High Frequency 4yk1854 vibrating screen certified by CE ISO9001:2008 GOST

Vibrating ScreenBrief introduction to Dongmeng screening equipment

Vibrating screen are used to separate materials into various sizes for further processing or for end use. The material is

separated by passing through a vibrating “screen or meshes” which has a number of different sized according to customer’s

requirements. the material falls onto attached conveyors which stock pile the end products. The end products can then

be used in the building and construction industries. It has a feature of advanced structure, powerful vibrating forces,

low vibration noise, easy maintenance, high durability and etc.

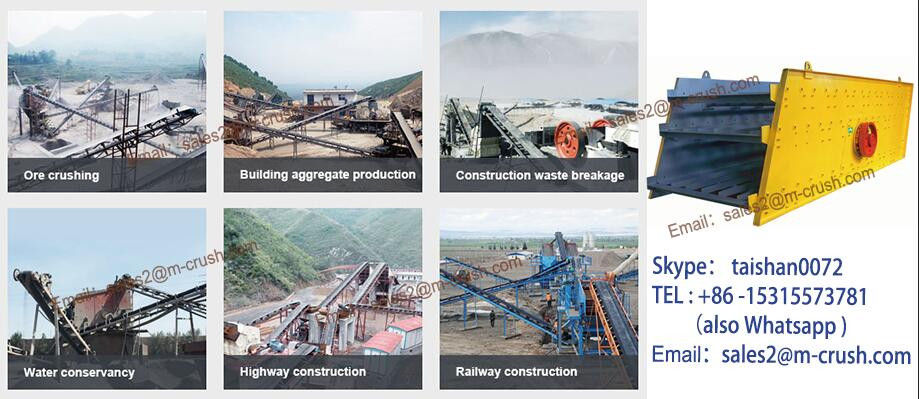

Application of screening equipment

The vibrating screen with circular motion is specially designed for quarry to separate crushed stone material into different sizes,

and is also used as a grading machine in coal dressing, ore dressing, construction material, electric and chemical industries.

Special advantages of DongMeng screening equipment from others

A). Reliable quality certified by CE and reaches European standard.

B). Two types of vibrating screen,

C). Unique and advanced design.

D). Powerful vibrating forces, low vibrating noise

E) Easy to maintain, high durability screening equipment

Working principle of YK series screening equipment

There are two eccentric shafts rotating at high speed at the same time from opposite directions, thus the strong centrifugal forc

e is formed. The component forces of centrifugal force along the vibrating direction will always overlap each other, then

counteract with that of vertical force from vibrating direction, then exciting force along single direction is formed to drive the

feeder vibrate along straight line. When materials are fed into the feeder, they may be thrown up and move like para curve,

then fall down. The materials will move forward on the slope surface of the feeder for 4yk1854 vibrating screen

Technical specifications of screening equipment

Model |

Screen |

Screen size |

Max. feed size |

Capacity |

Vibrating |

Electric motor power(KW) |

Weight |

Overall |

3YK-1245 |

3 |

1200×4500 |

200 |

15-80 |

16.2 |

11 |

4.807 |

5600×1800×1850 |

2YK-1548 |

2 |

1500×4800 |

200 |

30-180 |

13-16 |

15 |

5.800 |

5906×2100×1600 |

3YK-1548 |

3 |

1500×4800 |

200 |

30-200 |

13-16 |

15 |

6.866 |

5906×2100×1900 |

4YK-1548 |

4 |

1500×4800 |

200 |

30-250 |

13-16 |

18.5 |

7.360 |

5906×2100×2150 |

2YK-1854 |

2 |

1800×5400 |

250 |

50-300 |

16.2 |

18.5 |

6.769 |

6509×2536×1810 |

3YK-1854 |

3 |

1800×5400 |

250 |

50-300 |

16.2 |

22 |

8.285 |

6509×2536×1910 |

4YK-1854 |

4 |

1800×5400 |

250 |

50-300 |

16.2 |

30 |

9.796 |

6509×2536×2250 |

2YK-2160 |

2 |

2100×6000 |

250 |

100-400 |

16.2 |

30 |

9.680 |

7150×2670×2120 |

3YK-2160 |

3 |

2100×6000 |

250 |

100-400 |

16.2 |

30 |

10.206 |

7150×2670×2270 |

4YK-2160 |

4 |

2100×6000 |

250 |

100-400 |

16.2 |

30 |

11.800 |

7150×2670×2650 |

2YK2460 |

2 |

2400×6000 |

300 |

150-600 |

16.2 |

30 |

10.200 |

7150×2900×1950 |

3YK-2460 |

3 |

2400×6000 |

300 |

150-600 |

16.2 |

30 |

12.350 |

7150×2900×2350 |

DF-1230 |

1 |

1200×3000 |

200 |

20-200 |

16.2 |

5.5 |

15.400 |

3500×1800×1100 |

DF-1548 |

1 |

1500×4800 |

250 |

50-450 |

16.2 |

15 |

3.750 |

5330×2000×1300 |

screening equipment vibrating screen photos in our factory

Vibrating Screen photos in our factory for screening equipment vibrating screen

screening equipment vibrating screen working with water for stone vibrating screen

Delivery for Stationary crushing plant

Export standard container 20GP OR 40GP,40HQthe spare parts in wooden case.

Shanghai DongMeng Road&Bridge Machinery Co., Ltd. Is a stone crusher screening equipment vibrating screen professional manufacturer of crushing &screening

machinery in China. Shanghai Dongmeng set machinery design, development, production, sales, after-sales service as one.

We have more than 200 workers, 30 senior technical staff, with factory area of more than 20,000 square meters.

FAQ

Q:Instalation

A:At the client’s request, DongMeng can provide installation Technicians to supervise and assist in the assembly and

commissioning of the equipment. Travel and accommodation costs, plus US$50 per day per man to be met by the client.

Q:Payment

A:30% by TT as deposit on signing the contract, 70% by as final payment of balance after the client’s satisfactory inspection ofthe equipment prior to the goods leaving the DongMeng factoryQ: What about Warranty? what will we do if the machine is broken down

A: The warranty period for all of DongMeng’s structural and mechanical equipment is one year. The warranty period for allelectric motors is half one year. Wear parts are not covered by warranty unless the component part is found to be flawed. Q: What should we need to do for if we want to get a best quotation

A: Hi, if you want us recommend a suitable type for you ,please let us know as follows:

1).the capacity (tons per hour ) 2).output size 3).stone type

Q: What could you help me to do for the business ?

A: Many thanks for your trust , we can provide you with proposal chart for complete production lines ,spot inspection and operator traning according to your demands and the conditions of applied spot , we can help you

choose the right equipments ,drilling rig ,loader ,trucks ,excavators and so on Q:What's your After sales Service

A:All equipment manufactured by DongMeng is of the highest standard and very rarely have our clients experienced anymechanical problems. Should any problems occur, our team of Engineers and Technicians will respond within12 hours ofnotice by the client for water intake screen Q:Delivery time

A:Standard delivery time for stationary crusher plant is 30 days from receipt of deposit.the mobile crusher plant is 45 days,

Mining Vibrating Screen is one of the unique product or equipment,stone crusher screening equipment vibrating screen is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

stone crusher screening equipment vibrating screen is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,stone crusher screening equipment vibrating screen is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

stone crusher screening equipment vibrating screen is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD