1.

Product FeatureMining screening equipment, vibrating screen equipment for sintering mine—Product feature

1.Simple design, reliable structure, easy maintenance and high productivity.

2.With the changing feeding volume, the vibration amplitude also changes accordingly. When the feeding volume lessened, the amplitude increases; when the feeding volume increases, the amplitude decreases.

Mining screening equipment, vibrating screen equipment for sintering mine—Product application

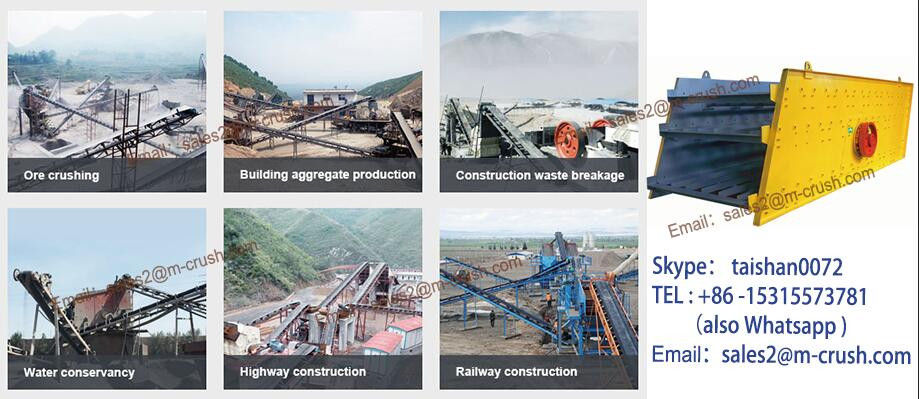

In the production process, the linear screen machine can send the block and granule materials from the storage bin to the receiving device uniformly, regularly and continuously. In the sand and gravel production line, the screening machine can be fed continuously and evenly, and the materials are screened in a rough way, which is widely used in metallurgy, coal, ore dressing, building materials, chemicals, abrasives and other industries crushing, screening joint equipment.

Working Principle

Mining screening equipment, vibrating screen equipment for sintering mine—Product Principle

1.Stable vibration and reliable operation.

2.Uniform feeding; stable working performance.

3. Compact structure; high intensity; impact and abrasion resistant.

Technical Parameters

Mining screening equipment, vibrating screen equipment for sintering mine—technical parameters

Our customers

Our customers

Feilvbin customers visit our factory

Jinrui mining is committed to providing customers with professional, perfect and efficient products and services.Jinrui has projects in foreign countries, included Feilvbin,Laos,Africa,etc.Including EPC Project and many equipment.

Successful Cases As Following

Jinrui 800t/d Gold Processing Project in Philippines

The project is divided into three small sub projects, which included 800t/d All slime cyanidation dressing workshop, 1000t/d Tailings dry discharge filter press workshop, 2000kg high tempreture and pressure electrolysis workshop.

1.Excavation site of civil foundation in leaching section .And the leaching tank concrete foundation completed, this section uses two dip four absorption process.

2. The welding picture of leaching tank site ,the equipment specifications isØ8*8.5, due to large volume ,the equipment is difficult to transport, so it need to weld welding on the scene.

3.The whole leaching tank has finished, the distance is the electrolysis workshop which has completed the installation. Because the construction of the project is on the summer, so it was very hot, but to rush the deadlines, the workers worked overtime, in order to achieve the objectives and tasks of the test as soon as possible.

4.The construction site of thickener civil foundation. The workers is checking the Embedded steel plate, and next is to pouring the concrete.

5.The welding of thickener shell. This diameter of this equipment can reach 22m, so it belongs to the high altitude operation.Because the construction is during the rainy season, so in order to complete the project on time, the worker is installing the steel plate in the rain.

6.The picture is the Automatic hydraulic transmission center 22m rake thickener which researched by our selves.

7.The construction site of filter workshop. The filter workshop is constructed by steel structure which not only save the civil cost, but also reduce the construction period. Press workshop installation is completed, the operator is washing cloth.

8.The installaton completion of filter workshop, this equipment is 2000kg high tempreture and pressure electrolysis equipment.

9.The overview of our working achievement, and through 90 days harding working, our project was completed successfully.

Lingbao Jinrui Mineral Processing Equipment Co.,Ltd is founded in 1994, The company covers 20000 square meters, and total invested 35 million.

Our company is a professional mineral equipment manufacture which is mainly provided the overall services included mineral processing trial, equipment selection, engineering design, installation and debugging, equipment maintenance, accessory supply and personal training and so on. Our main products are: 100-2000ton/day full set of mineral processing equipment, Equipment for selecting gold and cyaniding, energy-saving ball mill, classifier, flotation machine, conveyor, crusher, double-deck scrubbing thickener, electrolysis machine and so on.

Back to home : http://www.cnlbjrxk.en.Mining screening equipment, vibrating screen equipment for sintering mine.com

♣Contact : Mining screening equipment, vibrating screen equipment for sintering mine Cathy Luo

♣whatsapp :+0086 17839803866

♣Phone: +0086 17839803866

Mining Vibrating Screen is one of the unique product or equipment,Mining screening equipment, vibrating screen equipment for sintering mine is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Mining screening equipment, vibrating screen equipment for sintering mine is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,Mining screening equipment, vibrating screen equipment for sintering mine is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Mining screening equipment, vibrating screen equipment for sintering mine is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD