China high efficiency and continuous working fine sand vibrating screen

Introduction

This series machines use excellent vibrant motor as power source, so that the materials can be thrown up on the sieve and forward to make a straight movement. It can be equipped with single or multi-screen to achieve the goal of grading, impurity- removing, testing, washing , dehydration etc.

Working principle

Linear vibrating screen mainly consists of the eccentric block vibrator, screen box, motor, and supportive device.Through the flexible coupling, the motor drives the eccentric block of the vibrator at high rotary speed, generating the centrifugal force, and then lead the screen box to do circular movement by the amplitude. After that, the materials in the slope screen surface will be cast continuously by the force generated from the screen box, then realize the purpose of classifying.

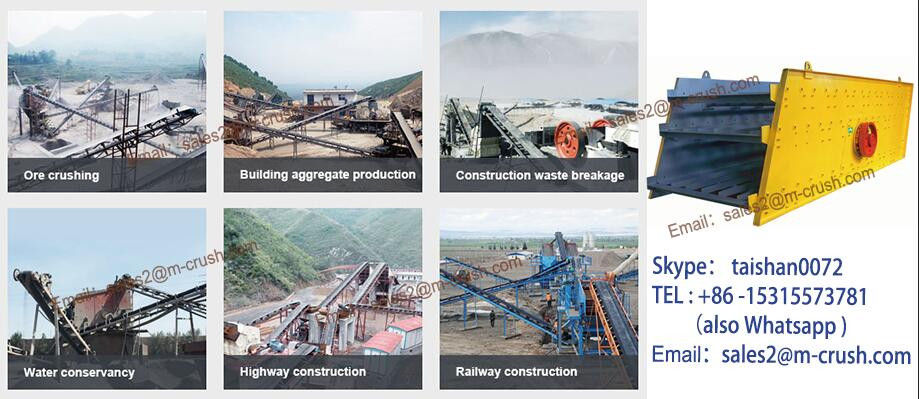

Applied fields

It is widely used in grinding materials, chemical, construction, chemicals, pharmacy, metallurgy, ceramics, fertilizers, coal industry to screening and grading the granular and powder bulk materials.

Feature

1. High sieving efficiency, high utilization ratio of screen,

2. Continuous working.

3. environmental-friendly:sealed structure avoids dust overflow,

4. no jam

5. easy to replace net , easy maintenance

Structure diagram

Technical parameter

Model |

Screen size (mm) |

Layer |

Sieving mesh (mesh) |

Capacity

|

Vibration time (rpm)

|

Double Amplitude (mm) |

Power (kw) |

Inclination (°) |

Shape dimension (mm) |

DZSF520 |

500×2000 |

1 |

2-200 |

0.05-5 |

960 |

6-7 |

2×0.4 |

45-60 |

2140×808×848 |

2DZSF520 |

2 |

0.05-5 |

960 |

6-7 |

2×0.4 |

45-60 |

2199×808×878 |

||

3DZSF520 |

3 |

0.03-5 |

1450 |

4-6 |

2×0.4 |

45 |

2256×808×938 |

||

DZSF525 |

500×2500 |

1 |

0.06-8 |

960 |

5-7 |

2×0.4 |

45-60 |

2642×808×848 |

|

2DZSF525 |

2 |

0.06-8 |

1450 |

4-6 |

2×0.4 |

45 |

2699×808×878 |

||

3DZSF525 |

3 |

0.06-8 |

960 |

6-8 |

2×0.75 |

45-60 |

2750×808×938 |

||

4DZSF525 |

4 |

0.1-15 |

1450 |

5-7 |

2×0.4 |

45 |

2813×808×1000 |

||

5DZSF525 |

5 |

0.08-15 |

1450 |

5-7 |

2×0.4 |

45 |

2883×808×1060 |

||

6DZSF525 |

6 |

0.07-15 |

960 |

6-8 |

2×0.75 |

45-60 |

2953×808×1120 |

||

DZSF1020 |

1000×2000 |

1 |

0.12-20 |

960 |

6-8 |

2×0.75 |

45-60 |

2152×1320×900 |

|

2DZSF1020 |

2 |

0.11-20 |

960 |

5-7 |

2×0.75 |

45-60 |

2219×1320×960 |

||

3DZSF1020 |

3 |

0.10-2 |

960 |

5-7 |

2×0.75 |

45-60 |

2286×1320×1030 |

||

4DZSF1020 |

4 |

0.07-15 |

960 |

4-8 |

2×0.75 |

45-60 |

2353×1320×1100 |

||

5DZSF1020 |

5 |

0.07-15 |

960 |

4-8 |

2×1.5 |

45-60 |

2420×1320×1160 |

||

6DZSF1020 |

6 |

0.07-15 |

960 |

4-8 |

2×1.5 |

45-60 |

2487×1320×1220 |

||

DZSF1025 |

1000×2500 |

1 |

0.1-15 |

1450 |

5-7 |

2×0.4 |

45 |

2203×1320×900 |

|

2DZSF1025 |

2 |

0.08-15 |

1450 |

5-7 |

2×0.4 |

45 |

2269×1320×960 |

||

3DZSF1025 |

3 |

0.07-15 |

960 |

6-8 |

2×0.75 |

45-60 |

2336×1320×1030 |

||

DZSF1030 |

1000×3000 |

1 |

0.1-20 |

960 |

6-8 |

2×0.75 |

45-60 |

3152×1340×1120 |

|

2DZSF1030 |

2 |

0.1-20 |

960 |

6-8 |

2×1.5 |

45-60 |

3219×1340×1120 |

||

3DZSF1030 |

3 |

0.1-20 |

960 |

6-8 |

2×1.5 |

45-60 |

3286×1340×1120 |

How to get a suitable machine?? Pls kindly provide the follow information:

1. What’s the materials to process?

2. What’s the feature of the materials? Like density, moisture degree,input particle size and output particle size.

3. How many layers do you need ? And what’s the screen mesh for each layer?

4. What’s your capacity per hour?

5. What's material for the machine?Stainless steel or contact part stainless steel or carbon steel??

6. Other special requirement.

If you want to know more about our product,contact with me now.I'm always online service for you!

Mining Vibrating Screen is one of the unique product or equipment,China high efficiency and continuous working fine sand vibrating screen is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

China high efficiency and continuous working fine sand vibrating screen is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,China high efficiency and continuous working fine sand vibrating screen is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

China high efficiency and continuous working fine sand vibrating screen is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD