YK1545,YK1854,YK1860 High Quality Vibrating Screen For Crusher Plant Final Aggregate Size Separation

Product Description

Introduction of the high quality vibrating screen:

circular vibrating screen system to introduce German technology to produce efficient vibrating screen, adjustable amplitude, long material screening line, multi-layer screening, clear all specifications screening, screening efficiency. Suitable quarry screening aggregate, coal preparation, mineral processing, building materials, electricity and chemical industries are also available for product grading.

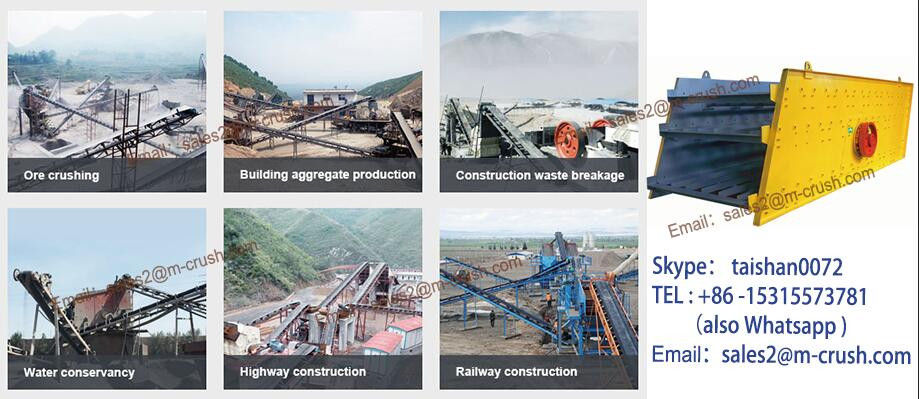

Application of the high quality vibrating screen:

Adapt material: basalt, river gravel, bluestone, iron ore, copper, steel slag, granite, limestone, concrete, lime, gypsum, lime, coal, aggregate production line.

Applications: quarry screening material stone design, also available for coal preparation, mineral processing, building materials, electricity and chemical sectors doing product grading.

Features of the high quality circular vibrating screen :

1. Using block eccentric as excitation force, strong exciting force;

2. sieve beams and screen box with high strength bolts links, no welding;

3. Sieve machine of simple structure, convenient maintenance;

4. Tire couplings, flexible connection, smooth operation;

5. Screening efficiency, large capacity, long life.

Composition of the vibrating screen :

Circular vibrating screen is mainly composed of screen box, screen mesh, vibrator, damping spring device, chassis. Cylinder eccentric shaft vibration exciter and partial block help to adjust the amplitude of the vibrator is mounted on the side panel of the screen box is rotated by the motor through the V-belt to produce centrifugal force, forcing the vibration of screen box.

The side panel of the screen machine made of high quality steel, side panels and beams, shaker base is made of high strength bolts or ring groove rivet connection.The vibrator mounted on the side plate of the sieve box, is rotated by a motor via a coupling, a centrifugal inertial force, forcing the sieve vibration.

Principle of high quality vibrating screen :

Motor through V-belt exciter eccentric block to produce the high-speed rotation. Operation of the eccentric block to produce great centrifugal force to stimulate sieve box to produce a certain amplitude circular motion, sieve material in the the tilt screen surface by the impulse to pass by the screen box and generate continuous movement of throwing materials with the screen surface meet manipulation smaller than the sieve particles through sieve, in order to achieve the classification.

Screen Mesh :

Factory view of vibrating screen :

Working site of vibrating screen :

Main parameters of vibrating screen :

Type |

Screen |

Layers |

Sieve |

Max. Feed |

Capacity |

Power |

Screen |

Weight(expect |

2YA1237 |

1200×3700 |

2 |

3-50 |

200 |

7.5-80 |

5.5 |

3.6 |

2.34 |

3YA1237 |

1200×3700 |

3 |

3-50 |

200 |

7.5-80 |

7.5 |

3.6 |

3.05 |

2YA1548 |

1500×4200 |

2 |

5-50 |

400 |

50-208 |

15 |

6.3 |

5.33 |

3YA1548 |

1500×4800 |

3 |

5-50 |

400 |

50-250 |

15 |

7.2 |

6.07 |

3YA1848 |

1800×4800 |

3 |

5-80 |

400 |

50-300 |

18.5 |

8.64 |

6.93 |

3YA1860 |

1800×6000 |

3 |

5-80 |

400 |

50-350 |

22 |

10.8 |

7.70 |

3YA2160 |

2100×6000 |

3 |

5-100 |

400 |

100-500 |

30 |

12.6 |

9.24 |

2YA2460 |

2400×6000 |

2 |

5-150 |

400 |

150-700 |

30 |

14.4 |

12.35 |

Packaging & Shipping

Zhengzhou YK1545,YK1854,YK1860 High Quality Vibrating Screen For Crusher Plant Final Aggregate Size Separationg Heavy Equipment Co.,Ltd

Zhengzhou YK1545,YK1854,YK1860 High Quality Vibrating Screen For Crusher Plant Final Aggregate Size Separationg is a joint stock corporation integrating scientific research, manufacture, marketing and exporting with the main target at the large and medium sized series of heavy duty equipments for mining, ore selecting, wall materials, formed coal, metallurgy and ect. The company located at Zhengzhou National YK1545,YK1854,YK1860 High Quality Vibrating Screen For Crusher Plant Final Aggregate Size Separation.

We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices. These products include Stone Crushers, Jaw Crushers, Cone Crushers, Hammer Crushers, and Sand making Machines, Sand Washing machines, Rod Mills, Powder making Machines, Ore Dressing Machines, Briquette Machines and complete Cement Output Lines. Our products have been sold to areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.

Our Workshop and Building

Our Production Capacity

Our Services

Our mission is providing our clients timely, rapidly, and efficiently services.

√ Rapid Reply

To the issue you propose, or the feedback, we are sure to make reply soon.

√ Providing Solution Design:

According to the results of communication with you, we will provide a design solution for you speedly.

√ Inspection Our Factory and Machines:

If you have interests, welcome to visit our factory and inspect the machine.

√ Order execution:

Provide equipment layout draw, foundation draw and detailed equipment manauls. Timely report you the manufacturing schedule and related photos.

√ Delivery fast:

We can arrange fast, safe shippment on time.

√ After-sales service:

If you need, we will dispatch engineer to the site to guide installation, debugging and training operators. Installation and operation workers are offered if you need

International Trade We treat visiting clients as our family!

Mobile phone : 0086 137 8347 1727 Skype /wechat : sarapang6email : sales006*zzhxmachine.com

Mining Vibrating Screen is one of the unique product or equipment,YK1545,YK1854,YK1860 High Quality Vibrating Screen For Crusher Plant Final Aggregate Size Separation is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

YK1545,YK1854,YK1860 High Quality Vibrating Screen For Crusher Plant Final Aggregate Size Separation is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,YK1545,YK1854,YK1860 High Quality Vibrating Screen For Crusher Plant Final Aggregate Size Separation is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

YK1545,YK1854,YK1860 High Quality Vibrating Screen For Crusher Plant Final Aggregate Size Separation is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD