Rotary drum sawdust sieving machine / trommel screen / sand sieving machine

Product DescriptionSand sieving machine description

Sand sieving machine is a classification machine for various kinds of materials, for example: coal, river sand, ore, refractory materials, grape pomace, chemical, waste etc. It has features of low noise, good sealed, high efficiency, large capacity of classfication, long service life time etc.

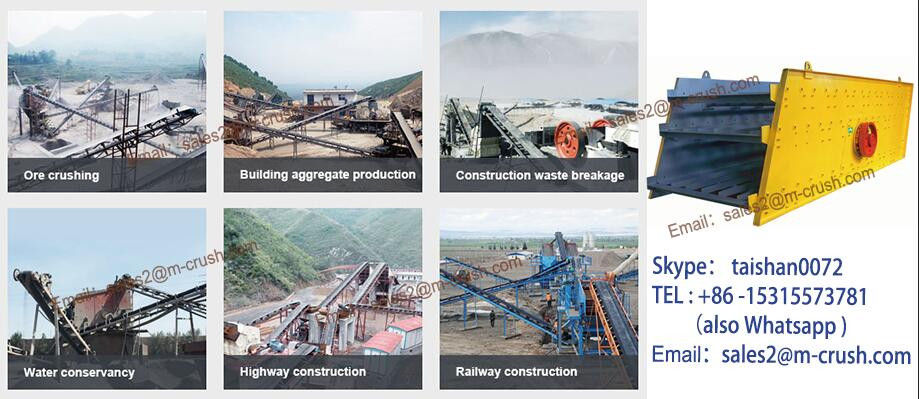

Application of sand sieving machine:

Sand sieving machine is widely used for screening and classifying mineral materials, such as metallurgy, mining, chemical, coal, building materials, abrasives, and other industries.

1.Quarry: suitable for screening and classifying gravel, clay, mountain meal, sand, etc.

2.Coal Industry: suitable for screening and classifying lump coal, coal dust, coal washing, etc.

3.Chemical, Mineral-selecting Industry: suitable for grading and classifying lump, powder substance, etc.

4. Metallurgy, construction and other industries.

5. Mining: alluvial gold, placer gold sand gold ,etc.

Working principle of sand sieving machine:

Sand sieving machine consists of five main parts as drum, frame, hopper, reducer and motor. After transporting materials into the drum, on one hand, materials will be classfied along with the rotation of drum, on the other hand, the bigger materials will flow forward along the direction of slope ( drum aslant angle is 7 degree) and be separated by the screen with different number of meshes. The different materials fall into different hopper and then be sent to different finished product stacks by manpower or belt conveyor or screw conveyor.

Technical parameter of rotary screen:

Model |

Capacity (m3/h) |

Drum Diameter (mm) |

Length of Screen Surface (mm) |

Deck (layer) |

Power (kw) |

GTS-600 |

1-5 |

600 |

1000-3000mm or as your requirements |

1-5 |

3 |

GTS-800 |

1-10 |

800 |

1-5 |

3 |

|

GTS-1000 |

20-30 |

1000 |

1-5 |

3 |

|

GTS-1200 |

20-50 |

1200 |

1-5 |

3 |

|

GTS-1500 |

40-80 |

1500 |

1-5 |

5.5 |

|

GTS-1800 |

80-150 |

1800 |

1-5 |

7.5 |

|

GTS-2000 |

130-200 |

2000 |

1-5 |

11 |

Remarks:

1 ) This is only for reference, such as different raw material will have different capacity

2)The length of screen surface is customized according to customer requirement, and is related to the sifting ratio.

3) According to the difference of working environment, the trommel screen can be equipped with vibration motor(indoors) or diesel engine(outdoors)

4) Dust-collecting device, hopper, belt conveyors can be provided as requested.

Spiral Rotary Screen economical & efficient classification, Screening and grading

Spiral Rotary Screen low noise, less dust

increase product grade, while allows rapid and large volume processing.

this type drum screen trommel screen used for placer gold sand gold

new customized for our clients

Include single, double, and muti layer type

with stairway, more safe

Packaging & Shipping

Export Country

Mexico, Ghana, Australia, Qatar, Tajikistan, India, Azerbaijan, Vietnam, Kazakhstan, Mongolia, Ecuador, Iran, Pakistan, the Middle East and other countries and areas.

Packing details:

1.Main machine is packed with plastic wrap or steel box,depends on the machine weight.

2.Electic motor is packed with steel box or wood box.

3.Motor control is packed with carton box.

4.Loaded container at factory.

Shipping ways:By sea ,by train ,by air or as your required deposit.

Delivery time :5 working days after receiving your 30%

Port:Qingdao ,Tianjin Shanghai or as required.

Payment Terms

1. Payment: T/T, L/C or as required

2. MOQ: 1set

3. Warranty : 12-18 months(wearing parts excluded)

We provide 12 months quality warranty to make sure your machine well run consistency.

1. Pre-sale service:

A.Professional engineer will project design, process design.

B.Recommend suitable equipment according to your special demand.

2. During-sale service:

We will accompany you to visit our factory and all kinds of machinery and equipment if you come here, also show you construction plan and assist in the development process in detail.

A.Pre-check product before delivery

B.Engineer’s guidance installation and adjustment.

C.Training operation and finishing the check to satisfying your requirement .

3. After-Sale services:

A.Common problem can be solved through in 24 hours .

B.We will reguRotary drum sawdust sieving machine / trommel screen / sand sieving machine contact our customers.

JINMA oversea friends

Zhengzhou Jinma Mining Machinery Co.,Ltd.

JINMA basic information:

Company development:Established in 1976 .

Company Tenet: Clients' interests first, quality first, after-sales service first

Company spirit:Founding Integrity, Innovation Forever

Company philosophy: Jinma makes employees as fundamental, as quality to development, improve benefit by management, with innovation to develop market, in good faith to famous brand and use good service to make development.

Company strategy: Advanced, scientific, novelty and practicability.

Company Goal:We manufacture lean products, To provide higher quality products to customers more high-quality service.

JINMA support and service:

1. Jinma provide the design, process diagram and foundation drawings according to clients' request.

2. Clients are welcome to inspect the equipment when the equipment are ready to delivery.

3. Equipment will be delivered with English Manuals and technical drawings

4. Engineers available to service machinery overseas, to make the layout design, foundations, guide the installation, commissioning run test, training workers, etc.

5.The equipment ordered from jinma will be guaranteed within 2 years since the day of purchasing if the problem is due to the equipment’s quality. If there is big quality problem with the equipment, the seller will discuss with the buyer and offer proposals to solve the problems within 72 hours since the notice from buyer.

6. Offer spares for the equipment within 10 years

JINAM advantages

1) our main productsjaw crusher, hammer crusher, PCZ heavy hammer crusher, DPC fine crusher, the PXJ third create sand machine, PCH ring hammer crusher, the PC hammer crusher and so on more than 30 varieties of broken machinery.

2) 38 years year of production experience

3) Processional Research and Development team

4) Strict quality control

5) We provide competitive prices, reliable quality products and swift delivery

6)the products are exported to Chile, Peru, Vietnam, Indonesia, Malaysia, India, the Philippines, Thailand, Laos, Russia, Turkey, Iran, north Korea, kazakhstan, azerbaijan, Latvia and so on ,more than 30 countries and regions.

JINMA WORKSITE

1.How long is the delivery time of your equipment?

The delivery time is within 30 working days. But when the project is very big and the customers have special requirement on the equipment, the delivery could be extended.

2.How long is the equipment warranty period?

Our equipment warranty period is 1 year. Wearing parts and problem coursed by worker’s wrong operation are not included.

3.What’s the after sale service of your company?

We will provide foundation drawing to the clients for installation. Besides, we can provide installation service, workers training service, etc.

4.Can you provide wearing parts?

We have two casting factories that specialize in produce wearing parts for our clients. If your equipment are not manufactured by our company, please provide us the wearing parts drawing.

5.Can you give me a solution and quotation?

Of course, to provide accurate solution and quotation, please give us background information, including, raw material, the capacity, max. input size, the output size, the usage of final products, etc.

JINMA certification

Mining Vibrating Screen is one of the unique product or equipment,Rotary drum sawdust sieving machine / trommel screen / sand sieving machine is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Rotary drum sawdust sieving machine / trommel screen / sand sieving machine is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,Rotary drum sawdust sieving machine / trommel screen / sand sieving machine is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Rotary drum sawdust sieving machine / trommel screen / sand sieving machine is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD