Mining Vibrating circular Screen For Quarry Stone ClassifyingAApplicationApplication

Mining Vibrating circular Screen For Quarry Stone Classifying. A deck moves in a circle. It operates with a continuous feed rather than in batches, Mining Vibrating circular Screen For Quarry Stone Classifying to much greater output. The incline allows the feed to move through the device. A circular vibrating screen is a screening machine employed in processes involving particle separation. In particle processes screening refers to separation of larger from smaller particles in a given feed, using only the materials’ physical properties.

SStructureStructure

The circular vibrating screen adopts the vibration exciter with barrel type of eccentric shaft and block to adjust the swing. The vibration exciter is installed on the lateral plate of the sieving box. The motor makes the exciter swing round speedily through tire coupling. The continuous forced circular motions of sieving box were achieved through the powerful centrifugal force. Materials in the sieve case can be separated and screened from the sieve pore in this process.

| model | screen layers | screen size (mm) |

Max feed size (mm) |

capacity (t/h) |

Vibrating frequency (Hz) |

Power (KW) |

weight (t) |

Dimension (mm) |

| 3YK-1245 | 3 | 1200×4500 | 200 | 15-80 | 16.2 | 11 | 4.807 | 5600×1800×1850 |

| 2YK-1548 | 2 | 1500×4800 | 200 | 30-180 | 13-16 | 15 | 5.800 | 5906×2100×1600 |

| 3YK-1548 | 3 | 1500×4800 | 200 | 30-200 | 13-16 | 15 | 6.866 | 5906×2100×1900 |

| 4YK-1548 | 4 | 1500×4800 | 200 | 30-250 | 13-16 | 18.5 | 7.360 | 5906×2100×2150 |

| 2YK-1854 | 2 | 1800×5400 | 250 | 50-300 | 16.2 | 18.5 | 6.769 | 6509×2536×1810 |

| 3YK-1854 | 3 | 1800×5400 | 250 | 50-300 | 16.2 | 22 | 8.285 | 6509×2536×1910 |

| 4YK-1854 | 4 | 1800×5400 | 250 | 50-300 | 16.2 | 30 | 9.796 | 6509×2536×2250 |

| 2YK-2160 | 2 | 2100×6000 | 250 | 100-400 | 16.2 | 30 | 9.680 | 7150×2670×2120 |

| 3YK-2160 | 3 | 2100×6000 | 250 | 100-400 | 16.2 | 30 | 10.206 | 7150×2670×2270 |

| 4YK-2160 | 4 | 2100×6000 | 250 | 100-400 | 16.2 | 30 | 11.800 | 7150×2670×2650 |

| 2YK2460 | 2 | 2400×6000 | 300 | 150-600 | 16.2 | 30 | 10.200 | 7150×2900×1950 |

| 3YK-2460 | 3 | 2400×6000 | 300 | 150-600 | 16.2 | 30 | 12.350 | 7150×2900×2350 |

| 4YK-2460 | 4 | 2400x6000 | 300 | 150-600 | 16.2 | 37 | 13.850 | 7150×2900×2680 |

| 2YK-2665 | 2 | 2600x6500 | 300 | 250-700 | 16.2 | 37 | 14.260 | 7120x3120x2310 |

| 3YK-2665 | 3 | 2600x6500 | 300 | 250-700 | 16.2 | 45 | 15.850 | 7120x3120x2820 |

| 4YK-2665 | 4 | 2600x6500 | 300 | 250-700 | 16.2 | 45 | 17.600 | 7120x3380x2870 |

| 2YK-2865 | 2 | 2800x6500 | 350 | 300-800 | 16.2 | 22x2 | 16.570 | 7500x3400x2280 |

| 3YK-2865 | 3 | 2800x6500 | 350 | 300-800 | 16.2 | 22x2 | 17.728 | 7500x3400x2470 |

| 4YK-2865 | 4 | 2800x6500 | 350 | 300-800 | 16.2 | 22x2 | 18.144 | 7500x3480x2830 |

| YK-3070 | 1 | 3000x7000 | 350 | 400-900 | 16.2 | 22x2 | 14.086 | 8000x3860x1890 |

| 2YK-3070 | 2 | 3000x7000 | 350 | 400-900 | 16.2 | 22x2 | 15.899 | 8000x3860x2280 |

| 3YK-3070 | 3 | 3000x7000 | 350 | 400-900 | 16.2 | 22x2 | 18.350 | 8000x3860x2478 |

1.What is the classify materials ?( ore,stone ,sand, sifting and others ) |

2.What is the handling capacity of per hour? |

3.What is the size and how many different size want to get from vibrating screen ? |

AAbout UsAbout Us

AAbout UsAbout Us Xinxiang Jin Rui Machinery Factory was established in 1999 year, located in Xinxiang city.

1. Jinrui company has standard workshop of 3000 square meters.

2. Jinrui company has passed ISO9001 quality management system certification .

3. Main products: the conveying and lifting equipment of large angle belt conveyor,

DT series fixed belt conveyor, screw conveyor, mobile conveyor, chain plate conveyor,

bucket chain conveyor, bucket elevator,chain bucket elevator

1. Quality control

All the equipment offered by Henan Deya Machinery Co., Ltd. are produced by China national standard drawings, nonstandard equipment will be produced by the drawings confirmed by clients. Deya Machinery strictly follows ISO 9001: 2008 Quality management system. Most equipment will be test for at least 8 hours in the factory before delivery. There is record in computer for each equipment, spares can be easily confirmed when it is necessary.

2. Way of payment

Welcome clients place the order by Mining Vibrating circular Screen For Quarry Stone Classifying online one-touch! Deya also offers various ways of payment, T/T, against copy of B/L, L/C, D/A, D/P, West union, etc. All can be negotiated.

3. Delivery time

Normal delivery time within 10 to 20 working days, complete production line or larger equipment may take Mining Vibrating circular Screen For Quarry Stone Classifying. Exact delivery shall be confirmed when place the order.

4. Trade terms

Typically EXW, FOB, CIF, CFR, DAF follows International Rules for the Interpretation of Trade Terms 2010(INCOTERMS 2010).

5. Shipping lines

Priority rule based on clients' request, and freight cost, service, shipping date, date of arrival shall be considered.

6. Installation

Deya has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians’ round way air tickets, saMining Vibrating circular Screen For Quarry Stone Classifying(shall be confirmed before leaving), food and lodging, most importantly to guarantee the technicians’ safety.

7. Equipment warranty

Equipment from Henan Deya Machinery Co., Ltd. with 18 months warranty, can be extended to 24 months as request.

Any other misunderstand ,please don't hesitate to contact me

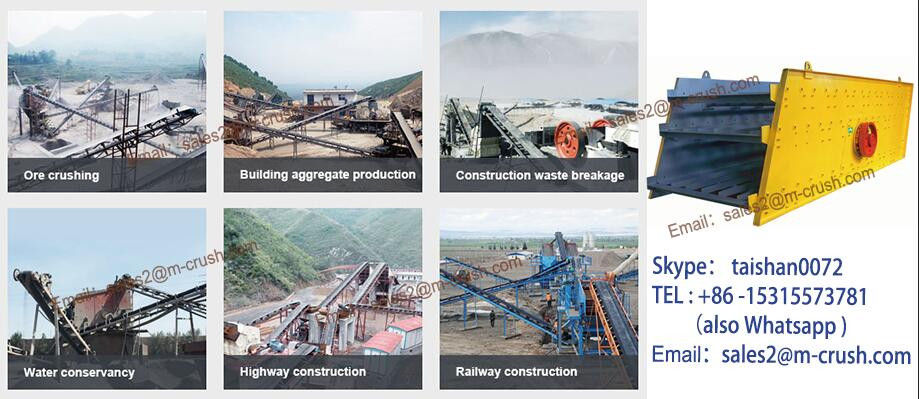

Mining Vibrating Screen is one of the unique product or equipment,Mining Vibrating circular Screen For Quarry Stone Classifying is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Mining Vibrating circular Screen For Quarry Stone Classifying is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,Mining Vibrating circular Screen For Quarry Stone Classifying is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Mining Vibrating circular Screen For Quarry Stone Classifying is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD