Single cylinder basalt crushing hydraulic cone crusher

DESCRIPTION

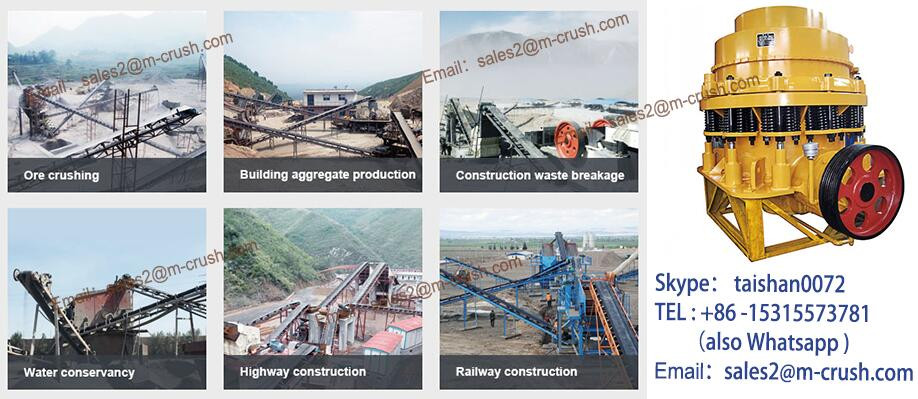

GPY Series Single Cylinder Hydraulic Cone Crusher is one of advanced cone crusher in China, which is developed and manufactured by our company. The machine is one kind of high-class product combined with mechanical technology, electrical technology, hydraulic technology and advanced crushing technology. The machine adopts high strength casting-steel frame, alloy forging main shaft and high precision arc-shaped spiral gear driving structure, combined with multi-chambers selection and automation control system, which fulfills the performance and advantages. It can be widely used in secondary and fine crushing work for all kinds of hard materials and rocks to meet customers' various needs for crushing.

STRUCTURE FEATURES

High Productivity

High ProductivityCombined with optimal crushing chamber, reasonable eccentricity, optimal swing frequency and laminating crushing principle, the machine has a large throughput capacity, high productivity, good products shape and low energy consumption.Automation

Automation control system can achieve the overloading protection, iron-passing protection, and function of constant-chamber without effect of liner-wearing, can also constantly monitor these conditions such as oil temperature, oil flow, oil pressure motor load and discharge opening size, etc., which ensure the machine work stably.High loading Capacity

Optimization design of strong frame construction, two-ends structure (simple support beam) main shaft, unique hydrodynamic lubrication design of copper bush, smart and reliable overload protection system, which ensure the machine have long-term and stable working under extremely bad conditions such as hard rock crushing.Wide Applicability

There are two types of the cone crusher: standard type and short head type. There are several of chambers can be chosen for each type. Different chambers can be changed by ECC. The adjusting of products' classifying can be achieved by adjusting the driving shaft speed to maximize the equipment's value.Low Running Noise and Low Vibration

The driving structure of high precision arc-shape spiral gear has advantages of low running noise, high driving ratio and long durability. Low vibration itself and flexibility supporting of the steel structure ensure minimum vibration (which is caused by transmission from machine to foundation) and low foundation cost.Low Installation Cost

GPY200(s) and GPY300(s) cone crusher's advanced compound cup-type piston design has advantage of low installation height and the integral steel base frame ensure easy installation, short time-cost and minimum installation cost. Low running cost

The liner use ratio and durability can be increased by special crushing chamber, liner structure and liner material. The standard positive pressure dustproof system ensures pure lubrication oil all the time, which extends the using time and low the cost of labor because by less frequent lubrication oil change. Most of the parts can be disassembled in top and side, which is safe, convenient and efficient. TECHNICAL SPECIFICATIONS

• Secondary Crushing(GPY100s,GPY200s,GPY300s)

| Model | Ecc (mm) |

Feed Opening (mm) |

Max. Motor Power (kw) |

CSS(mm) / Throughput Capacity(t/h) | |||||

| C | EC | 25mm | 30mm | 35mm | 40mm | 45mm | |||

| GPY100S | 20 | 250 | 90 | 115-125 | 140-150 | 155-175 | 165-195 | 180-210 | |

| 25 | 180-190 | 195-215 | 205-225 | ||||||

| GPY200S | 25 | 330 | 160 | 165-215 | 185-235 | 205-255 | 225-275 | ||

| 32 | 225-275 | 265-315 | 275-345 | ||||||

| GPY300S | 32 | 380 | 250 | 350-390 | 370-410 | 390-430 | |||

| 40 | 440-490 | 470-520 | |||||||

Remarks: C=Coarse EC=Extra Coarse

The above capacity of listed crusher is based on the rock with bulk density 1.6t/m³. The capacity will be affected by many factors such as selected eccentricity, crushing ratio, material hardness, feed particle size composition, moisture and slit content etc. For more information in details please contact us.

• Fine Crushing(GPY100,GPY200,GPY300)

| Model | Ecc (mm) |

Feed Opening (mm) |

Max. Motor Power (kw) |

CSS(mm) / Throughput Capacity(t/h) | |||||||||||

| EF | F | MF | M | C | EC | 8mm | 10mm | 15mm | 20mm | 25mm | 30mm | 35mm | |||

| GPY100 | 20 | 40 | 50 | 100 | 130 | 150 | 90 | 45-50 | 45-50 | 65-75 | 90-100 | ||||

| 25 | 50-60 | 70-85 | 100-115 | ||||||||||||

| GPY200 | 25 | 70 | 130 | 210 | 160 | 85-105 | 105-125 | 125-150 | 155-175 | 180-205 | |||||

| 32 | 135-155 | 165-185 | 185-215 | ||||||||||||

| GPY300 | 32 | 60 | 100 | 130 | 180 | 260 | 250 | 100-120 | 110-140 | 155-185 | 185-215 |

220-250 | 255-285 | 290-320 | |

| 40 | 140-160 | 195-225 | 235-265 | 280-310 | 315-345 | ||||||||||

Remarks: EF=Extra Fine F=Fine MF=Medium Fine M=Medium C=Coarse EC=Extra Coarse

The above capacity of listed crusher is based on the rock with bulk density 1.6t/m³. The capacity will be affected by many factors such as selected eccentricity, crushing ratio, material hardness, feed particle size composition, moisture and slit content etc. For more information in details please contact us.

GRADATION CURVES• Secondary Crushing(GPY100s,GPY200s,GPY300s)

• The figure on the curves are for the discharging opening size and analysis of square hole.

• The capacity is related to feed particle size, material hardness, material cleanness, humidity and crushing cavity etc.

• Fine Crushing(GPY100,GPY200,GPY300)

• The figure on the curves are for the discharging opening size and analysis of square hole.

• The capacity is related to feed particle size, material hardness, material cleanness, humidity and crushing cavity etc.

• Secondary Crushing(GPY500s)

Remarks: EC=Extra Coarse

• Fine Crushing(GPY500,GPY800,GPY1000)

Remarks: EEF=Extra Extra Fine EF=Extra Fine EFX=Extra Fine Xtra F=Fine MF=Medium Fine M=Medium C=Coarse

MC=Medium Coarse EC=Extra Coarse

The above capacity of listed crusher is based on the rock with bulk density 1.6t/m³. The capacity will be affected by many factors such as selected eccentricity, crushing ratio, material hardness, feed particle size composition, moisture and slit content etc. For more information in details please contact us.

GRADATION CURVES• Secondary Crushing(GPY500s)

• The figure on the curves are for the discharging opening size and analysis of square hole.

• The capacity is related to feed particle size, material hardness, material cleanness, humidity and crushing cavity etc.

• Fine Crushing(GPY500,GPY800,GPY1000)

• The figure on the curves are for the discharging opening size and analysis of square hole.

• The capacity is related to feed particle size, material hardness, material cleanness, humidity and crushing cavity etc.

SPARE PART CENTER

SPARE PART CENTER COMPANY HISTORY

COMPANY HISTORY

-

Year 1958

Established the iron industry community, engaged in repairing and machining business of agricultural machinery and mining machinery. -

Year 1989

Developed the first vertical shaft impact crushing in China, obtained the excellence award of "the new products of international mining equipment" and began to offer the crushing equipment for the client. -

Year 1996

The company has the ability of R&D and manufacturing in Jaw Crusher, Impact Crusher, Cone Crusher, Hammer Crusher, Roller Crusher, Vibrating Screen, Conveyor and Mills. -

Year 2004

Company restructuring and established Luoyang Dahua Heavy Type Machinery Co., Ltd., then continue introduce the international advanced technology of Hydraulic Cone Crusher, Jaw Crusher, Vibrating Feeder, Vibrating Screen and etc. -

Year 2009

The company moved into an area of 190000 square meters of Luolong science and Technology Park, an annual production capacity of 100000 tons of mining machinery manufacturing and established the wear-resistant materials company, refabrication and leasecompany, automation product company, has the matching ability of complete industrial chain. -

Now

Now, we Single cylinder basalt crushing hydraulic cone crusher on the products and technology development of crushing and grinding machinery. Continue offering the professional solution plan of complete crushing and grinding system.

OUR ADVANTAGE

OUR ADVANTAGE

Single cylinder basalt crushing hydraulic cone crusher

Well Equipped Strict Standard DAHUA is well equipped with various kinds of processing machinery , there are about 520 sets high quality process and inspect equipment including lathe , mill , plane , grind , bore , drill , forge , cut and weld equipment . High quality manufacturing and processing ability to cast , rivet weld , process , heat treatment , shot blasting , assemble , paint spraying and test etc . DAHUA set up strict testing standard system above ordinary standard , each process is carried out strictly by detail operating standard include steel plate cut stock to assemble and test machine , each machine must be tested strictly before delivering to ensure the high product quality.

1. Perfect Marketing Performance

1).Complete crushing and screening production line with capacity below 3000t/h

2).Mobile crushing and screening plant with capacity below 800t/h

3).Steel slag recycle production line with capacity of 300-2000 thousand tons per year

4).Construction waste recycle production line

2. Company Certificate and Honor

1).ISO Certificate

2).CE Certificate

3).Henan Province Technology Center

4).China Famous Brand

3. Research and Development Ability

1).Four research and development base

2).80 technical researchers

3).cooperate with international advanced crushing manufacturers

4).Established

5).EstablishedIndustrial Standard

6).Established

7).Established

8).60 Technical Patent in crushing and grinding machinery

4. Equipment and Quality

1).520 sets high quality process and inspect equipment

2).Strict testing standard system

3).ISO standard quality system

Welcome to luoyang dahua heavy machinery co., LTD.

Single cylinder basalt crushing hydraulic cone crusher is the orginal cone crusher, which internationly advanced and longtime popular.

Single Cylinder Hydraulic Cone Crusher, hydraulic cone crusher and symons cone crusher concentrates on the high-frequency, optimization of cavity and reasonable impact, Single Cylinder Hydraulic Cone Crusher based on conception of laminated crushing principle and more crushing and less grinding, Single cylinder basalt crushing hydraulic cone crusher heavily.Single Cylinder Hydraulic Cone Crusher is widely used to crush all kinds of ores and rocks with medium hardness and above, metalliferous and non-metalliferous ores, cement, construction and sand.Single Cylinder Hydraulic Cone Crusher The materials can be iron stone, non-ferrous metal ore, granite, limestone, quartzite, sandstone, cobble, etc.

HSGDJDHF

Single Cylinder Hydraulic Cone Crusher , sometimes called gyratory cone crushers. Single Cylinder Hydraulic Cone Crusher crush rock between two conical surfaces called the mantle (lower movable surface) and the concave liners above. These surfaces do the actual crushing and are constructed of high manganese steel. Single cylinder basalt crushing hydraulic cone crusher can be used in a primary crushing role but are typically seen more often in a secondary or tertiary position. There are two types of cone crushers with respect to the pay product size: standard head and fine head cone crushers. Fine head cone crushers have a reduced-size opening and so can't take as large of feed material but can produce a finer output product. Single cylinder basalt crushing hydraulic cone crusher action is achieved by the eccentric movement of the lower portion of the main shaft. The mantle is connected to this main shaft. Single Cylinder Hydraulic Cone Crusher The gyrating action of the main shaft causes the gaps between the mantle and liners to change dimension and perform the actual crushing.

JHEDEF