Introduction:

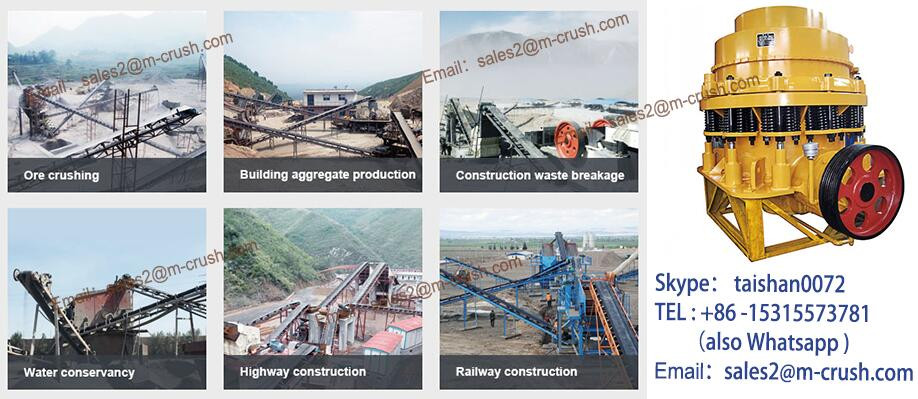

The DMG Hydraulic Cone Crusher series is the most recent Cone Crusher to be designed by DongMeng,and incorporates the latest technology from Finland to improve crushing action and production. The machines teatures include,large output capacity,with consistently good product shape. The discharge setting adjustment is easily made,and replacement of wear parts is quick,thereby reducing downtime.these efficient machines are widely used in medium and fine crushing applications.

Principles:

- The large diameter main shaft and heavy duty mainframe ensures a sturdy and durable machine.Multiple available cavities,variable stroke,and multi swing frequency,offer different discharging opening sizes for various product ranges.

- Adjustment of CCS is made quickly and hydraulically,and these machines offer a higher rate of production when compared to other similar sized units.

- The low head design profile,minimal maintenance requirement,consistent reliability,and overall light weight factor makes these machines ideally suited for mobile crushing plant configuration.

Best in Agency was introduced in the year 2012 and since we are thriving under the leadership of Owner Mr. Benabdallah Brahim, who has more than 15 years of experience. We are located in Algeria and owing to a huge B2B directory base, we provide solutions to clients in African countries, The Middle East, South Asia, China and in near future also India (Construction and Mining).

Maximized Profits

Without tampering integrity, our pricing policy is formulated suiting to budget specifications of clients. We have been a great mediator to carry out lucrative deals for both the entities. Our associations with quality-oriented manufacturers and vendors in industry have helped us to bring forth exclusive collection of apparels. We ensure our dependability by serving our clients with error-free pre-production approval, sampling production control and timely delivery management.

Quality Management System

- Not only product specific, our quality management system encompasses every corporate process that affects quality on either ground. To maintain our quality promises, we do the following.

- After stringent hiring process, we have assembled team of specialized quality controllers.

- We do not believe in making mistakes. Thus, we adopt “do it right the first time” policy and implement “plan-do-check-act” approach.

- Evaluation and inspection of products.

- Keep our staff updated about new quality control procedures and train them accordingly.

- Keep ourselves aware of international approved, standards, methods & guidelines.

Gaining a reputable niche in a short span of time would not have been possible without our unique work methodologies and dedication to serve with world class assistance. Further, what makes us stand apart from other Buying Agents in industry are as follows :

- Well established and reliable sourcing network

- Ethical Business Practices

- Affordable & Dependable

- Perfect search as per buyers’ stipulations

-

Integrated work culture

| Copyright © 2016. BEST IN AGENCY. All Rights Reserved | Product Ranking Service by Opal Infotech |

|---|

Single Cylinder Hydraulic Mini Cone Crusher Available at Low Rate is the orginal cone crusher, which internationly advanced and longtime popular.

Single Cylinder Hydraulic Cone Crusher, hydraulic cone crusher and symons cone crusher concentrates on the high-frequency, optimization of cavity and reasonable impact, Single Cylinder Hydraulic Cone Crusher based on conception of laminated crushing principle and more crushing and less grinding, Single Cylinder Hydraulic Mini Cone Crusher Available at Low Rate heavily.Single Cylinder Hydraulic Cone Crusher is widely used to crush all kinds of ores and rocks with medium hardness and above, metalliferous and non-metalliferous ores, cement, construction and sand.Single Cylinder Hydraulic Cone Crusher The materials can be iron stone, non-ferrous metal ore, granite, limestone, quartzite, sandstone, cobble, etc.

HSGDJDHF

Single Cylinder Hydraulic Cone Crusher , sometimes called gyratory cone crushers. Single Cylinder Hydraulic Cone Crusher crush rock between two conical surfaces called the mantle (lower movable surface) and the concave liners above. These surfaces do the actual crushing and are constructed of high manganese steel. Single Cylinder Hydraulic Mini Cone Crusher Available at Low Rate can be used in a primary crushing role but are typically seen more often in a secondary or tertiary position. There are two types of cone crushers with respect to the pay product size: standard head and fine head cone crushers. Fine head cone crushers have a reduced-size opening and so can't take as large of feed material but can produce a finer output product. Single Cylinder Hydraulic Mini Cone Crusher Available at Low Rate action is achieved by the eccentric movement of the lower portion of the main shaft. The mantle is connected to this main shaft. Single Cylinder Hydraulic Cone Crusher The gyrating action of the main shaft causes the gaps between the mantle and liners to change dimension and perform the actual crushing.

JHEDEF