We are China's most professional manufacturer of mining crusher.

1. The company's main products include heavy-duty hydraulic gyratory type. Simmons cone type,single-cylinder hydraulic cone type,multi-cylinder hydraulic cone type,jaw type,hammer type,reaction type,double roller type and other series of crusher.

2. And various sand making machines,feeding machines,vibrating screen classifiers and other complete sets of mine mechanical equipment.

3. By means of joint R&D with China University of Mining&Technology,the products have been upgraded continuously and have occupied the main domestic market. It has become vibrating screen classifier supplier in the state-level key construction projects projects.

4. such as Three Gorges Project,Beijing-Shanghai High-speed Railway,Shandong Expressway,Shandong Cement,Hainan High-speed Railway,China's Nuclear Power,etc.

5. The company also actively extends foreign markets and the products are exported to Nigeria. Indonesia,Philippines,South Korea,Laos.Iran and other countries.

Product Pictures

More Products

Supply range of DaTong crusher :

1.Vibrating feeder, two types of GZD and ZSW to meet user’s different processing capacity;

2.First crushing: Jaw crusher, or Impact crusher, or cone crusher to meet user’s choise

3.Secondary crushing: fine jaw crusher, or impact crusher, or cone crusher(spring type, spring and hydraulic type, hydraulic type)

4.Vibrating screen, YK series, linear series, DF series

5.Belt conveyor, stationary type, or mobile type

6.Steel structures, such as feed-in and discharge hoppers, stairways, guardrails, maintenance board, steel channel, etc.

7.Electric control cabinet,diesel power generation set for choosing.

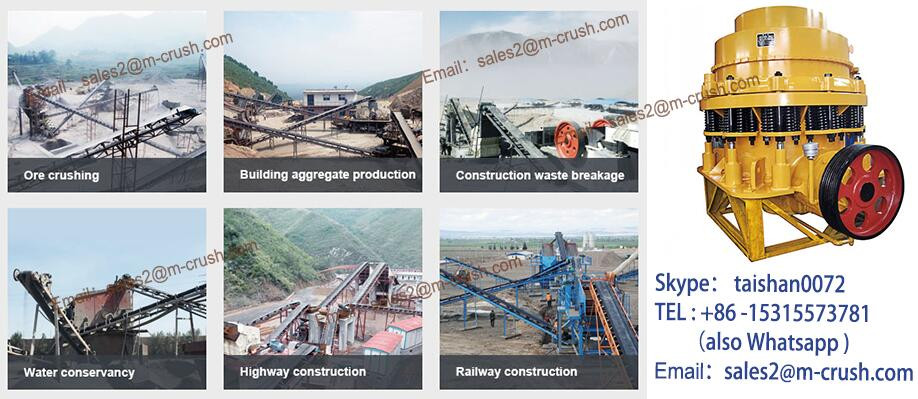

Application

Application: It is applied to fine crushing of various material of which compressive strength is less than or equal to 320Mpa, is applied to relatively small feeding material granularity and relatively small discharging gate, and is fitted for the secondary crushing.

SD-DaTong provides a complete line of stone production; the output is widely used in road, bridge, house, high building,railway, highway, water project as the type of construction material, such as aggregate, foundation stone, etc.

Product Description

Purpose:

This machine is suitable for processing gravels,ores,slags and construction waste,and used for second,three or four level crushing of stones and slags.

Working principle:

The motor drives rotation of eccentric locking collar through belt pulley and gear.And,the spindle shall drive deflection of crushing wall and produce extrusion with rolling mortar wall.When material enters the crushing chamber through upper hopper,it will be extruded and crushed and discharged out of the crushing wall,so as to achieve crushing effect.By adjusting the size of discharging opening.we can get appropriate material particle size.

Characteristics:

This machine uses hydrauilic clearing system,which reduced downtime and maintenance process in a safe and an efficient way.Its unique hydraulic overload protection system can automatically release foreign matters in machine body such as iron block and can reset immediately to ensure system normal operation.The new structure integrates safe cylinder and cleaning cylinder,making the machine more compact.The method of adjusting the discharge opening changes to hydraulic rotary unit gear adjustment from push cylinder drive.Therefore,the adjustment is more fast and smooth and work efficiency improved greatly.

| Model | Cavity type | Feed lnlet(mm) | max feed granularity(mm) | min discharge | min discharge | motor power(kw) | mainengine weight(kg) | ||||

| Stroke | Stroke | Stroke | Stroke | Stroke | Stroke | ||||||

| PYY100 | 16 | 22 | 16 | 22 | 75-90 | 6000 | |||||

| A | 150 | 120 | 12 | 15 | 39 | 37 | |||||

| B | 130 | 105 | 10 | 11 | 33 | 31 | |||||

| C | 100 | 85 | 7 | 9 | 33 | 30 | |||||

| D | 40 | 32 | 5 | 6 | 31 | 29 | |||||

| PYY200 | 18 | 25 | 18 | 25 | 160-200 | 10600 | |||||

| A | 220 | 180 | 18 | 22 | 35 | 30 | |||||

| B | 150 | 120 | 15 | 19 | 35 | 30 | |||||

| C | 80 | 60 | 9 | 12 | 35 | 30 | |||||

| D | 40 | 32 | 6 | 8 | 35 | 30 | |||||

| PYY300 | 25 | 32 | 220-280 | 15500 | |||||||

| A | 230 | 190 | 20 | 25 | 45 | 40 | |||||

| B | 150 | 125 | 17 | 20 | 45 | 40 | |||||

| C | 80 | 60 | 10 | 13 | 40 | 35 | |||||

| D | 40 | 32 | 6 | 8 | 40 | 35 | |||||

| PYY500 | 25 | 32 | 40 | 25 | 32 | 40 | 250-355 | 22500 | |||

| A | 230 | 180 | 22 | 26 | 30 | 50 | 45 | 40 | |||

| B | 150 | 125 | 19 | 22 | 26 | 48 | 43 | 38 | |||

| C | 100 | 80 | 12 | 14 | 16 | 40 | 35 | 30 | |||

| D | 50 | 40 | 8 | 10 | 12 | 30 | 25 | 20 | |||

| Model | Stroke | tight-side discharge gate(mm) production capacity(t/h) | |||||||||

| 8 | 12 | 16 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

| PYY100 | 16 | 35-40 | 45-55 | 55-65 | 65-75 | 75-85 | 90-100 | 105-115 | |||

| 22 | 45-50 | 55-65 | 65-75 | 75-90 | 85-105 | 100-125 | 115-135 | ||||

| PYY200 | 18 | 65-75 | 75-90 | 85-105 | 100-125 | 135-150 | 160-175 | 170-190 | |||

| 25 | 90-110 | 110-130 | 125-155 | 160-180 | 185-210 | ||||||

| PYY300 | 25 | 100-120 | 110-135 | 140-165 | 150-180 | 170-200 | 200-230 | 230-260 | 250-290 | 270-310 | |

| 32 | 110-135 | 130-150 | 180-205 | 190-220 | 210-250 | 240-280 | 270-310 | 290-330 | 310-350 | ||

| PYY500 | 25 | 150-170 | 165-185 | 180-200 | 200-220 | 230-250 | 270-290 | 300-330 | 330-360 | 365-400 | 410-450 |

| 32 | 210-230 | 230-260 | 260-290 | 280-310 | 330-250 | 390-420 | 420-450 | 460-500 | |||

| 40 | 240-260 | 270-290 | 300-320 | 330-350 | 420-440 | 480-520 | 530-570 | ||||

Main Features:

1. Model for the latest products, a wide range of applications, with a compact structure, long service life, high work efficiency.2. Adjustable for easy wear parts, Easy replacement of wear and spare parts3. High capacity, Less costly and Easy to install

4. The machine has a large crushing ratio, uniform product size, simple structure, convenient maintenance, can crush the compressive strength of a variety of materials is not more than 320 MPa, is the first choice for primary crushing equipment.

5. First-class technology, reliable pre-sale customer service quality. The products meet European CE certification standards.

Packaging & Shipping

Packaging Details:

We will load different sizes of packing according to different machine sizes, and the normal packing is in wooden cases (size: L *). If exported to European countries, wood frame will be fumigation. If the container is too tight, we will use the PE film according to the customer's special requirements.

Delivery time:

We are based on the actual needs of customers, to carry out tailor-made sales. By senior engineer to design scheme, after receipt of customer deposits began production, regardless of the size of the equipment we can deliver the goods in two weeks, delivered the balance after delivery.

Our Services

Pre-Sales Service

1, Inquiry and consulting support.

2,Pre-sale service:Freely provide project designing, process designing, choosing suitable equipment for you.

3, View our Factory.Field trips to sell products.

After-Sales Service

1,After acceptance of the equipment, we will draft the construction program and detailed process, and complete the export process

2,After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

Advantages of DaTong Brand of Stone Production Line:

1. Complete stone production line,the Crusher near to turn-key project;

2. Stationary type or mobile type for choosing

3. First class workmanship.Reliable quality with CE approved, reaching to European standard

4.Updating in design and function year by year, Invention technical patent.Forms our own unique design by considering of saving more cost and improve the processing capacity for user’s consideration.

And More:

Our Customer

We in accordance with the requirements of customers, for customers provide a complete production line crusher, remove senior engineer to site installation and training machine, and provide a detailed proposal for operation training for customers, according to customer's site requirements and application, we will help customers to choose the right equipment, drilling rigs, loaders, trucks, excavators and other equipment.

Engineers exchanges with foreign clients working abroad:

Certificate

FAQ

1.Installation:

If the buyer ask the seller to sent the technicians to guard to install the machines in the site, the buyer should take all the charges for the technicians and pay the saBest Quality China High Recovery Rate small cone crusher with low price (30USD each person one day).

2.What about Warranty?

Hi, Ours Warranty is 1 year for whole machinery .

Spare parts . For wear parts, we guarantee the high quality parts for long-term supply for Crusher.

3.Payment Method:

By L/C,D/A,D/P,T/T,Western Union,MoneyGram

4.If you want us recommend a suitable type and best offer for you ,please let us know as follows:

1). You only need one cone crusher or a whole crushing line?(include the feeder,crusher,screen,conveyor and so on)

2).what is the max size of the stone (mm/inch )?

3).what is the output size you need ?

4). What is the stone type? , marble or others ?

5.What could you help me to do for the business ?

Many thanks for your trust , we can provide you with proposal chart for complete production lines Crusher , spot inspection and operator traning according to your demands and the conditions of applied spot , we can help you choose the right equipments ,drilling rig ,loader ,trucks ,excavators and so on .

Contact Us

Best Quality China High Recovery Rate small cone crusher with low price is the orginal cone crusher, which internationly advanced and longtime popular.

Single Cylinder Hydraulic Cone Crusher, hydraulic cone crusher and symons cone crusher concentrates on the high-frequency, optimization of cavity and reasonable impact, Single Cylinder Hydraulic Cone Crusher based on conception of laminated crushing principle and more crushing and less grinding, Best Quality China High Recovery Rate small cone crusher with low price heavily.Single Cylinder Hydraulic Cone Crusher is widely used to crush all kinds of ores and rocks with medium hardness and above, metalliferous and non-metalliferous ores, cement, construction and sand.Single Cylinder Hydraulic Cone Crusher The materials can be iron stone, non-ferrous metal ore, granite, limestone, quartzite, sandstone, cobble, etc.

HSGDJDHF

Single Cylinder Hydraulic Cone Crusher , sometimes called gyratory cone crushers. Single Cylinder Hydraulic Cone Crusher crush rock between two conical surfaces called the mantle (lower movable surface) and the concave liners above. These surfaces do the actual crushing and are constructed of high manganese steel. Best Quality China High Recovery Rate small cone crusher with low price can be used in a primary crushing role but are typically seen more often in a secondary or tertiary position. There are two types of cone crushers with respect to the pay product size: standard head and fine head cone crushers. Fine head cone crushers have a reduced-size opening and so can't take as large of feed material but can produce a finer output product. Best Quality China High Recovery Rate small cone crusher with low price action is achieved by the eccentric movement of the lower portion of the main shaft. The mantle is connected to this main shaft. Single Cylinder Hydraulic Cone Crusher The gyrating action of the main shaft causes the gaps between the mantle and liners to change dimension and perform the actual crushing.

JHEDEF