SYT ultrosonic rotary vibrating screen filter

Ultrasonic Rotary Vibrating Working Principle High Screening Precision Rotary Powder Industrial Ultrasonic Vibrating Screen: The ultrasonic vibrating wave (mechanic wave) added on the sieve mesh makes superfine powder accept the giant ultrasonic acceleration which restrains blockage factors which includes adhesion, friction, wedging etc and improves sieving and cleaning efficiency.

Features

A. The mesh does not block and it cab self-cleaning.

B. Bouncing balls and blocking device do not need.

C. Long service working life.

D. Ultrasonic Vibrating Screen is suitable for screening 40-635 mesh size, especially above 300 mesh.

E. The Sieve size can improve 1-70% and the capacity can improve maximum up to 10 times.

F. Ultrasonic Rotary Vibrating Screen has high screening efficiency, solve screening problems effectively

Such as strong adsorption, easy reunion, high electrostatic, high density, light proportion etc

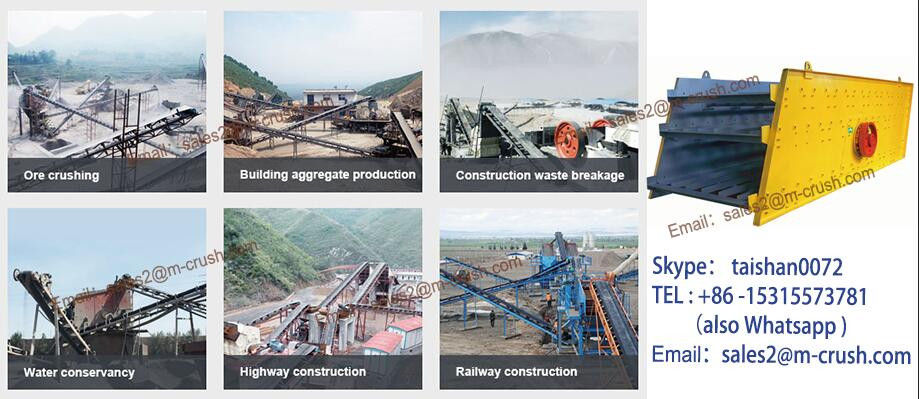

Application

1. Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

2. Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

3. Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice,

4. Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

5. Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

Technical parameters

Ultrasonic Vibrating Screen Technical Parameters | |||

Frequency |

34KHz |

Overall Dimension |

345mm*320mm*145mm |

Power |

220V~240V50/60HZ |

IP Code |

IP55 |

Working Mode |

Continuous |

Adjustment Range |

50~100% |

Temperature |

45°C |

Transducer |

Offset |

Products show

Packaging & Shipping

1. First, the vibrating screen empty running 48 hours before packing;

2. Then to observe whether the motor heating, the machine whether there is noise and so on;

3. Finally, to pack and shipment when fully meet requirements.

Pictures will be taken before delivery.

Our Services

1. Pre-sale service:

a. In order to let each customer know better about the performance and requirements, we provide these services

b. To send each potential customer the detailed production information and company profile

c. According the user’s different needs, we work to recommend and guide for them

d. To help them select the appropriate equipment

2. Service during sale:

a. Do good communication with customers, so that each part can exchange the information.

b. Deliver on time as per the contract clause.

3. After-sale service:

a. To track the customer’s feedback after receiving the equipment

b. Any product quality we receive, the technical personnel will guide to solve the problem

c. All the products have three guarantees

d. Provide technical exchanges

e. Do well about the work of maintenance and service

Company Information

Xinxiang city Sanyuantang Machinery Co.,Ltd, ISO9001 certified enterprise, specializes in manufacturing series of vibrating screen and vibrating machine and we could design, develop and produce by ourselves.

At present, the main range of products include kinds of series of Vibrating screens, Vibrating separator-filter, Ultrasonic vibrating screens, Sifting machines, Filtering machines, Linear vibrating screens, Testing screens, Vibrating conveyers, etc.

These products are highly suitable to the purpose of screening grains and powders and filtering serous fluids. Other uses include the sifting and sorting dry powders, liquids and solids in industries such as Chemicals, Food processing, Pharmaceuticals, Metallurgy, pigments, Ceramics and Abrasives, etc.

Our products have seven national patents. The quality and technology of our products have reached the international advanced standard.

Why Choos US

1. International high quality certification product chain

2. Manufacturer, more reasonable price

3. Solid technical support and after-sales service

4. Uphold the principle of “Customer Supreme”

5. Exports to more than 20 countries and regions, good customers feedback

6. One-stop service, customized exclusive project feasibility report.

Exhibition & Customers

Factory equipment

Certification & Honor

The main products

1. What it does?

a: Separate solids from liquids or segregate dry materials into various sizes.

2. How it works?

Vibration is accomplished by eccentric weights on the upper and lower ends of the motion-generator shaft. and The angle of lead given the lower weight with relation to the upper weight provides variable control of the spiral screening pattern.

3. Any self-cleaning devices on the sieving machine?

Yeah, Bouncing ball or Ultrasonic system could be installed.

4. How many kinds of material are supported?

A. All stainless steel (201, 304, 316L)

B. All carbon steel Q235A

C. Contact part Stainless steel.

5. About the phase and the voltage?

A. 0.12-0.55 kw single phase and three phase are both supported.

B. 0.55-2.2 kw Three phase is just supported.

C. 110V, 220V, 380V, 415V, 450V, 480V are supported. (50HZ OR 60 HZ).

6. How long is the warranty?

The warranty is 12 month(except the wearing parts includes sealing strip, bounce ball and sieve mesh, etc.). Because different usage, the wearing parts will have different life.

7. OEM order and labeling services are supported?

Yeah, OEM order and labeling services are supported. And we seek global partners.

8.How to select a suitable vibrating screen?

1. what’s the material and its density?

2. what’s the mesh size? And which size of powder do you need?

3. What’s the percentage of every size in your material?

4. What’s your excepted capacity?

9. Whether the site visits is supported or not?

Yeah, site visits will be highly welcome. Airpo picking up and hotel booking are both supported. half hour ZHANGZHOU international Airport .

Welcome to visit our factory

Contact me

Mining Vibrating Screen is one of the unique product or equipment,xinxiang Professional Mechanical Ultrasonic Oscillating Screen is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

xinxiang Professional Mechanical Ultrasonic Oscillating Screen is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,xinxiang Professional Mechanical Ultrasonic Oscillating Screen is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

xinxiang Professional Mechanical Ultrasonic Oscillating Screen is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD