year, Invention technical patent.Forms our own unique design by considering of saving more cost and improve the processing capacity for user’s consideration.

Our Customer

To provide a complete production line crusher, we will send senior engineer to site installation and training machine, and provide a detailed proposal for operation training for customers according to customer's site requirements and application, we will help customers to choose the right equipment, drilling rigs, loaders, trucks, excavators and other equipment.

Engineers exchanges with foreign clients working abroad:

Certificate

FAQ

1.Installation:

If the buyer ask the seller to sent the technicians to guard to install the machines in the site, the buyer should take all the charges for the technicians and pay the saNew Condition Impact Crusher Wear Parts in Stock (30USD each person one day).

2.What about Warranty?

Hi, Ours Warranty is 1 year for whole machinery .

Spare parts . For wear parts, we guarantee the high quality parts for long-term supply for Crusher.

3.Payment Method:

By L/C,D/A,D/P,T/T,Western Union,MoneyGram

4.If you want us recommend a suitable type and best offer for you ,please let us know as follows:

1). You only need one cone crusher or a whole crushing line?(include the feeder,crusher,screen,conveyor and so on)

2).what is the max size of the stone (mm/inch )?

3).what is the output size you need ?

4). What is the stone type? , marble or others ?

5.What could you help me to do for the business ?

Many thanks for your trust , we can provide you with proposal chart for complete production lines Crusher , spot inspection and operator traning according to your demands and the conditions of applied spot , we can help you choose the right equipments ,drilling rig ,loader ,trucks ,excavators and so on .

Contact Us

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.New Condition Impact Crusher Wear Parts in Stock is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the New Condition Impact Crusher Wear Parts in Stock works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. New Condition Impact Crusher Wear Parts in Stock The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK