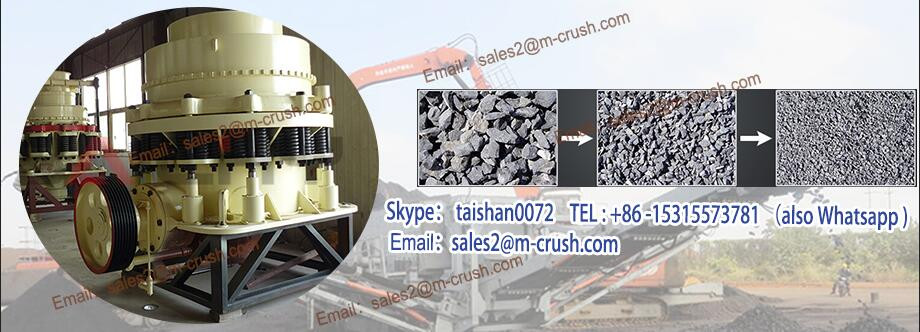

Product Description high efficient SK1400 spring cone crusher

This is a new crushing machine developed by SDSY. It is high efficient, energy saving, environmental-friendly, and economic. The company has more than ten national patents technology which are widely used in metallurgical industry, building materials, road construction and chemical industry. It is suitable for crushing ores and rocks with various hardness and material quality. The products are divided into coarse crushing, medium coarse crushing, fine crushing according to the requirements of crushing operation.

Feature of SK1400 cone crusher

The parameter weight in the table not contain the weight of electric engine, electric controlling equipment, lubricating equipment and hydraulic pressure equipment.

PS two: the crusher parameter capacity in the table meets the design output amount as the following conditions:

a)The material water content does not surpass 4%, not containing clay;

b)The fine particle smaller than the throat feeding material is below 10% in the total feeding material, and is circular distribution in the crushing cavity.

c)The feeding material bulk density 1.6t/m3, compressive strength 150Mpa.

granite, basalt, diabase, quartzite, cobble, limestone, iron ore, pebble etc.

1.The machine body is robust, good appearance and durable.

2. Semi-automatically control, hydraulically adjusted, it can effectively control the size of sand and stone, can be adjusted quickly and convenient.

3. The crusher plate has no packing required, and it is easy to change. The rolling mortar wall and broken wall, Mounting surfaces are precisely made in the special machine tools with special design.

4. The crushing cavity is specially designed. It can greatly increase the production capacity.

5. It provides iron protection, and is safe and reliable, cavity automatic clearing, fast running and time-saving.

6. The machine is a structure of labyrinth, has good grease sealing and dust prevention effect.

7. The oil circulation cooling system is designed according to a lot of domestic customers’ actual situation and characteristics. The temperature control system and pressure control system are easy to control and operate.

8.Driven by cone gear, robust and steady.

9. The copper set is made with special formula and processing technology, and it is durable.

10. It is designed to be light and compact with reasonable structure.

used in metallurgical industry, construction, road building, chemical industry and phosphate industry etc. Used for crushing various rock and ore which hardness is medium or above.

The technological process for 150t/h iron ore sand making is relatively complex and the hardness of iron ore is relatively high. In order to guarantee the volume of production and reasonably reduce operating cost, we design one set of optimized technological especially for iron ore according to traditional sand making process.

The iron ore is fed into PE-750x1060 jaw crusher uniformly by ZSW490x110II vibrating screen. The material is delivered into intermediate storage bin by belt conveyor after being crushed. The pre-screened material by feeder is conveyed to intermediate storage bin by such belt conveyor.

The material in the storage bin is conveyed to 3YK-2460 vibrating screen by GZG1003 electromagnetic vibrating feeder. The vibrating screen divides the material into four types according to the size of the material: -5, 5-30, 30-60 and larger than 60mm. The material with diameter 0-5mm is finished product.

5-30mm material is delivered to storage bin of the crusher by belt conveyor. The material is fed to two VSI crushers by two GZG1003 electromagnetic vibrating feeders. After being treated, the material is conveyed to YK-2460 vibrating screen by belt conveyor. The material smaller than 5mm is finished product and the material larger than 5mm will be delivered back to intermediate storage bin and be treated again.

30-60mm material is delivered to storage bin of cone crusher. The material is fed uniformly to PYFD1310 compound cone crusher by GZG1003 electromagnetic vibrating feeder. After being crushed, the material is conveyed back to 3YK-2460 vibrating screen by belt conveyor.

Material larger than 60mm is delivered to PEX-300x1300 fine type jaw crusher and gets crushed. After being crushed, the material is conveyed back to 3YK-2460 vibrating screen by belt conveyor and gets screened.

The sand making solution for 150t/h iron ore fully takes the characteristics of the raw material into consideration, applies reasonable design, effectively reduces the operating cost and guarantees stable volume of production of the production line.

III. Layout of Equipment

| SPECIFICATIONS FOR PYB1200 cone crusher | |||

| MOTOR |

MODEL | kw | 220 |

| type | high efficient | ||

| Main performance parameters |

size | 1400 | |

| crushing diameter | mm | 1400 | |

| cavity | medium | ||

| Hydraulic pressure station |

Hydraulic system | high efficient | |

| Main pump | 5.5 kw | ||

| cubic | 2 m3 | ||

SK1400 symons cone crusher Main Features

1.High Performance.

Through optimized design of the chamber and the combination of reasonable speed and stroke, CS series cone crusher can produce more with the same movable cone diameter. Therefore, compared with the same type cone crusher, it has better performance and higher production capacity.

2.High Stability.

If iron or some other things can not be crushed get into the chamber, the protection device will discharge it automatically, then resets. This protection device has fixed return point of discharge opening, which guarantees discharge opening get back to the correct position after iron gets through the chamber.

3.Optimized bracket design

Adopting new cantilever crane enables more equal force, effectively preventing the abrasion on the frame caused by impacting force of material. Non-destructive testing system improves the overall strength of frame and the operation reliability and prolongs the service life.

4.High Reliability

Adoption of large diameter main cone, heavy mainframe and independent thin oil lubrication system makes the crusher durable and reliable..

5.Easy to Fix and Operate

All of the parts are easy to assemble and disassemble from top or lateral side, so fixed cone and movable cone can be disassembled easily. Bronze sliding bearing has good load capacity in breaking and vibrating situation, besides, it is cheaper and easier to fix than rolling bearing.

6. Low Producing Cost.

For high producing capacity, high reliability and convenience to fix, the operation costs were decreased greatly.

7 .Wide Application

The character of CS series cone crusher makes crushers playing their maximum performance for applying to all kinds of crushing process: from primary crushing to finely crushing, from fixed crushing to the mobile crushing station. The CS series cone crusher has wide ranges of crushing chambers, so customers can choose the different chambers based on their different request.

8. Individual lubrication.

Thin oil lubrication can protect the bearing very well and achieve the automatic protection.

Detailed Images

Detailed Images

PYB1200 cone crusher Parts

Name: main shaft

Brand: SDSY

Original: china

Adoption of large diameter main cone, heavy mainframe and independent thin oil lubrication system makes the crusher durable and reliable.

PYB1200 cone crusher main body

Name:main body

Brand: SDSY

Original: china

1. Frame 2.Big belt wheel 3.Counter shaft 4.Pinion 5.Gear 6.Main shaft 7.Spring device 8.Main Unit 9.Mantle 10. Bowl Liner 11.Adjustment bush 12.Material distributing plate 13.Feed hopper 14.Adjusting ring

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

| Packaging | |

| Size | 3911X2870X3771 MM |

| Weight | 55T |

| Packaging Details |

BY BULK |

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

impact crusher

91.8% Response Rate

mobile jaw crusher

91.8% Response Rate

jaw crusher

91.8% Response Rate

1. Spring Cone Crusher High-efficiency: high efficient SK1400 spring cone crusher uses optimized structure such as, fixed axis, small spherical bearing, which make the efficiency is 5%-15% higher than the efficiency of traditional cone crusher.

2. Spring Cone Crusher Large capacity: The perfect combination of broken stroke, high efficient SK1400 spring cone crusher broken speed and crushing chamber makes the capacity is 35%-65% larger than the capacity of traditional cone crusher under the same broken cone size.

3.Spring Cone Crusher High quality stone: high efficient SK1400 spring cone crusher uses special laminated crushing principle resulting in the crushing effect of particles, so that the proportion of cube in the output clearly increased, the flake stone needless reduced and the grain size more uniform.

JHBJGSXS

4. Spring Cone Crusher More smoothly operation: When iron and other hard objects that cannot be broken into the machine,high efficient SK1400 spring cone crusher the over iron protection equipment will released the objects and then reset immediately.

5. Spring Cone Crusher Multi-split hydraulic lubrication control system can ensure the double protection of the bush and overload protection.

JHVAJSHGVC

high efficient SK1400 spring cone crusher pyd 1200 with high-efficiency and hydraulic pressure was widely used in mining, concrete factory, sand stone making, etc. Spring Cone Crusher's pressure resistance strength is under 350Mpa. And high efficient SK1400 spring cone crusher pyd 1200 are widely suitable for primary crushing of many kinds of mining and rock such as many kinds of ores, concrete, fireproof material, bauxite, quartzite, corundum, perlite, ironstone, basalt, etc