Product Description

Single cylinder hydraulic cone rock crusher

Single cylinder hydraulic cone rock crusher is a new generation crusher which is professional for very hard stone crushing with high efficiency and lowest wearing. It is professional for hard stone, river stone crushing, metal ore mining etc.

New design Packing & Delivery

Packing & DeliveryPacking.

We arrange export standard packing. Fumigation wooden box, and water-proof plastic colth.

Main parts are nude by container.

Delivery.

We can arrange delivery according to customers requirement, but 15 workdays at least.

Delivery terms subject to the stipulations of intercoms 2000

Parameters

Parameters| Model | Cavity | Max inlet size(mm) | Min outlet size (mm) | Max loading power(KW) |

| CSG420 | S1(Extra Coarse) |

240 | 22 | 90 |

| S2(Medium Coarse) | 200 | 19 | ||

| CHG420 | H1(Fine) | 135 | 10 | |

| H2(Medium Fine) | 65 | 8 | ||

| H3(Extra fine) | 38 | 4 | ||

| CSG430 | S1(Extra Coarse) | 360 | 25 | 160 |

| S2(Medium Coarse) | 300 | 22 | ||

| S3(Coarse) | 235 | 19 | ||

| CHG430 | H1(Fine) | 185 | 13 | |

| H2(Medium Fine) | 90 | 10 | ||

| H3(Extra fine) | 50 | 6 | ||

| CSG440 | S1(Extra Coarse) | 450 | 35 | 250 |

| S2(Medium Coarse) | 400 | 29 | ||

| S3(Coarse) | 300 | 25 | ||

| CHG440 | H1(Fine) | 215 | 16 | |

| H2(Medium Fine) | 110 | 13 | ||

| H3(Extra fine) | 70 | 8 | ||

| CSG660 | S1(Extra Coarse) | 560 | 41 | 315 |

| S2(Medium Coarse) | 500 | 38 | ||

| CHG660 | H1(Fine) | 275 | 16 | |

| H2(Medium Fine) | 135 | 16 | ||

| H3(Extra fine) | 65 | 13 | ||

| CHG870 | H1(Fine) | 300 | 22 | 520 |

| H2(Medium Fine) | 155 | 19 | ||

| H3(Extra fine) | 80 | 10 | ||

| CHG890 | H1(Fine) | 370 | 25 | 750 |

| H2(Medium Fine) | 195 | 22 | ||

| H3(Extra fine) | 85 | 10 |

Capacity of S cavity and H cavity hydraulic cone crusher

Notes: S1: Extra coarse; S2: Middle Coarse; S3: Coarse

Notes: 1. H1: Fine; H2: Middle Fine; H3: Extra Fine. 2. This production capacity table can be used for HPG cone crusher selection as a preliminary tool. The data in the table are based on material density 1.6t/m³, measurement results by "moment" sampling; If the feeding material has more middle and fine size in closed cycle, the capacity can be increased by 15%-30%.

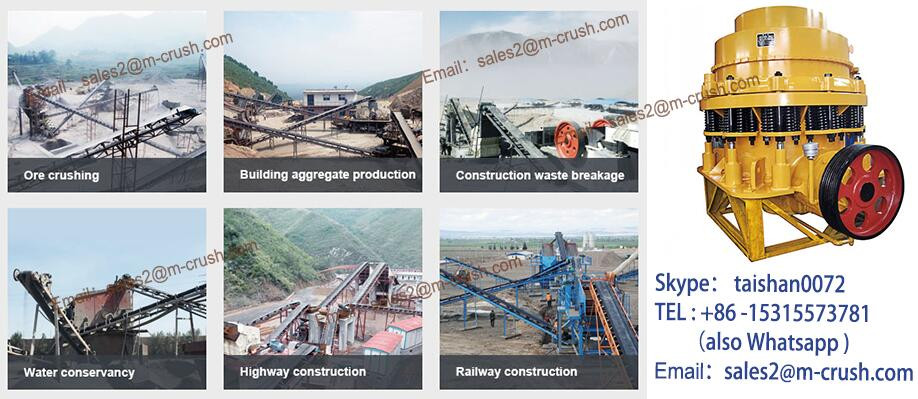

Working site

Advantages

AdvantagesFloating axis.

It is is very easy to adjust the outlet. The autlmatic system can adjust the outlet in working, so you don't need to stop working to adjust.

Steep cone.

Crushing cone is 53-56 degree, so it is deep, and crush more times, better layer crushing effect. The water contents have little affect on the capacity.

Stable-capacity liner design.

The crushing liner can crush the same capacity from beginning to the worklife end. So the total capacity can increase 15%, liner work life increase 6%.

Complete automatic hydraulic hard rock crusher cone crusher is the orginal cone crusher, which internationly advanced and longtime popular.

Single Cylinder Hydraulic Cone Crusher, hydraulic cone crusher and symons cone crusher concentrates on the high-frequency, optimization of cavity and reasonable impact, Single Cylinder Hydraulic Cone Crusher based on conception of laminated crushing principle and more crushing and less grinding, Complete automatic hydraulic hard rock crusher cone crusher heavily.Single Cylinder Hydraulic Cone Crusher is widely used to crush all kinds of ores and rocks with medium hardness and above, metalliferous and non-metalliferous ores, cement, construction and sand.Single Cylinder Hydraulic Cone Crusher The materials can be iron stone, non-ferrous metal ore, granite, limestone, quartzite, sandstone, cobble, etc.

HSGDJDHF

Single Cylinder Hydraulic Cone Crusher , sometimes called gyratory cone crushers. Single Cylinder Hydraulic Cone Crusher crush rock between two conical surfaces called the mantle (lower movable surface) and the concave liners above. These surfaces do the actual crushing and are constructed of high manganese steel. Complete automatic hydraulic hard rock crusher cone crusher can be used in a primary crushing role but are typically seen more often in a secondary or tertiary position. There are two types of cone crushers with respect to the pay product size: standard head and fine head cone crushers. Fine head cone crushers have a reduced-size opening and so can't take as large of feed material but can produce a finer output product. Complete automatic hydraulic hard rock crusher cone crusher action is achieved by the eccentric movement of the lower portion of the main shaft. The mantle is connected to this main shaft. Single Cylinder Hydraulic Cone Crusher The gyrating action of the main shaft causes the gaps between the mantle and liners to change dimension and perform the actual crushing.

JHEDEF