I.CPYQ Cone Crushers

CPYQ single-cylinder hydraulic cone crusher is widely used in secondary, tertiary and forth crushing of various stones and rocks with medium and high hardness. It is featured by advanced design, simple structure, compact appearance, high crushing capacity, easy operation and maintenance. The craft process can be automatically controlled by adjusting discharge opening through hydraulic device, and carrying out overload protection. Main shaft is supported both from the top and bottom, among which, the top adopts spherical support, which can endure bigger crushing force and stroke. Special crushing chamber that is designed according to the principle of lamination reduces direct abrasion to liners, and thus lengthens the service life of liners. The product size fraction comes to more even and cubic shape proportion increases apparently. Different crushing chambers are optional to meet different requirements. By controlling feeding equipment and giving full feed to crusher, lamination crushing can be realized to the furthest. Automatic control system can test and make up worn-out liners, adjust discharge opening automatically, ensure even product granularity and enhance the liner utilization ratio.

II. Features of CPYQ Cone Crushers

1. Diverse Crushing chambers,easy replacement, Extra-coarse type, coarse type and medium type are equipped with feed bunkers having material level detection function, fine type is equipped with the average feeding material device.

2. Displacement sensor can quickly, accurately detect, set the size of the discharge opening.

3. Accumulator and the throttle valve can cooperate with hydraulic cylinder, automatically discharge iron to protect the main engine when iron and other can’t be crushed materials enter into the crushing chamber.

4. Concave for cone crusher and mantle for cone crusher adopt none filler materials method, for its simple fastening way, quick replace speed, so as to greatly reducing the downtime.

5. Helical bevel gear has a bigger transmission torque, smoothly and low noise.

6. The dust-laden air line ensures the internal clean, make all pieces of copper friction of Janpan Technology 850 to 1450 tph Ore Hydraulic Cone Crusher life.

7. The upper main shaft joints with upper frame by oscillating bearing, spindle moves more flexible, and has Janpan Technology 850 to 1450 tph Ore Hydraulic Cone Crusher service life.

8. The lubrication device has a variety of flexible cooling ways, widely applied in range area.

III. Intelligent Functions of CPYQ Cone Crushers

1. The hydraulic and lubricating system can be adjusted automatically according to the oil pressure, oil temperature, flowrate, etc.

2. The size of the discharge opening can be automatically detected and adjusted to ensure the stability of the product size.

3. Iron or other super hard material can be expelled automatically, with alarm launched at the same time, to protect the equipment from severe damage.

4. Real time monitoring on the abrasion of the mantle and concave is executed , so that a reminder for replacement can be released in time.

5. The start-up self-checking function makes the start and stop process of the machine safer and more reliable.

6. Various sensors are applied to achieve a full range real-time monitoring of all subsystems and key parts of the equipment, which makes accurate control, safe production, fault diagnosis, etc. come true.

7. With networking function, local data collected can be uploaded to realize the remote monitoring on equipment working conditions in real time and analysis on historical big data.

IV.CPYQ Cone Crushers Structure Diagram

V.Specifications of CPYQ Cone Crushers

VI.Specifications of CPYQ Cone Crushers

|

|

|

|

|

|

|

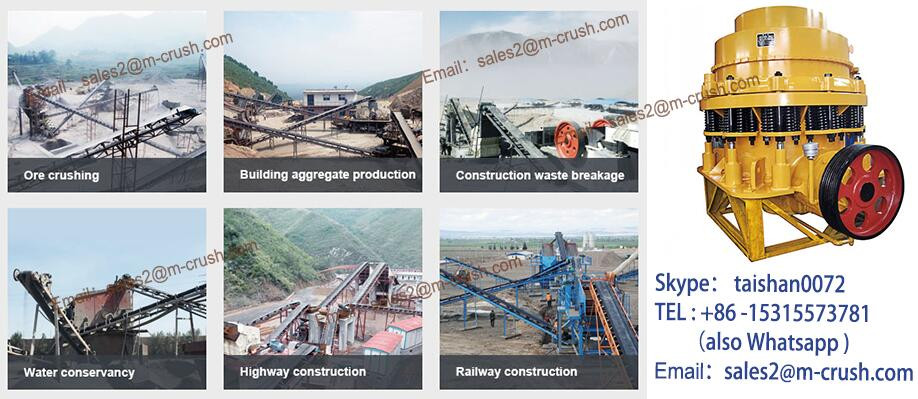

VII Company Introduction

Janpan Technology 850 to 1450 tph Ore Hydraulic Cone Crusher (TRUSTON CRUSHER) was established in 2008, and got investment fund from TECHSHEEN group in 2013.

TRUSTON CRUSHER commits to design, manufacture, market, install and debug all kinds of jaw, cone, impact, hammer, VSI, roller and screen-type crushers, and complete crushing and screening plant, complete sand making plant, and complete grinding mill system.

Presently, TRUSTON CRUSHER invested RMB420000000 to build an intelligent heavy-type mining machinery industrial park in Shanghai Free Trade Zone—Lingang Heavy Industry Area. This modern new factory will be completed in second half year of 2016, at that time, it will become the most powerful production base of intelligent crushing and screening equipment in China.

Janpan Technology 850 to 1450 tph Ore Hydraulic Cone Crusher is the orginal cone crusher, which internationly advanced and longtime popular.

Single Cylinder Hydraulic Cone Crusher, hydraulic cone crusher and symons cone crusher concentrates on the high-frequency, optimization of cavity and reasonable impact, Single Cylinder Hydraulic Cone Crusher based on conception of laminated crushing principle and more crushing and less grinding, Janpan Technology 850 to 1450 tph Ore Hydraulic Cone Crusher heavily.Single Cylinder Hydraulic Cone Crusher is widely used to crush all kinds of ores and rocks with medium hardness and above, metalliferous and non-metalliferous ores, cement, construction and sand.Single Cylinder Hydraulic Cone Crusher The materials can be iron stone, non-ferrous metal ore, granite, limestone, quartzite, sandstone, cobble, etc.

HSGDJDHF

Single Cylinder Hydraulic Cone Crusher , sometimes called gyratory cone crushers. Single Cylinder Hydraulic Cone Crusher crush rock between two conical surfaces called the mantle (lower movable surface) and the concave liners above. These surfaces do the actual crushing and are constructed of high manganese steel. Janpan Technology 850 to 1450 tph Ore Hydraulic Cone Crusher can be used in a primary crushing role but are typically seen more often in a secondary or tertiary position. There are two types of cone crushers with respect to the pay product size: standard head and fine head cone crushers. Fine head cone crushers have a reduced-size opening and so can't take as large of feed material but can produce a finer output product. Janpan Technology 850 to 1450 tph Ore Hydraulic Cone Crusher action is achieved by the eccentric movement of the lower portion of the main shaft. The mantle is connected to this main shaft. Single Cylinder Hydraulic Cone Crusher The gyrating action of the main shaft causes the gaps between the mantle and liners to change dimension and perform the actual crushing.

JHEDEF