Competitive Price Mining Equipment Single Cylinder Hydraulic Cone Crusher

Brief Introduction of Competitive Price Single Cylinder Hydraulic Cone Crusher:

Competitive Price Single Cylinder Hydraulic Cone Crusher adopts the best combination of crushing frequency and eccentricity, so the content of fine crushed products is higher. Therefore, the efficiency of more fine products but less grinding is very significant.The power consumption of crushing and grinding is also reduced greatly.

Perfect combination of high crushing efficiency and highly efficient chamber makes larger capacity than other crushers. More materials are crushed in different layers, so the shape of final product is evenly cubic. Hydraulic insurance, Hydraulic adjustment and method for cleaning chamber make operation easier and maintenance much more convenient. It is easier to realize automation. This series of Competitive Price Single Cylinder Hydraulic Cone Crusher has much less breakdown, the rate of operation is over 85%, so the whole cost is reduced greatly.

1. Materials are crushed into much smaller size, realizing more fine products but less grinding. The crushing capacity in the following process is increased, and the power consumption of system is reduced.

2. Larger capacity and smaller size of final product reduce cyclic load, so the abrasion between the chute of vibrating screen and belt conveyor greatly reduced, and power consumption of belt conveyor is reduced too.

3. Hydraulic Cone Crusher spare parts can be easily changed, so downtime is shortened.

Working Principle of Competitive Price Single Cylinder Hydraulic Cone Crusher

Competitive Price Single Cylinder Hydraulic Cone Crusher Crushing process is completed between the fixed cone and eccentric rotating moving cone. Horizontal axis of Hydraulic Cone Crusher is driven by motor through the V-belt, the horizontal axis drives the eccentric cover by the gear. Eccentric cover makes main shaft rotate to cause eccentricity. Materials enter crushing chamber through upper inlet of crusher, and crushed products are discharged out through the lower outlet.

1.Human design and hydraulic adjustment of discharge outlet saves time and work. Adjustment can be controlled by buttons.

2. Single hydraulic system adjusts main shaft and body, the body can rise and decline integrally to adjust discharge size, so slope of side cylinder and upper frame can be avoided.

3. Working pressure system can be adjusted hydraulically; pressure adjusting system can discharge super hard materials to protect the machine.

4.Spare parts can be changed easily. The rolling mortar wall and cone body combined stably after precise design, and there’s no need to fill again, so time to change spare parts can be saved. Stuffing is not necessary to be filled as the installation of rolling mortar is very stable.

5. Hydraulic pressure of the whole machine is low, so the pressure to hydraulic parts and main engine is also low, hydraulic system is more durable and stable.

6. The size and weight of this machine are relatively small, so installation and transportation are very convenient.

Technical Data of Competitive Price Single Cylinder Hydraulic Cone Crusher

| Model | Diameter (mm) | Capacity (t/h) | Power(kw) | Speed of eccentric shaft(r/min) | weight (t) | Overall Dimension (L×W×H) (mm) | ||

PYB600 |

600 | 65 |

12-25 |

12-25 |

30 |

356 |

5 | 2800×1300×1700 |

PYD600 |

600 | 35 | 3-15 |

5-23 |

30 |

356 |

5.5 |

2800×1300×1700 |

PYB900 |

900 | 115 | 15-50 |

50-90 |

55 | 333 | 10.2 |

3050×1640×2350 |

PYZ900 |

900 | 60 | 5-20 |

20-65 |

55 | 333 | 10.2 |

3050×1640×2350 |

PYD900 |

900 | 40 | 3-13 |

15-50 |

55 | 333 | 10.3 |

3050×1640×2350 |

PYB1200 |

1200 | 145 | 20-50 |

110-200 |

110 |

300 |

24.7 |

4152×2300×2980 |

PYZ1200 |

1200 | 100 | 8-25 |

50-150 |

110 |

300 |

25 | 4152×2300×2980 |

PYD1200 |

1200 | 50 | 3-15 |

18-105 |

110 |

300 |

25.6 |

4152×2300×2980 |

PYB1750 |

1750 | 215 |

25-60 |

280-480 |

160 |

245 |

50.3 |

4870×3800×4192 |

PYZ1750 |

1750 | 185 |

10-30 |

115-320 |

160 |

245 |

50.3 |

4870×3800×4192 |

PYD1750 |

1750 | 85 |

5-15 |

75-230 |

160 |

245 |

50.4 |

4870×3800×4192 |

PYB2200 |

2200 | 300 |

30-60 |

590-1000 |

260-280 |

220 |

80 | 7705×3430×4852 |

PYZ2200 |

2200 | 230 | 10-30 |

200-580 |

260-280 |

220 |

80 | 7705×3430×4852 |

PYD2200 |

2200 | 100 | 5-15 |

120-340 |

260-280 |

220 |

81.4 |

7705×3430×4852 |

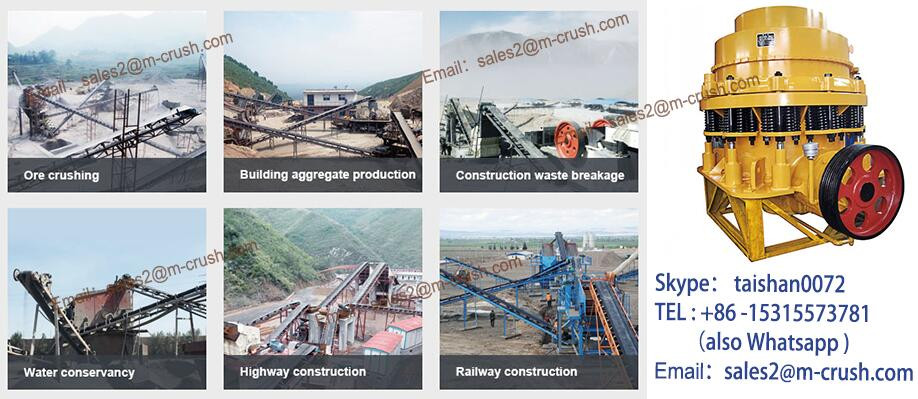

Latest Image of Competitive Price Single Cylinder Hydraulic Cone Crusher

Competitive Price Mining Equipment Single Cylinder Hydraulic Cone Crusher is the orginal cone crusher, which internationly advanced and longtime popular.

Single Cylinder Hydraulic Cone Crusher, hydraulic cone crusher and symons cone crusher concentrates on the high-frequency, optimization of cavity and reasonable impact, Single Cylinder Hydraulic Cone Crusher based on conception of laminated crushing principle and more crushing and less grinding, Competitive Price Mining Equipment Single Cylinder Hydraulic Cone Crusher heavily.Single Cylinder Hydraulic Cone Crusher is widely used to crush all kinds of ores and rocks with medium hardness and above, metalliferous and non-metalliferous ores, cement, construction and sand.Single Cylinder Hydraulic Cone Crusher The materials can be iron stone, non-ferrous metal ore, granite, limestone, quartzite, sandstone, cobble, etc.

HSGDJDHF

Single Cylinder Hydraulic Cone Crusher , sometimes called gyratory cone crushers. Single Cylinder Hydraulic Cone Crusher crush rock between two conical surfaces called the mantle (lower movable surface) and the concave liners above. These surfaces do the actual crushing and are constructed of high manganese steel. Competitive Price Mining Equipment Single Cylinder Hydraulic Cone Crusher can be used in a primary crushing role but are typically seen more often in a secondary or tertiary position. There are two types of cone crushers with respect to the pay product size: standard head and fine head cone crushers. Fine head cone crushers have a reduced-size opening and so can't take as large of feed material but can produce a finer output product. Competitive Price Mining Equipment Single Cylinder Hydraulic Cone Crusher action is achieved by the eccentric movement of the lower portion of the main shaft. The mantle is connected to this main shaft. Single Cylinder Hydraulic Cone Crusher The gyrating action of the main shaft causes the gaps between the mantle and liners to change dimension and perform the actual crushing.

JHEDEF