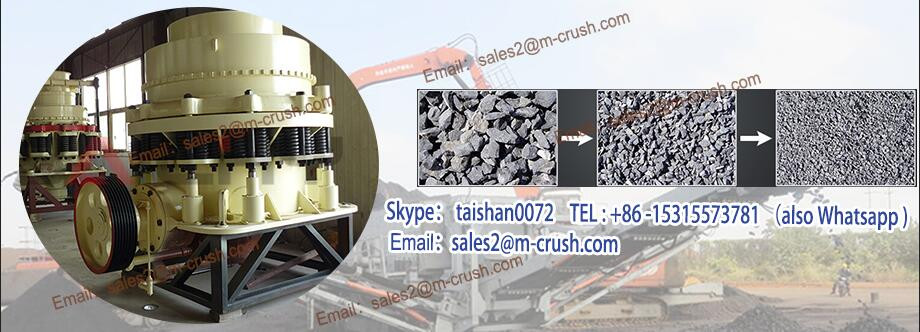

Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher

Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher-Product Description

High Quality Gold Mining Machine Cone Crusher From Crushing Plant adopts design to

speed up main shaft speed. The unique crushing chamber replace system can quickly replace components in crushing chamber to meet different size requirement. It is widely used in the fields of metallurgy, construction, hydroelectric project, transport and chemical industries for crushing all sorts of hard and above medium hard ores and rocks.

improvements

Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher-Product Improvement

The supports at both ends of main shaft, scientific design of crushing chamber, double insurance control of hydraulic and lubricating system.

Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher—Product Advantages

The cone crusher owns support at both ends of main shaft which can bear larger crushing force improving the crushing efficiency. Processing capacity is increased 35% ~ 60% than old type spring cone crusher.

Scientific design of crushing chamber and laminated crushing principle improve the cube proportion in end product and reduce the needle flake type stone. The particle size becomes more uniform.

Double safety control of hydraulic and lubricating system protects the hydraulic cone crusher from overload, and lubricates bearings better.

Working Principle

Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher—Work Principle

1.This cone crusher consist of frame, transmission, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station for adjusting discharge opening. During operation, motor drives eccentric shaft shell to rotate through a horizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time.

2.In this way, the ores and rocks will be pressed and crooked and crushed.

cone crushers are widely applied in metallurgical, construction, road building, chemical and phosphatic industry. It is suitable for hard and mid-hard rocks and ores, such as iron ores, copper ores, limestone, quartz, granite, grit stone, etc.

Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher—Work Parameters

Successful Cases As Following

Jinrui 800t/d Gold Processing Project in Philippines

The project is divided into three small sub projects, which included 800t/d All slime cyanidation dressing workshop, 1000t/d Tailings dry discharge filter press workshop, 2000kg high tempreture and pressure electrolysis workshop.

1.Excavation site of civil foundation in leaching section .And the leaching tank concrete foundation completed, this section uses two dip four absorption process.

2. The welding picture of leaching tank site ,the equipment specifications isØ8*8.5, due to large volume ,the equipment is difficult to transport, so it need to weld welding on the scene.

3.The whole leaching tank has finished, the distance is the electrolysis workshop which has completed the installation. Because the construction of the project is on the summer, so it was very hot, but to rush the deadlines, the workers worked overtime, in order to achieve the objectives and tasks of the test as soon as possible.

4.The construction site of thickener civil foundation. The workers is checking the Embedded steel plate, and next is to pouring the concrete.

5.The welding of thickener shell. This diameter of this equipment can reach 22m, so it belongs to the high altitude operation.Because the construction is during the rainy season, so in order to complete the project on time, the worker is installing the steel plate in the rain.

6.The picture is the Automatic hydraulic transmission center 22m rake thickener which researched by our selves.

7.The construction site of filter workshop. The filter workshop is constructed by steel structure which not only save the civil cost, but also reduce the construction period. Press workshop installation is completed, the operator is washing cloth.

8.The installaton completion of filter workshop, this equipment is 2000kg high tempreture and pressure electrolysis equipment.

9.The overview of our working achievement, and through 90 days harding working, our project was completed successfully.

Lingbao Jinrui Mineral Processing Equipment Co.,Ltd is founded in 1994, The company covers 20000 square meters, and total invested 35 million.

Our company is a professional mineral equipment manufacture which is mainly provided the overall services included mineral processing trial, equipment selection, engineering design, installation and debugging, equipment maintenance, accessory supply and personal training and so on. Our main products are: 100-2000ton/day full set of mineral processing equipment, Equipment for selecting gold and cyaniding, energy-saving ball mill, classifier, flotation machine conveyor, crusher, double-deck scrubbing thickener, electrolysis machine and so on.

Back to home : http://www.cnlbjrxk.en.Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher.com

♣Contact : Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher Cathy Luo

♣whatsapp :+0086 17839803866

♣Phone: +0086 17839803866

1. Spring Cone Crusher High-efficiency: Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher uses optimized structure such as, fixed axis, small spherical bearing, which make the efficiency is 5%-15% higher than the efficiency of traditional cone crusher.

2. Spring Cone Crusher Large capacity: The perfect combination of broken stroke, Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher broken speed and crushing chamber makes the capacity is 35%-65% larger than the capacity of traditional cone crusher under the same broken cone size.

3.Spring Cone Crusher High quality stone: Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher uses special laminated crushing principle resulting in the crushing effect of particles, so that the proportion of cube in the output clearly increased, the flake stone needless reduced and the grain size more uniform.

JHBJGSXS

4. Spring Cone Crusher More smoothly operation: When iron and other hard objects that cannot be broken into the machine,Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher the over iron protection equipment will released the objects and then reset immediately.

5. Spring Cone Crusher Multi-split hydraulic lubrication control system can ensure the double protection of the bush and overload protection.

JHVAJSHGVC

Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher pyd 1200 with high-efficiency and hydraulic pressure was widely used in mining, concrete factory, sand stone making, etc. Spring Cone Crusher's pressure resistance strength is under 350Mpa. And Mobile Fine Quarry Primary And Secondary Crushing Ore Hydraulic spring cone crusher pyd 1200 are widely suitable for primary crushing of many kinds of mining and rock such as many kinds of ores, concrete, fireproof material, bauxite, quartzite, corundum, perlite, ironstone, basalt, etc