China Linyi Wante High Efficient double deck manafacture mobile vibrating screen spring

ADVANTAGES OF VIBRATING SCREEN | |

|

1.The first choice sieving equipment after crushing 2.Multiple layers of screen,classrify different grades one time 3.Long vibrating screen line,with reliable structure 4.Strong exciting force,high screening efficiency 5.Low maintenance cost,durable screen | |

|

|

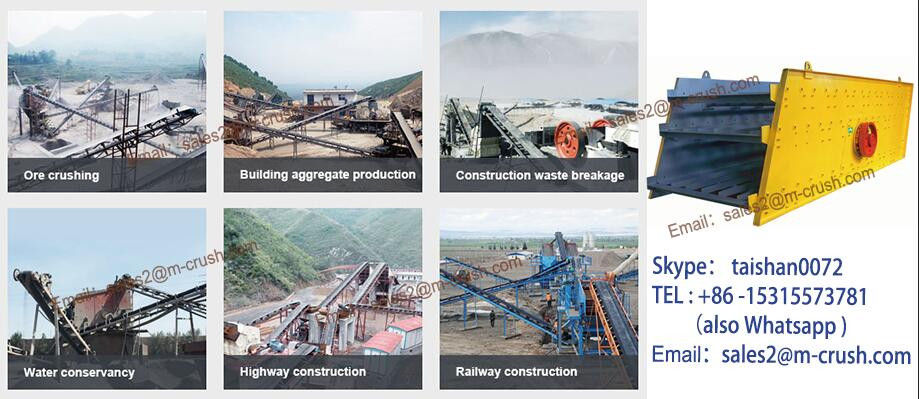

APPLICATION OF VIBRATING SCREEN | |

Application Fields |

Processing Objects |

|

SIEVING AND CLASSIFYING: Mining ,Quarry Metallurgy Building Material processing Road and Bridge Construction |

CRUSHED ORES AND SANDS: Iron Ore,Gold mineral Coal Gange,Quarze Stone Basalt,Granite, Marble Stone

|

| |

WORKING PRINCIPLE OF VIBRATING SCREEN | |

|

The motor takes the eccentic axle to rotate, changesthe eccentric axle's rotating movement into the screen's recurred Linear movement, at the same time, makes use of the materal's gravity and the screen's installed luff, to made the materials from coarse to fine, dismounted from the screen hole by turn, so realize the aim of sizing materials.

| |

|

|

| TECHNICAL PARAMETERS OF VIBRATING SCREEN | |||||||

| Model | Layers |

Screen Hole Size (mm) |

Max feeding (mm) |

Dip of Groove Surface |

Capacity (t/h) |

Vibration Frequency (r/min) |

Motor power (KW) |

| YK-1548 | 1 | 1500x4800 | 120 | 20 | 50-200 | 960 | 11 |

| 2YK-1548 | 2 | 1500x4800 | 120 | 20 | 50-200 | 960 | 11 |

| 3YK-1548 | 3 | 1500x4800 | 120 | 20 | 50-200 | 960 | 15 |

| 4YK-1548 | 4 | 1500x4800 | 120 | 20 | 50-200 | 960 | 18.5 |

| 2YK-1860 | 2 | 1800x6000 | 200 | 20 | 80-280 | 730 | 18.5 |

| 3YK-1860 | 3 | 1800x6000 | 200 | 20 | 80-280 | 730 | 22 |

| 4YK-1860 | 4 | 1800x6000 | 200 | 20 | 80-280 | 730 | 22 |

| 2YK-2160 | 2 | 2100x6000 | 200 | 20 | 100-450 | 730 | 22 |

| 3YK-2160 | 3 | 2100x6000 | 200 | 20 | 100-450 | 730 | 30 |

| 4YK-2160 | 4 | 2100x6000 | 200 | 20 | 100-450 | 730 | 30 |

OUR COOPERATION |

|

After the purchase contract signing ,we will arrange production at once,and inform you everything about the entire manufacturing process. Cooperation one day ,good friends forever. |

PACKAGING & SHIPPING |

|

1.Sand blasting coat with high quality paint; 2.Product wrapped by PP-Bubble; 3.Load container,spear Parts in wooden case 4.Transportation by sea; |

|

INSTALLATION | |

|

| |

|

After the machine arrived at your place, We will send our technicians to the producing spot for installation, commissioning and training your operating personnel. |

COMPANY INTRODUCTION |

|

|

Linyi Wante Machinery Co., Ltd was established in 1996, located in Linyi City North District National Grade Economic Development Zone. It is a high-tech enterprise collection of crusher machines, wearing-resisting materials R&D, manufacture, sales and service. For ten years, taking our enterprise spirits of “Good faith, being pragmatic, innovation, development”, through our unremitting efforts, rapidly become an important crusher and wear resistant material manufacture and export base. |

Quality Control |

|

|

Our Team |

|

Customers' Visit and Exhibition |

|

So far ,there are so many customers from all over the world to visit our company. They are mainly from Middle East ,such as : Egypt,Syria,Yemen,Oman,Jordan; Southeast Asia,for example: Philippines, Vietnam,Singapore,Myanmar, and other countries,for instance:Canada,Russian,Mongolia,Afghanistan,etc. |

Crushing Production line |

|

Related Products |

|

|

FAQ

FAQ |

Q:Installation and Commissioning |

|

A: At the client’s request, we can provide installation Technicians to supervise and assist in the assembly and commissioning of the equipment. |

Q: What will we do if the machine is broken down? |

|

A:The warranty period for all of structural and mechanical equipment is one year. Wear parts are not covered by warranty unless the component part is found to be flawed. |

Q:What shall we need to do if we want to get a better quotation? |

|

A: If you want to get a suitable machine from us ,please let us know the details as follows: 2).the output size 3).the stone type |

Q:Can I visit your factory? |

A:Certainly,you are always welcome here to know more details and get more trust. |

CONTACT ME |

|

|

Mining Vibrating Screen is one of the unique product or equipment,Made in China vibrating screen/vibration sieve for powder/granule/liquid is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Made in China vibrating screen/vibration sieve for powder/granule/liquid is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,Made in China vibrating screen/vibration sieve for powder/granule/liquid is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Made in China vibrating screen/vibration sieve for powder/granule/liquid is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD