Product Description

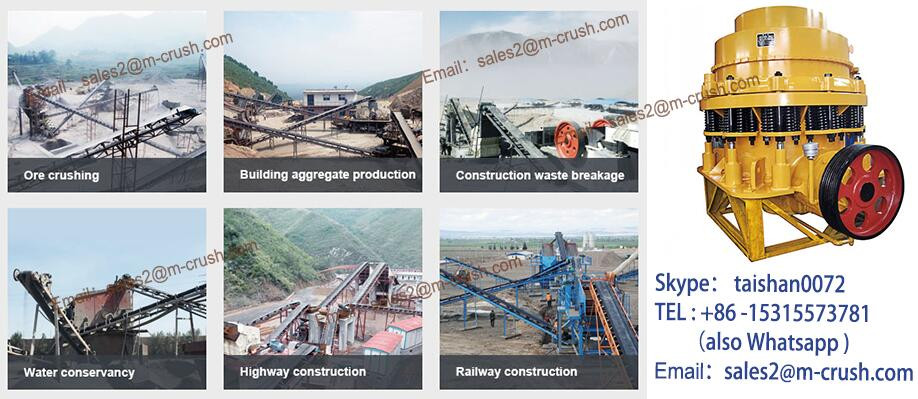

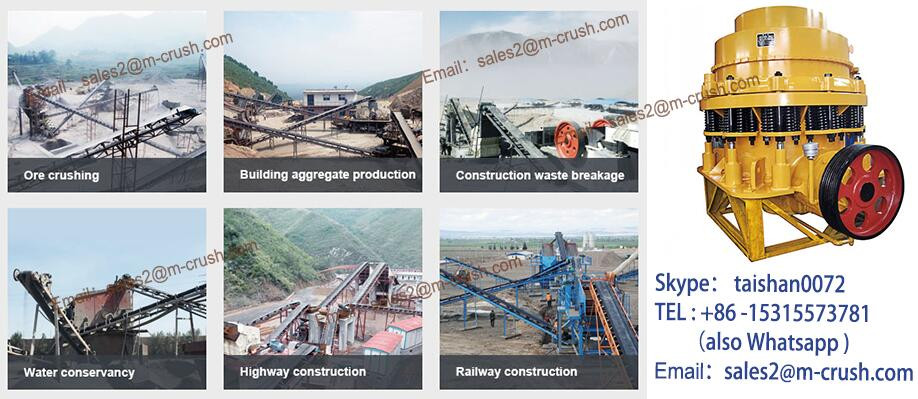

Product Application

FXMCS(H) series single-cylinder hydraulic cone crusher, widely used in the intermediate, fine and ultrafine crusher process, is researched and developed by adopting the world’s most advanced crushing technology, as well as integrating mechanics, hydraulics,electric, intelligent control and other technologies together. It has such advantages as brand new structure, optimized laminating crushing chamber, as well as the full intelligent and automatic controlling system, which makes the HXCS(H) series single-cyliner hydralic cone crusher have the unparalleled performance characteristics that traditional cone crusher cannot compare such as various selectable chamber types, high crushing efficiency, low cost of production, convenient adjustment and maintenance, cubric finished productions sizes, ect.

Main Features of Single-cylinder hydraulic cone crusher

1) Large processing capacity & high crushing efficiency;

2) Laminating crushing & excellent particle shapes of finished product;

3) Multiple chambers combined with the best strokes, adapt to the requirements of various kinds of particle sizes;

4) Long lifespan liner

5) Simple structure, convenient maintenance and low operating coat.

The Parameters of Single-cylinder hydraulic cone crusher

1.Technical parameters of HXCS Secondary crushing series single-cylinder Hydraulic Cone crusher

| Model | FXMCS420 | FXMCS430 | FXMCS440 | FXMCS660 |

| Max.feeding(mm) | 240 | 360 | 450 | 560 |

| Adjusting Range of Discharging Opening (mm) | 19-38 | 19-54 | 25-54 | 38-83 |

| Capacity(t/h) | 70-165 | 105-345 | 219-605 | 310-1050 |

| Motor Power(kw) | 90 | 160 | 250 | 315 |

| Main machine of weight(t) | 7.5 | 12.6 | 19.5 | 36.3 |

2.Technical parameters of HXCS fine crushing series single-cylinder Hydraulic Cone crusher

| Model | FXMCH420 |

FXMCH430 |

FXMCH440 |

FXMCH660 |

| Max.feeding(mm) |

150 | 200 | 215 | 300 |

| Adjusting Range of Discharging Opening (mm) |

4-32 | 6-38 | 8-45 | 13-51 |

| Capacity(t/h) |

30-135 | 63-215 | 95-369 | 175-670 |

| Motor Power(kw) |

90 | 160 | 250 | 315 |

| Main machine of weight(t) |

5.7 | 9.5 | 14.5 | 28 |

Customer Site

Customer Site

And Our machine have been exported to the world's five continents, through the foreign trade company and deeply loved by people of all countries.

Processing workshops

Shanghai High quality Cone crusher standard parts Heavy Industry Machinery Co.Ltd is located in Pudong New Area, Shanghai, China. Found in 1986, our company is a large joint-stock enterprise of producing heavy mining machinery and civil machinery. After thirty years of construction and development, High quality Cone crusher standard parts Heavy Machinery has become a famous production and export base of mining machinery and civil machinery in China.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| Packaging | |

| Size | According to the dimensions of machine |

| Weight | According to the dimensions of machine |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging | |

| Size | According to the dimensions of machine |

| Weight | According to the dimensions of machine |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

1.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.

2.Guaranteed:

If products’ quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.Service and Payment Terms?

A. We usually accept T/T, L/C;

B. T/T: 30% in advance as down payment, the balance before delivery;

C. We take pictures of finished products before delivery.

Multi-cylinder hydraulic cone crusher

91.8% Response Rate

Symons cone crusher

91.8% Response Rate

Spring cone crusher

91.8% Response Rate

Based on traditional crushing device and problem reformation of previous users, Multi-cylinder hydraulic cone crusher is researched and developed by combining modern material technology and computer technology. As it uses better crushing frequency and eccentric distance, the fine fraction content of the crushed products is higher, and the finished product ratio reaches up to 95%.

Symons Cone Crusher is widely used in Mining industry. It is suitable for hard stone such as granite and balsalt. The friction disc design and rotation of eccentric shaft bushing around fix cone plus more reasonable "labyrinthseal" system are unique features of GYS series, which have more advantages like larger application scope, more smooth functioning comparing with spring and traditional cone crusher.

Cone crusher, commonly refer to spring cone crusher, it adopts laminated crushing technology to guarantee the crushing ratio and particle shape.

Cone crusher can be used for primary cruhing, medium crushing and fine crushing of the sandstone, aggregate, gravel, granite,limestone, quartz,coal, dolomite, calcite,basalt, iron ore, gold ore, copper ore, etc in mining, quarry, construction and other industries.

High quality Cone crusher standard parts is the orginal cone crusher, which internationly advanced and longtime popular.

Single Cylinder Hydraulic Cone Crusher, hydraulic cone crusher and symons cone crusher concentrates on the high-frequency, optimization of cavity and reasonable impact, Single Cylinder Hydraulic Cone Crusher based on conception of laminated crushing principle and more crushing and less grinding, High quality Cone crusher standard parts heavily.Single Cylinder Hydraulic Cone Crusher is widely used to crush all kinds of ores and rocks with medium hardness and above, metalliferous and non-metalliferous ores, cement, construction and sand.Single Cylinder Hydraulic Cone Crusher The materials can be iron stone, non-ferrous metal ore, granite, limestone, quartzite, sandstone, cobble, etc.

HSGDJDHF

Single Cylinder Hydraulic Cone Crusher , sometimes called gyratory cone crushers. Single Cylinder Hydraulic Cone Crusher crush rock between two conical surfaces called the mantle (lower movable surface) and the concave liners above. These surfaces do the actual crushing and are constructed of high manganese steel. High quality Cone crusher standard parts can be used in a primary crushing role but are typically seen more often in a secondary or tertiary position. There are two types of cone crushers with respect to the pay product size: standard head and fine head cone crushers. Fine head cone crushers have a reduced-size opening and so can't take as large of feed material but can produce a finer output product. High quality Cone crusher standard parts action is achieved by the eccentric movement of the lower portion of the main shaft. The mantle is connected to this main shaft. Single Cylinder Hydraulic Cone Crusher The gyrating action of the main shaft causes the gaps between the mantle and liners to change dimension and perform the actual crushing.

JHEDEF