High eficiency jaw crushers for gravel&stone stationary crushing line

Material information of stone crushing line

Stone crushing production line have two kinds, one is soft stone crushing line, and another is hard stone crushing line, and this time introduce soft stone crushing line, if you need informations about the hard stone crushing line, please fell free to contact me.

Raw materials: soft rock or stone which compressive strength less than 150MPa, such as limestone, dolomite, shale, gypsum, etc, and the hard rock (granite, basalt etc) after weathering.

Capacity: 30-800t/h

Max feeding size: 1000mm

Application: Highway, high railway, hydroelectric dam construction, tailings mechanism sand, mechanism sandstone Quarry, cement and sandstone joint production, abandoned mining recycling, building materials, and chemical industry

Equipment Configuration of stone crushing line :

GZD seriesvibrating feeder + PE series jaw crusher + PF Impact crusher + YK series circular vibrating screen + severalbelt conveyor;

Customer can select dust remove machine or not according to local environment protect requires

The flowing chart of stone crushing line :

Advantages of stone crushing line:

1.Complete stone production line, near to turn-key project;

2.Stationary type or mobile type for choosing

3.First class workmanship

4.Reliable quality with CE approved, reaching to European standard

5.Updating in design and function year by year, forms our own unique design by considering of saving more cost and improve the processing capacity for user’s consideration.

6.Invention technical patent kept.

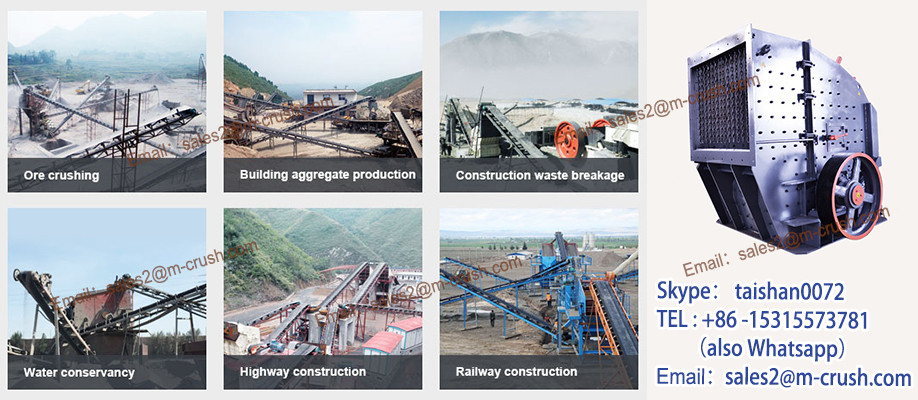

FTM Working Sites

Solutions Information

In order to recommend suitable design for your need stone crushing line, please kindly suggest the answer to my questions below:

1. what is your raw material to be crushed is it soft stone (like limestone, dolomite) or hard stone (like granite, basalt, river stone, etc)? __________

Impact crusher is suitable as secondary crusher for soft stone, while cone crusher is suitable as secondary crusher for hard stone.

2. What is the maximum feed size of your raw material? ____________

3. What are output sizes you want? ____________________

Normally for road construction, it is 0-40mm, while for aggregate, it is 0-20mm.

4. What is per hour capacity you want? ____ ton per hour

5. Are you the end user or will you re-sell the machinery to your clients?

Full service of Fote Machinery

1>.Pre-sale services We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

2>.Sale services Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

3>.After-sale services To establish long term friendship, we will regularly pay return visit to customers.Supplying technique, building design, instruction, installation and debugging for free.

4>.We provide one-year warranty to make sure your machine runs consistently. We always offering lifelong services and provide spare parts for a long term,and repair main parts under right using for free in two years.

Impact Rock Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone.High eficiency jaw crushers for gravel&stone stationary crushing line is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

JHDGFHVB

When the High eficiency jaw crushers for gravel&stone stationary crushing line works, the motor drives the rotor to rotate with high speed, on the rotor where installed the hammers. When the materials get into the area which the hammers effect, under the impact function of the hammer at a high speed, the materials are thrown to the impact device above the rotor continuously. Impact Rock Crusher And then the materials are rebounded from the impact liner to the area where the hammers effects for being recrushed. High eficiency jaw crushers for gravel&stone stationary crushing line The materials from large to small all to be crushed at the impact chamber repeatedly. The process won’t stop till the material are crushed to the required size and then discharged from outlet.

JKKJBLK