cement mill wear resistant steel plates screen plates

| Product Name | mining product service wear resistant steel plate riddle plate vibrating screen |

| Material | Q235/Q345+Chromium carbide overlay |

| Base metal | Q235/Q345 or customized |

| Hardfacing layer | Chromium carbide overlay |

| Chemical composition | C: 3.0-5.0 % Cr: 25-40 % |

| Hardness | HRC58-63 |

| Microstructure | Carbide (Cr7C3)volume fraction above 50 % |

| Wear resistance | High wear/abrasion resistance |

| Flatness tolerance | ±3 mm/m |

| Thickness tolerance | uniform overlay thickness, with tolerance within 0-0.5 mm |

| Impact resistance | Medium |

| Technology | Hardfacing, open arc welding, submerged arc welding |

| Plate Size | Cusomized sizes |

| Main thicknesses(base metal+overlayer) | Customized thicknesses. |

Company Information

Since 2004, Wodon has more than 200 employees.

Wodon product: flux cored welding wires, chromium carbide overlay steel plates, wear resistant partss, wear pipes, wear fittings.

Welding wire and wear plate workshops

Wodon's quality managment

Warehouse

How to contact us?

Packing & Delivery

Packing Details: steel pallets or plywood carton and pallets

1. Welding wire 50kgs package 2. Welding wire 150/200kgs packing 3. Welding wire 15kgs cement mill wear resistant steel plates screen plates packing

1. Welding wire 50kgs package 2. Welding wire 150/200kgs packing 3. Welding wire 15kgs cement mill wear resistant steel plates screen plates packing

4. Wear plate packing 5. Nude plate on pallet packing 6. Film wrapped wear parts packing FAQ

4. Wear plate packing 5. Nude plate on pallet packing 6. Film wrapped wear parts packing FAQQ: Are you trading company or manufacturer ?

A: We are ISO certified flux cored welding wire and CCO wear plate factory.

Q: Are you able to produce customized chemical composition and dimension?

A: Yes, we could offer special welding wire and wear plate according customers' requirement.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-45 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A: Payment=1000USD, 20~30% T/T in advance, balance against the copy of BOL. Other payment terms are negotiable.

Q: Do you provide after-sales service ?

A: Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

If our product meets your interest, please feel free to contact us as follow:

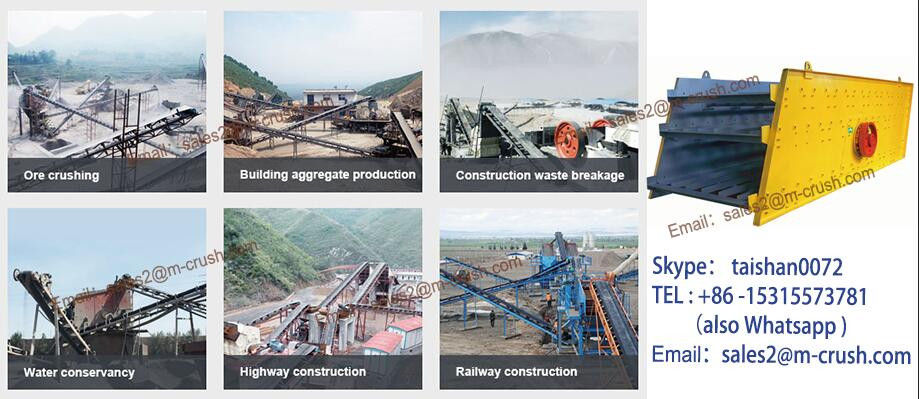

Mining Vibrating Screen is one of the unique product or equipment,cement mill wear resistant steel plates screen plates is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

cement mill wear resistant steel plates screen plates is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,cement mill wear resistant steel plates screen plates is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

cement mill wear resistant steel plates screen plates is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD