Why SBM vibrating screen is popular in the world ?

The reason:The outstanding features this mahine from SBM.

1.Easy to transport

2.Greatly reduce material transportation cost

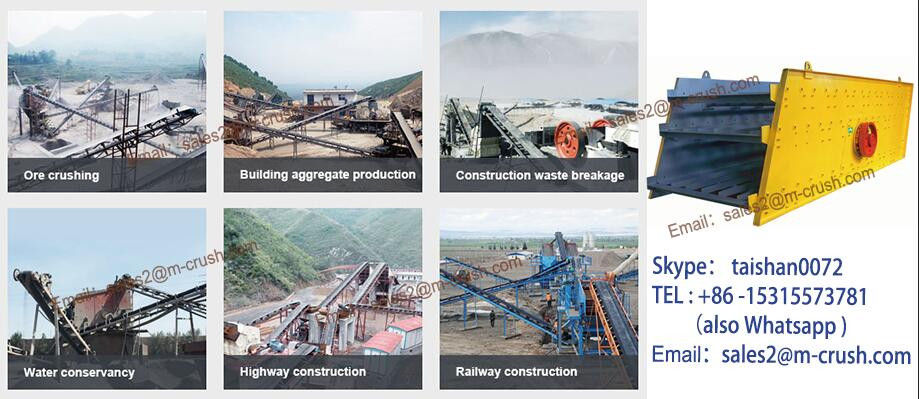

3.Wide applications

4.Reliable performance and convenient maintenance

5.Customized production and flexible configuration

SBM insists on providing clients with overall solutions from equipment recommendation to debugging and installation, worker training, technical support and maintenance.

Supply small vibratory sieve , vibrating sand screen , linear vibrating screen :

small vibratory sieve , vibrating sand screen , linear vibrating screen --- Vibrating screen is the circular vibrating type; we called it circular vibrating screen also. SBM’s vibrating screen earns this name by reason of its approximately circular movement. Vibrating screen is of multilayer and high efficient. The eccentric shaft vibration exciter and partial block help to adjust amplitude. This kind of vibrating screen is of long streamline, clear screening for different specifications.

Supply small vibratory sieve , vibrating sand screen , linear vibrating screen application:

small vibratory sieve , vibrating sand screen , linear vibrating screen --- Vibrating screens are widely used for grading and screening materials in such fields as chemical industry, minerals, quarry, building materials, water conservancy and hydropower, transportation, smelting and so on. Vibrating screens are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc. There are 40 specifications for this series vibrating screen, of which the heavy duty type of vibrating screens are for the classification of large size materials, while the light duty type of vibrating screens are for the middle and small size materials.

Supply small vibratory sieve , vibrating sand screen , linear vibrating screen frequently questions :

Q: “What’s the advantages of screen of your company manufactured?”

A: Screen is the main wearing parts. According to the material variety and user requirements, can be woven high manganese steel mesh, perforated metal and rubber sieve sieve sieve surface with both single and double, can meet all kinds of sieve screening efficiency, long life Without pore blocking requirements.

Q: “What’s applicable industry of vibrating screen used?”

A: Vibrating screen is suitable used in quarry aggregate screening, but also for coal preparetion, mineral processing, building materials, electricity and chemical industries for product grading. High efficiency, also suitable for mining, sand and gravel industry

Supply small vibratory sieve , vibrating sand screen , linear vibrating screen features :

1. This series of vibrating screens use eccentric block to produce strong exciting force.

2. Crossbeam and the main body of the vibrating screen are connected with high strength screw bolts. So our vibrating screens have the features of simple structure and easy maintenance.

3. The vibrating screen adopts tire coupling with capability of flexible connection and stable operation.

4. SBM’s vibrating screens adopt the structure of small amplitude, high frequency, large obliquity to make the screen hold the capability of high efficiency, large handling capacity, long life span, low consumption, and little noise; you will find this series of vibrating screen optimized for your demands.

Supply small vibratory sieve , vibrating sand screen , linear vibrating screen technical data:

Supply small vibratory sieve , vibrating sand screen , linear vibrating screen working principle:

small vibratory sieve , vibrating sand screen , linear vibrating screen --- Vibrating screen moves round. It has multi-layers and is of high efficiency. The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line. In screen grading, the material is separated mechanically on screen plates. Rolling bearings in vibrating screens are stressed by high, mostly shock-type loads. Moreover, the bearings, while rotating about their own axis, perform a circular, elliptical or linear vibrating motion. This results in high radial accelerations which additionally stress the bearings, and especially the cages, considerably. The operating speeds are usually very high. As a result, the bearing temperatures are up to 20 to 30 degrees Kelvin higher than in normal applications. In addition, considerable misalignments between the bearing locations and considerable shaft deflections have to be accommodated.

Mining equipment: small vibratory sieve , vibrating sand screen , linear vibrating screen

Vibrating screen main parts:

Vibrating screen is made up of screen meshes, spring, support frame and so on.

We also offer spare parts and original wear parts related to the vibrating screen.

Operation and maintenance of small vibratory sieve , vibrating sand screen , linear vibrating screen :

1. Before starting, we should inspect every fasteners bolt of vibrating screen whether to become less crowded, if it has, we should fasten it one time.

2. After the sieve machine has empty motion for 4-6 hours, the sieve body should be steady. No sway and unusual sound and driver bearing temperature≤7512.

3. After idle operation movement, we should examine every spots spiral of vibrating screen fastens one time.

4. In normal work, it should have periodic inspection of every fasteners bolt tight situation.

5. Inspect vulnerable, the use and the maintenance frequently, please refer to the instruction for use. (vibrating motor should be refueled one time after 3 months, driver be refueled one time every month, a minor repair half year, a overhaul one year.)

6. Before parking, you should stop giving the material first and waiting for the screening surface material to walk.

7. When the vibrating screen working, you should observed the sieve machine operational aspect continuously, if there are not normal movements or unusual sound about the vibrating screen, should shutdown the machine and check, discover the reason then remove difficulty.

Project Case

Screening plant, separating plant

Crushing & screening for sale

Kinds of crushing and screening equipment such as jaw crusher, cone crusher, impact crusher, mobile crusher ,vibrating screen is designed for coal processing etc.

Crushing equipment , grinding equipment for coal processing plant Crushing equipment , grinding equipment for coal processing plant

Features & Advantages:

- High quality dressing equipment;

- Installation Services & Automation & Instrumentation service;

- Spare parts and consumables parts support.

Coal crushing plant:

SBM is a major coal crusher and coal crushing plant manufacturer and supplier in the world, SBM coal crusher is the best machine for sizing coal for fire power plants and coke ovens, SBM coal crusher plant also is versatile that it limestone for blast furnaces, and crushing a wide range of raw and manufactured materials for industry including refractory bricks, cemented carbide and diatomaceous earth.

As coal is the most major non-renewable fuel all over the world from ancient to now, In order to make full use of coal and reduce the pollution of the environment,after the coal have been mined, people usually crush the larger coal block to small one by coal crushing plant, use coal mill or coal pulverizer to grind the coal.

Coal crushing plant manufacturer:

SBM produces a low cost, maintenance-free coal crushing machine. The coal crusher equipment was used to crush coal into small pieces. We can supply the clients with stationary coal crusher and mobile coal crusher, both can equip with vibratory screen and belt conveyor.

As a coal crusher plant manufacturer and supplier, SBM can supply different types of coal crusher used as coal processing equipment according to the clients’ needs. It contains jaw crusher for coal, impact crusher for coal, mobile crusher for coal, belt conveyor for coal, vibratory screen for coal,vibrating screen for coal etc.

What our customers say:

" We take mobile crushing and screening plant for large scale coal crushing production. " ---- India Customer

Clients Comments

- "We have decided to increase the purchasing of SBM Machinery as it chases what it says is highly efficient and environmental friendly." - Client From Zimbabwe

- "Cooperating with SBM brings us more opportunities to maximize our production. Especially its small vibratory sieve , vibrating sand screen , linear vibrating screen and coal mills just match our plant." - Mr. Bruce Munro, Chief Executive Mining - Client From Australia

- "Dealing with SBM Machinery especially small vibratory sieve , vibrating sand screen , linear vibrating screen trading is the best choice since i started importing & exporting of mining equipment." - Clients From South Africa

- "The company is worth a win-win business of mining equipment after i was touched by their small vibratory sieve , vibrating sand screen , linear vibrating screen service." - Clients From India

Company Information

ABOUT US

SHANGHAI SHIBANG MACHINERY CO., LTD is one high-tech enterprise, which involves R&D, production, sales and service as well. In the past 20 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making high grade sand and matched equipments.

The head office of SBM is in Shanghai- the international financial centre. Here we have modern production base of 2.3 million square meters, professional R&D institution and technology team, which make us world-class company. Here all SBM machines are designed produced, assembled and texted according to the ISO9001:2008.

Till now, our products are sold to 130 countries, being the popular equipments in global crushing and grinding industry. With the development of our SBM, we would like to help more and more customers start their business in mining and construction industries, offer them the best solution, much more advanced machinery and better service.

SUPPORT

We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

After-sales service support

After we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the product you purchased properly to your hands.

We will send a professional and high levels installation engineer team at the same time the product properly to the destination, in order to supply you a full range of products installation services. For some typical problems, our rigorous installed engineers also will do some certain installation debugging training, etc.

Technological support

SBM has been largely adopting new technologies, new techniques and high-tech equipments. And SBM also has strict and effective quality control system. We have obtained ISO9001:2000 quality system certificate.

SBM insists on providing clients with overall solutions from equipment recommendation to debugging and installation, worker training, technical support and maintenance.

FAQ

Why Choose Us?

We have a professional installation and after-sales staff,

We have the largest factories and production capacity,

We have a professional sales and service team,

The SBM machine, worthy of your trust!

Inquiry Service

Your email address and telephone will not be shared or published!

| Products: |

Please Select! ♥Mobile Crusher ♥Jaw Crusher ♥Cone Crusher ♥Impact Crusher ♥VSI Crusher ♥Hydraulic Cylinder Cone Crusher

♥Vertical Mill (LM) ♥MTW European Grinding Machine ♥Ultrafine Mill(XZM)

♥Sand Washing Machine ♥Vibrating Screen ♥Vibrating Feeder ♥Belt Conveyor

♥Stone processing production line ♥Industrial milling production line ♥Beneficiation Production Line ♥Not Sure |

| Materials: | ♥ ♥ ♥ ♥ ♥ |

| Capacity: | |

| Use Place: | As South Africa. |

| Name:* | As Mario. |

| Email:* | |

| Phone:* | |

| Message:* | As : input size/output size like 0-10,15-20mm for crushing 0r 75 microns(200meshes) for grinding mill machine and other requirements. |

Please tell us:Products *---raw material *---the capacity per hour/day *---input size *---output size * | |

...

Mining Vibrating Screen is one of the unique product or equipment,Supply small vibratory sieve , vibrating sand screen , linear vibrating screen is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Supply small vibratory sieve , vibrating sand screen , linear vibrating screen is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,Supply small vibratory sieve , vibrating sand screen , linear vibrating screen is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Supply small vibratory sieve , vibrating sand screen , linear vibrating screen is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD