Best performance Hard Rock Crusher PF series impact crusher With Superior Quality

Introduct of Impact Crusher

PF series crushing mill machinery It is widely applied in mining, transportation, energy, construction and chemical industry. Impact crushers are ideal choice for crushing and screening. This impact crusher machine features reasonable structure, high productivity, easy operation and maintenance and safe performance. The most outstanding advantage of the impact crusher is that its finished powder is in good, cubic shape and without tensility and cranny.

Features of Impact Crusher

1. High reduction ratio and crushing efficiency;

2. No-board connection; the blow bar with high chrome (high chromed blow bar).

3. Impact plate with a special shape.

4. Crushed product with cubical shape.

5. Easy maintenance and reliable operation.

Working principle of Impact Crusher

This impact crusher machine crushes materials with impact force. When the materials enter the blow bar area, they are crushed due to the high-speed impact of the blow bar and are thrown to the impact plates on the rotor for secondary crush. Then the materials will be shot back to the blow bar again for the third crush. This process repeats until the materials are crushed to the required size and discharged from the lower part of the machine. The size and shape of the finished powder can be changed by adjusting the gap between the impact rack and rotor support. The impact crusher machine employs self-weigh security device in its back frame. When other objects enter the impact cavity, they will be forced out of the machine by the impact rack in the front and back of the machine.

Technical Parameter

Type |

Spec. |

Feeder Opening(mm) |

Feeding Size (mm) |

Crushing |

Motor |

Weight |

PF-1007 |

Φ1000×700 |

400×730 |

300 |

35-50 |

37-55 |

9.45 |

PF-1010 |

Φ1000×1050 |

400×1080 |

350 |

50-80 |

55-75 |

12 |

PF-1210 |

Φ1250×1050 |

400×1080 |

350 |

70-120 |

110-132 |

14 |

PF-1214 |

Φ1250×1400 |

400×1430 |

350 |

80-160 |

132-160 |

18.58 |

PF-1315 |

Φ1320×1500 |

860×1520 |

500 |

160-260 |

180-260 |

24.2 |

Product show

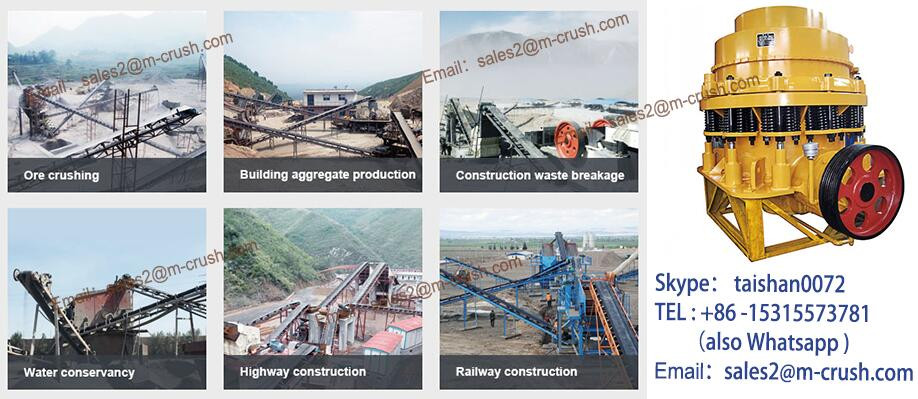

Application of Impact Crusher

Delivery site

packing & shipping

Packaging Detail:

- Packing Requirement: Standar Containers

- Inner Packing: Product wrapped by PP-Bubble

- Outer Packing: Load container, Spare Parts in wooden case

- Storage Requirement: waterproof, put in the flat ground

Transportation:

- These machines are processed to be rustproof and moisture proof before delivery.

- Large mainframes are in nude, while small spare parts and motors are in wooden boxes.

- All items are in bulk or containers, details will be negotiated by both parts afterwards

services

Pre-sale services:

(1) device model choice.

(2) According to customer's special requirements, design and manufacture of products.

(3) Training technical personnel for clients.

(4) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

Sales tracking :

(1) product acceptance.

(2) to help customers develop construction programs.

After-sale services :

(1) free to assign a dedicated service personnel, arriving at the scene and guiding customers' installation.

(2) equipment installation.

(3) on-site training of operators.

(4) complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.

Contact us

If you are interested in our products,please feel free to contact with me: Zhengzhou General Mining Machinery Co.,Ltd. Contact with Ms.Alice Mob/Wechat/Whatsapp: 0086-13213128757 Office Add: Room 901, Building 15, Enterprise Park, No.228, West 4th Ring Road, High-Tech District, Zhengzhou, Henan, China.

Note: Our company bank information will never be changed,once someone notice you to change, please telephone to confirm in case be cheated by strangers.

best performance Hard Rock Crusher PF series impact crusher With Superior Quality is the orginal cone crusher, which internationly advanced and longtime popular.

Single Cylinder Hydraulic Cone Crusher, hydraulic cone crusher and symons cone crusher concentrates on the high-frequency, optimization of cavity and reasonable impact, Single Cylinder Hydraulic Cone Crusher based on conception of laminated crushing principle and more crushing and less grinding, best performance Hard Rock Crusher PF series impact crusher With Superior Quality heavily.Single Cylinder Hydraulic Cone Crusher is widely used to crush all kinds of ores and rocks with medium hardness and above, metalliferous and non-metalliferous ores, cement, construction and sand.Single Cylinder Hydraulic Cone Crusher The materials can be iron stone, non-ferrous metal ore, granite, limestone, quartzite, sandstone, cobble, etc.

HSGDJDHF

Single Cylinder Hydraulic Cone Crusher , sometimes called gyratory cone crushers. Single Cylinder Hydraulic Cone Crusher crush rock between two conical surfaces called the mantle (lower movable surface) and the concave liners above. These surfaces do the actual crushing and are constructed of high manganese steel. best performance Hard Rock Crusher PF series impact crusher With Superior Quality can be used in a primary crushing role but are typically seen more often in a secondary or tertiary position. There are two types of cone crushers with respect to the pay product size: standard head and fine head cone crushers. Fine head cone crushers have a reduced-size opening and so can't take as large of feed material but can produce a finer output product. best performance Hard Rock Crusher PF series impact crusher With Superior Quality action is achieved by the eccentric movement of the lower portion of the main shaft. The mantle is connected to this main shaft. Single Cylinder Hydraulic Cone Crusher The gyrating action of the main shaft causes the gaps between the mantle and liners to change dimension and perform the actual crushing.

JHEDEF