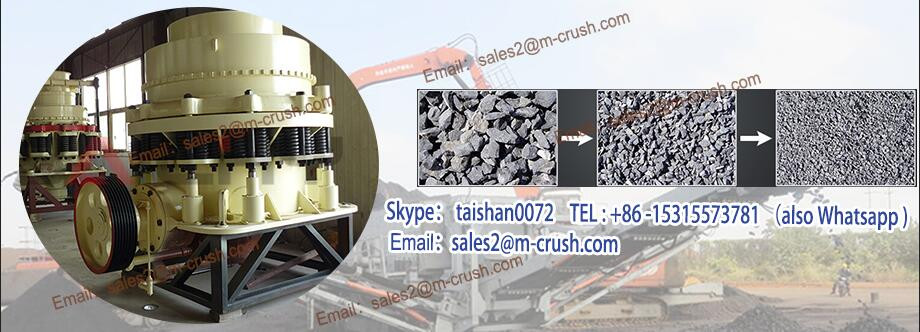

New Type High-performance Spring Cone Crushers for chrome ore

- Description:

1. Cone crusher is my company introduction of American technology, combined with the international forefront of alloy materials and mechanical manufacturing technology independent research and development of a highly efficient crusher.

2. Especially suitable for middle and high hardness such as chrome ore, basalt, granite brittle material, is widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramic industries such as finely and finely homework .

- Advantages and Features:

1. Spindle are supported on both ends of the up and down, can bear greater crushing force and stroke ;

2. Stroke, swing frequency and the perfect combination of crushing cavity form, make the machine more than 40% higher than that of yield of spring cone crusher ;

3. High frequency, large stroke, and high energy input, the material in the lining of the crushing cavity pressure broken, obviously improve the cube content in the product .

4. Hydraulic adjust the discharging mouth size, facilitate remote control product granularity, the province, save trouble ;

5. Wearing parts, and convenient to replace completely get rid of the spring cone crusher replacing parts packing problem;

6. The use of circular arc spiral bevel gear, make the equipment operation more stable, less noise, transmission efficiency is higher ;

7. Hydraulic protection, overload after crushing cavity automatic reset .

- Working Principle:

1. In the process of cone crusher work, motor through the driving device drives the eccentric set of rotating, moving cone under the forced motion of eccentric shaft sleeve do rotary oscillation, dynamic cone near static cone section becomes a crushing cavity, the material under dynamic and static cone cone of extrusion and the impact and breakage for many times.

2. Dynamic cone leave that section, it has been broken to the required size of material fall under their own gravity, from the bottom of the cone. To be broken material from the inlet into the cone crusher .

- Some factors infused aggregate crushing plantsce Spring Cone Crusher :

1. Choose right crushing cavity according to the materials to be crushed;

2. The feeding size should be right;

3. Materials are distributed equally around the crushing cavity;

4. Automatically control system is applied;

5. Discharge opening of cone crusher works normally;

6. The model of belt conveyor depends on the max. processing ability of the crusher;

7. Choose the right screen model for advance screening and closed screening.

- Each size for Sring Cone Crusher

- Spring Cone Crusher Workshop production line

Cone Crusher in Customer Factory

1. Spring Cone Crusher High-efficiency: used aggregate crushing plants uses optimized structure such as, fixed axis, small spherical bearing, which make the efficiency is 5%-15% higher than the efficiency of traditional cone crusher.

2. Spring Cone Crusher Large capacity: The perfect combination of broken stroke, used aggregate crushing plants broken speed and crushing chamber makes the capacity is 35%-65% larger than the capacity of traditional cone crusher under the same broken cone size.

3.Spring Cone Crusher High quality stone: used aggregate crushing plants uses special laminated crushing principle resulting in the crushing effect of particles, so that the proportion of cube in the output clearly increased, the flake stone needless reduced and the grain size more uniform.

JHBJGSXS

4. Spring Cone Crusher More smoothly operation: When iron and other hard objects that cannot be broken into the machine,used aggregate crushing plants the over iron protection equipment will released the objects and then reset immediately.

5. Spring Cone Crusher Multi-split hydraulic lubrication control system can ensure the double protection of the bush and overload protection.

JHVAJSHGVC

used aggregate crushing plants pyd 1200 with high-efficiency and hydraulic pressure was widely used in mining, concrete factory, sand stone making, etc. Spring Cone Crusher's pressure resistance strength is under 350Mpa. And used aggregate crushing plants pyd 1200 are widely suitable for primary crushing of many kinds of mining and rock such as many kinds of ores, concrete, fireproof material, bauxite, quartzite, corundum, perlite, ironstone, basalt, etc